The era of “promising” climate technology is over. We have entered the age of deployment. For years, the conversation around climate tech startups focused on potential—lab experiments and pilot projects that might one day save the world. But as we move forward, the narrative has shifted. The most exciting companies are no longer just pitching ideas; they are pouring concrete, commissioning factories, and delivering commercial products.

From decarbonizing “hard-to-abate” sectors like steel and cement to solving the intermittency of renewable energy, a new wave of innovators is rewriting the industrial playbook. These are not just science projects; they are the engines of a new, net-zero economy.

Key Takeaways: The State of Climate Tech

-

Heavy Industry is the New Frontier: The biggest venture capital dollars are no longer flowing to software, but to “hard-to-abate” sectors like green steel (Boston Metal) and low-carbon cement (Brimstone).

-

Storage Must Go Long: To kill coal plants, we need batteries that last for days, not hours. Iron-air technology (Form Energy) is the leading solution to this 100-hour gap.

-

Carbon Removal is Essential: Reducing emissions isn’t enough. Technologies that actively suck CO₂ from the sky (Climeworks) are moving from science fiction to commercial utility.

-

Circular Supply Chains: The green transition requires massive amounts of minerals. Recycling startups (Redwood Materials) are critical to preventing a new geopolitical crisis over mining rights.

-

The “Green Premium” is Shrinking: Innovations are successfully lowering the cost of green alternatives, moving them closer to price parity with fossil-fuel incumbents.

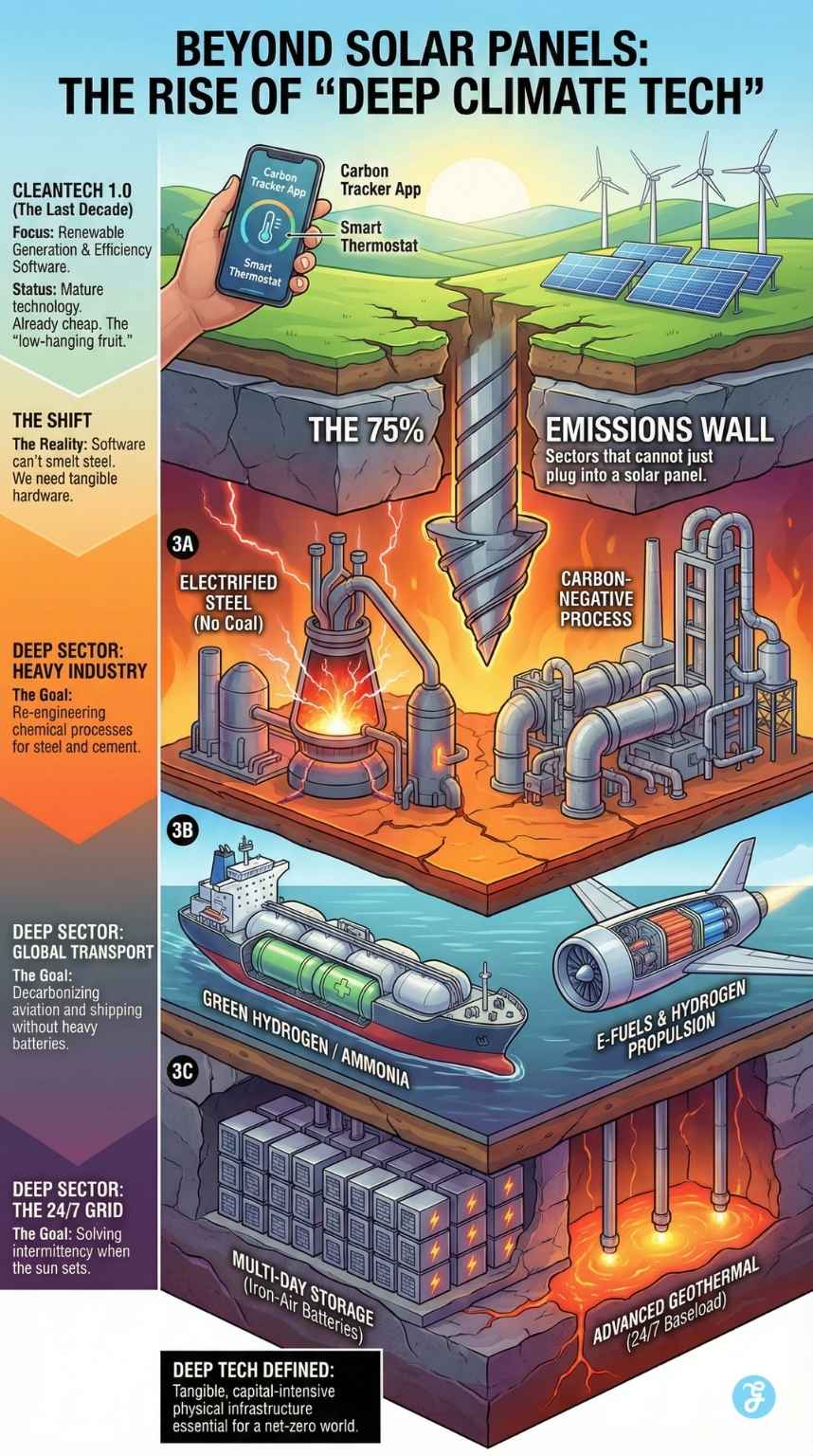

Beyond Solar Panels: The Rise of “Deep Climate Tech”

Before diving into the companies, it is crucial to understand the massive shift occurring in the industry this year. For the last decade, “cleantech” was dominated by software—apps for tracking carbon footprints or optimizing home thermostats. While helpful, these solutions didn’t touch the root of the problem.

In 2025, the focus has pivoted to Deep Tech—tangible, physical innovations that tackle the “hard-to-abate” sectors.

Why this shift? We have largely solved the easy stuff. Solar and wind are now the cheapest forms of electricity in history. The remaining 75% of global emissions come from sectors that cannot simply be plugged into a solar panel:

-

Heavy Manufacturing: Making steel and cement requires chemical reactions, not just power.

-

Long-Haul Transport: Planes and ships can’t carry heavy lithium batteries.

-

Grid Reliability: The sun goes down every night, creating a gap that fossil fuels currently fill.

The climate tech startups listed below were selected because they aren’t just making incremental improvements; they are physically re-engineering the industrial pillars of our modern world to function without fossil fuels.

The Heavy Industry Decarbonizers

Fixing the materials that build our world.

Heavy industry—specifically steel, cement, and industrial heat—is responsible for roughly 30% of global emissions. These sectors were once considered impossible to clean up. The following startups prove otherwise.

1. Boston Metal (Green Steel)

The Innovation: Molten Oxide Electrolysis (MOE)

Steel production traditionally relies on coal to strip oxygen from iron ore, a process that accounts for 7-9% of global CO₂ emissions. Boston Metal has developed a way to replace that coal with electricity. Their “Molten Oxide Electrolysis” process sends an electric current through molten iron ore, releasing pure oxygen as the only byproduct.

Why Watch Them Now:

In early 2025, Boston Metal celebrated the historic commissioning of their first commercial-scale MOE cell in Woburn, Massachusetts. While they are already generating revenue from high-value metals, they are on track to bring green steel to the mass market by 2026, aiming to revolutionize a trillion-dollar industry.

2. Brimstone (Green Cement)

The Innovation: Carbon-Negative Portland Cement

If cement were a country, it would be the third-largest emitter in the world. Brimstone has cracked the code by producing “Ordinary Portland Cement”—the industry standard—without releasing CO₂. Instead of heating limestone (which releases carbon), they use calcium silicate rocks. Their process creates magnesium byproducts that actually absorb CO₂ from the air, making their cement potentially carbon-negative.

Why Watch Them Now:

Crucially, Brimstone received third-party certification confirming its product is chemically identical to the cement builders already use. With significant federal investment secured recently, they are scaling up production to prove that green concrete doesn’t require new safety codes—just new supply chains.

3. Antora Energy (Industrial Heat)

The Innovation: Thermal Batteries

Wind and solar power are great, but factories need intense, continuous heat (often 1500°C+) to melt glass or smelt metals. Antora Energy solves this by using renewable electricity to heat massive blocks of solid carbon until they glow white-hot. These “thermal batteries” store energy as heat, which can be discharged on demand to power heavy industry 24/7.

Why Watch Them Now:

Antora is currently operating a factory in California to produce these thermal units at scale. By providing a cost-effective way to electrify industrial heat, they are removing the last excuse for factories to burn natural gas.

The Grid & Energy Revolutionaries

Making clean energy reliable, everywhere, all the time.

To rely on renewables, we need to store energy for days when the sun doesn’t shine and the wind doesn’t blow.

4. Form Energy (Energy Storage)

The Innovation: Iron-Air Batteries

Lithium-ion batteries are excellent for EVs but too expensive for long-duration grid storage. Form Energy has resurrected a century-old idea: the iron-air battery. By utilizing the process of rusting (and un-rusting) iron, their batteries can store energy for 100 hours at a fraction of the cost of lithium.

Why Watch Them Now:

Form Energy’s “Form Factory 1” in West Virginia is now operational and expanding. With major utility contracts signed and a new project announced in Maine, they are actively solving the intermittency problem that has plagued the renewables sector for decades.

5. Fervo Energy (Geothermal)

The Innovation: Enhanced Geothermal Systems (EGS)

Traditional geothermal energy works only where hot springs naturally exist. Fervo Energy uses precision horizontal drilling techniques—adapted from the oil and gas industry—to create geothermal reservoirs anywhere there is hot rock beneath the surface. This unlocks a practically limitless source of 24/7 carbon-free electricity.

Why Watch Them Now:

Fervo recently closed a massive $462 million Series E funding round to scale their “Cape Station” project in Utah. Once complete, it will be the world’s largest next-generation geothermal project, proving that clean baseload power is scalable.

| Startup | Sector | Key Technology |

| Form Energy | Grid Storage | Iron-Air Battery (100-hour storage) |

| Fervo Energy | Geothermal | Horizontal Drilling for 24/7 Power |

| Brimstone | Construction | Carbon-Negative Portland Cement |

| Boston Metal | Manufacturing | Green Steel via Electrolysis |

| Twelve | Aviation Fuel | CO₂ into Jet Fuel (E-Jet) |

The Carbon Removers & Transformers

Cleaning up the mess we’ve already made.

Reducing new emissions isn’t enough; we must also remove existing CO₂ from the atmosphere and stop digging up fossil carbon.

6. Climeworks (Direct Air Capture)

The Innovation: Direct Air Capture (DAC)

Climeworks is the household name in carbon removal. Their massive collector machines act like giant vacuums, filtering CO₂ directly from the ambient air. This captured carbon is then mixed with water and pumped deep underground, where it reacts with basaltic rock to turn into stone within a few years—permanently removing it from the atmosphere.

Why Watch Them Now:

Their “Mammoth” plant in Iceland is the largest facility of its kind in the world and is currently ramping up operations. As they push toward megaton-scale removal, Climeworks is setting the standard for high-quality, verifiable carbon removal credits.

7. Twelve (Sustainable Fuels)

The Innovation: Carbon Transformation (Industrial Photosynthesis)

We still need carbon for jet fuel and plastics, but we don’t need to get it from oil wells. Twelve uses an electrochemical reactor to break apart CO₂ and water, rearranging the atoms into essential chemicals and fuels. They call this “industrial photosynthesis.”

Why Watch Them Now:

Twelve’s commercial-scale plant in Moses Lake, Washington, is a game-changer for aviation. Producing their trademarked “E-Jet®” fuel, they offer airlines a drop-in replacement for fossil kerosene that lowers lifecycle emissions by over 90%.

Next-Gen Transport & Circular Economy

Moving people and materials sustainably.

The transition to electric vehicles (EVs) and green aviation requires new supply chains and novel propulsion systems.

8. ZeroAvia (Hydrogen Aviation)

The Innovation: Hydrogen-Electric Powertrains

Batteries are too heavy for commercial flight, but hydrogen offers a lightweight solution. ZeroAvia is retrofitting aircraft engines with hydrogen fuel cells that generate electricity to power the propellers. The only emission is water vapor.

Why Watch Them Now:

ZeroAvia recently received “Design Organisation Approval” from the UK regulators—a critical safety milestone. With their 600kW engines advancing through FAA certification, they are on the cusp of enabling zero-emission regional flights for commercial passengers.

9. Redwood Materials (Recycling)

The Innovation: Closed-Loop Battery Supply Chain

Founded by Tesla co-founder JB Straubel, Redwood Materials is tackling the “dirty secret” of green tech: mining. They recycle end-of-life EV batteries to recover up to 95% of critical minerals like lithium, cobalt, and nickel. They then refine these materials into anode and cathode components for new batteries.

Why Watch Them Now:

Having raised another $350 million in late 2025, Redwood is expanding its Nevada campus to become a domestic manufacturing giant. By localizing the supply chain, they are reducing reliance on foreign mining and making the EV revolution truly circular.

The Future of Food

Feeding the world without eating the planet.

10. Meatable (Cultivated Meat)

The Innovation: Opti-Ox™ Technology

Industrial animal agriculture is a leading driver of deforestation and methane emissions. Meatable grows real pork and beef muscle from a single cell sample, without slaughtering animals. Their proprietary “Opti-Ox” technology allows them to differentiate cells into muscle and fat faster and more cheaply than competitors.

Why Watch Them Now:

Following their acquisition of Uncommon Bio to boost efficiency, Meatable is moving closer to price parity with conventional meat. With regulatory approvals for cultivated meat expanding globally (including recent wins in Australia and Asia), Meatable is poised to bring guilt-free sausage and steak to supermarket shelves.

The “Valley of Death”: Roadblocks to Watch

While the technology is ready, the path to commercialization remains perilous. In venture capital, this phase is known as the “Valley of Death”—the gap between a successful pilot project and a profitable factory.

As we watch these 10 startups, three major hurdles stand in their way:

-

The Green Premium: Can they lower costs fast enough? For example, green steel is currently 20-30% more expensive than fossil-fuel steel. Until that gap closes, adoption will rely on government subsidies.

-

Grid Connection Queues: You can build a massive battery factory, but you can’t turn it on if the local utility company takes five years to upgrade the power lines. Grid congestion is currently the #1 bottleneck for climate tech deployment in the US and Europe.

-

Supply Chain Wars: Companies like Redwood Materials are racing to secure minerals, but geopolitical tensions over lithium and copper could slow down production targets for everyone.

The “Methodology” Note

Selection Methodology: This list focuses on “Series B” to “Growth Stage” companies that have moved beyond the laboratory phase.

Companies were evaluated based on three criteria:

1) Scalability: (potential to reduce gigatons of emissions)

2) Commercial Traction: (active partnerships or factories built by 2025)

3) Funding Stability: (recent successful capital raises in a tight market)

Frequently Asked Questions (FAQs)

1. What is the difference between CleanTech and Climate Tech?

While often used interchangeably, there is a nuance. CleanTech typically refers to efficiency and renewable energy generation (like solar panels and water treatment). Climate Tech is a broader umbrella that specifically focuses on mitigating greenhouse gas emissions and addressing the impacts of global warming, covering everything from carbon capture to geoengineering and sustainable agriculture.

2. Why are “hard-to-abate” sectors so difficult to decarbonize?

Sectors like steel, cement, and aviation are called “hard-to-abate” because their emissions don’t just come from energy use; they come from the chemical processes themselves. For example, making cement releases CO₂ as a chemical byproduct, even if the factory runs on 100% solar power. Fixing this requires inventing entirely new chemistries, not just changing the power source.

3. Are these climate tech startups publicly traded?

Most of the companies on this list (like Form Energy, Northvolt, and Redwood Materials) are currently private startups funded by venture capital. However, many are eyeing Initial Public Offerings (IPOs) in the coming years as they scale up commercial production.

4. How does Direct Air Capture (DAC) actually work?

Think of DAC as a giant tree that works thousands of times faster. Machines draw in ambient air and pass it through a chemical filter that selectively binds with CO₂. The air is released back into the atmosphere cleaner, while the trapped CO₂ is heated, concentrated, and then either stored underground or used to make products like sustainable aviation fuel.

5. What is Green Hydrogen?

Green hydrogen is a clean fuel produced by using renewable electricity to split water into hydrogen and oxygen (electrolysis). Unlike “gray” hydrogen, which is made from natural gas and pollutes heavily, green hydrogen creates zero emissions. It is considered the “Swiss Army Knife” of decarbonization because it can fuel ships, heat factories, and store energy.

Bottom Line: The “Missing Middle” is Being Filled

The significance of these 10 climate tech startups lies in their focus. They are not building better solar panels (which are already cheap); they are targeting the “missing middle”—the heavy, complex, and expensive industrial processes that were previously ignored.

For investors, policymakers, and citizens, 2025 serves as a proof point. We now have the technology to make steel without coal, fly planes without oil, and store wind power for a week. The challenge is no longer invention; it is acceleration. These are the companies leading the charge.