Steel production has been one of the most significant sources of carbon emissions for a long time. Nowadays, as the industrial impact on the environment becomes a more frequent topic of discussion, steel producers are switching to more sustainable solutions. Companies are delivering exactly what customers are looking for: more products that are kind to our earth.

Steelmakers want to go green, and Nucor stands as a prime example of this industry transformation. This article reveals their key methods for reducing environmental impact while maintaining production efficiency.

Embracing Eco-Friendly Technologies

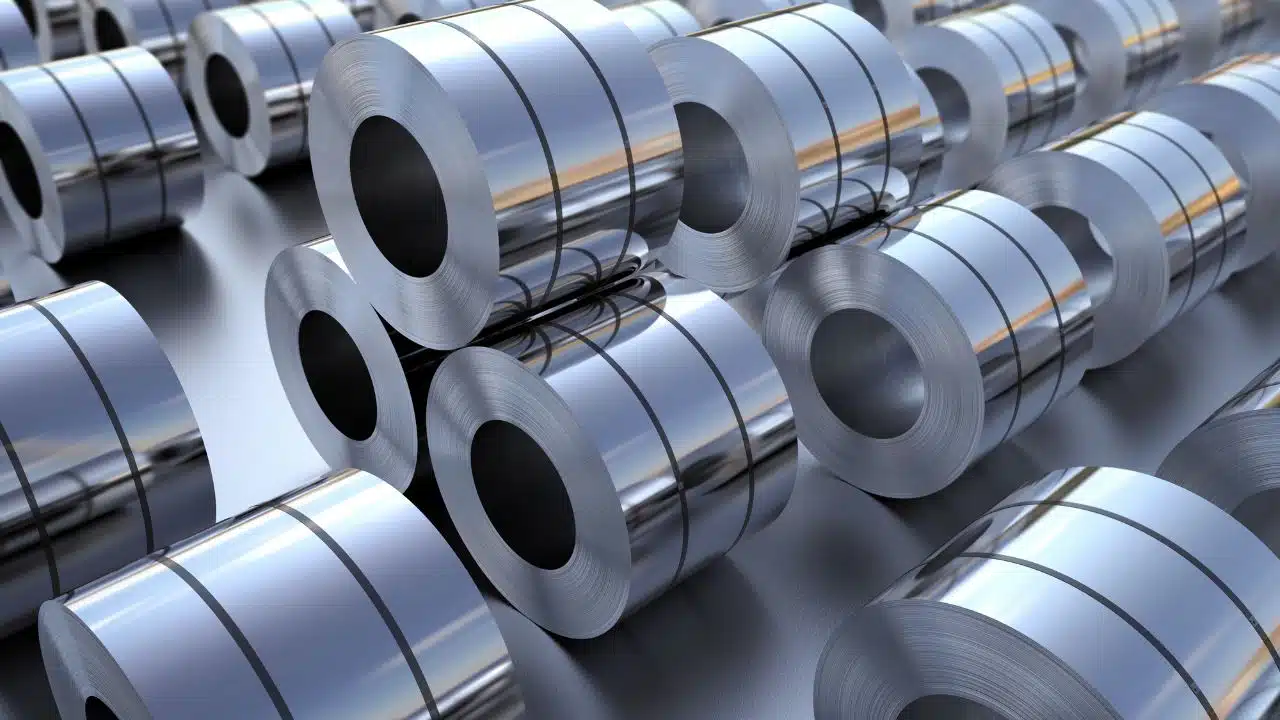

One of the most significant sources of emissions from steel production is the use of older technologies. Nowadays, leading companies are switching to more advanced and cleaner solutions to produce the material. Electric arc furnaces are highly popular because they are highly efficient and use recycled scrap metal to produce the material. This way, producers decrease the need for new raw materials and slash emissions by significant margins, as every ton of steel produced using recycling technology saves over a ton of CO2.

Recycling and Reuse of Materials

Another critical source of the carbon impact of steel producers is mining. By increasing the share of recycled materials in production systems, companies also decrease carbon emissions. Nowadays, most leading producers are trying to establish closed-loop production systems where all waste products are recycled and reused within the same technological process. Recycling old metal means using fewer fresh materials from the Earth.

Energy Efficiency

Energy efficiency is another quality that leading steel companies emphasize. New technologies and approaches to production allow for lower emissions per ton. For instance, heat recovery systems allow companies to capture and reuse energy that was previously wasted. Companies report that this solution simultaneously elevates overall company valuation by refining processes and increasing output significantly.

Transportation and Logistics Optimization

To reduce emissions, transportation logistics can be optimized. To shrink their environmental footprint, companies now map out the smartest delivery paths. Plus, they deploy trucks and vans that barely consume fuel. You can see the industry taking real steps to lessen its environmental impact.

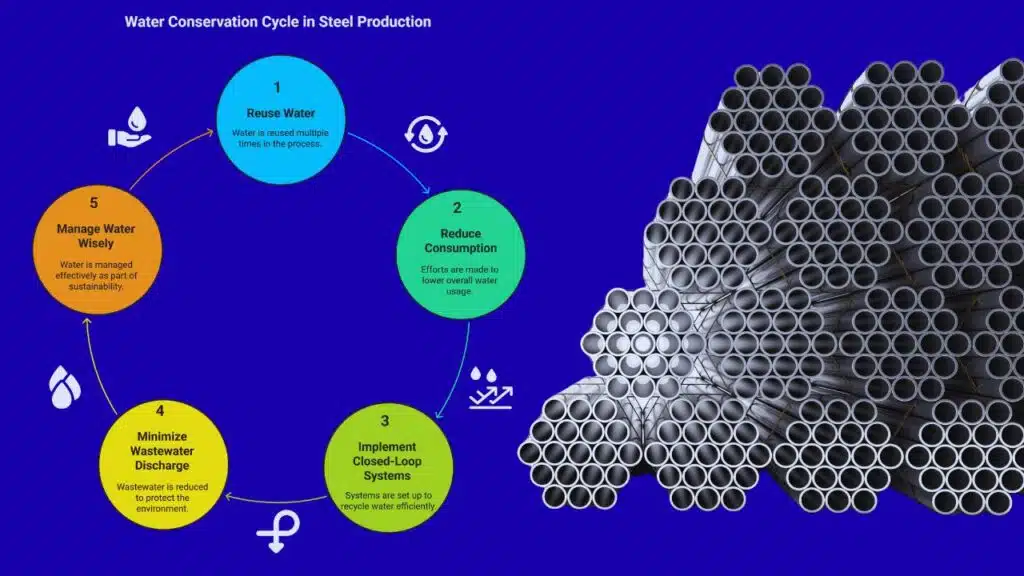

Reducing Water Usage

There’s a rising focus on water conservation in steel production. Traditional processes require substantial water usage, causing depletion of resources. Sustainable producers work hard to reuse water whenever possible and reduce consumption levels.

Closed-loop systems allow water to be reused several times before treatment and discharge. Such methods reduce wastewater discharge while conserving water. According to the Environmental Protection Agency, managing water wisely forms the backbone of any comprehensive sustainability plan.

Encouraging Industry Collaboration

Sustainability can only be driven through collaboration within the industry. Producers are now working together, sharing best practices and building cutting-edge tools. This collaborative approach allows the industry to accomplish greater environmental progress than any company acting alone.

Team projects also clear the path by making green practices the new standard. This means all producers could follow a unified plan to cut emissions, measuring progress against industry-wide goals rather than individual company metrics. Teaming up on innovative solutions accelerates the adoption of cleaner technologies across the sector.

Educating and Engaging Stakeholders

Perhaps the most important factor for industry progress is educating stakeholders about new sustainable technologies and practices. Companies are bringing together suppliers, customers, and staff to tackle environmental challenges. Sustainable and eco-friendly workplace policies help every part of a company support environmental initiatives.

Educating the public involves organizing interactive seminars, providing specialized instruction, and initiating broad outreach efforts. When stakeholders appreciate the value of sustainability, their support and input are more likely to be gained. Companies working together demonstrates serious commitment to reducing their carbon footprint.

Takeaways

Making steel production cleaner seriously shrinks the carbon footprint of the entire planet. Innovation, recycling, energy efficiency, and collaboration are helping tremendously, and producers are already showing excellent results. Environmentally sustainable practices that yield economic benefits come from such dedicated efforts.

As long as steel sectors keep investing in sustainability, they may set an example in environmental leadership. Shrinking our carbon impact means building a better, greener tomorrow for everyone.