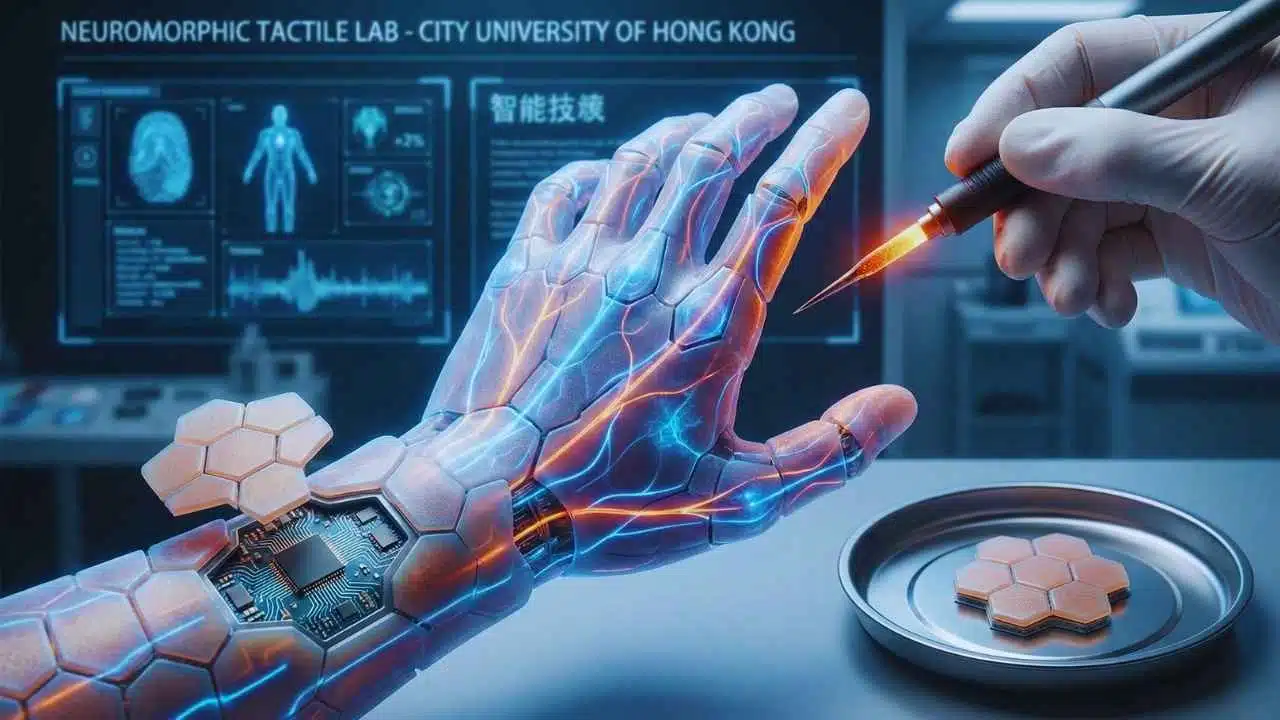

Pain sensing electronic skin developed by Chinese researchers grades pressure into “pain levels” and adjusts for temperature changes, aiming to make humanoid robots and prosthetics safer in real-world contact.

What China’s Pain-Sensing Electronic Skin Is And Why It Matters?

Chinese researchers have reported a new form of pain-sensing electronic skin designed to move beyond basic “touch detection” and into something closer to a safety reflex.

In everyday terms, most robot skins can tell when something touches them. Fewer can reliably judge when contact is becoming harmful. The new approach tackles that gap by converting pressure signals into graded warning levels, inspired by how medicine evaluates pain intensity.

That distinction matters because humanoid robots are being built for environments that are unpredictable and shared with people. A robot working in a warehouse, hospital, or home must be able to:

- Hold objects firmly without crushing them.

- Detect sharp or excessive pressure early.

- Reduce force fast when contact becomes risky.

- Stay reliable even when temperature changes affect materials and sensor readings.

The researchers position the technology as a potential building block for humanoid robotics, intelligent prosthetics, medical monitoring, and human-computer interaction—fields where safe physical contact is not optional.

How The Pain-Sensing Electronic Skin Works In Plain Language?

The reported system is not just a flexible sensor sheet. It is an end-to-end setup that combines sensing hardware with signal handling and software interpretation.

At a high level, the electronic skin is described as a modular system made up of four key parts:

- Sensor layer that detects pressure as an electrical change

- Signal acquisition electronics that collect and transmit those readings

- Neural-network processing that converts raw readings into graded “pain” levels

- Feedback/visual output that shows the final classification (the “pain grade”)

A core idea is that “pain” here functions like a risk label. Light touch may register as safe contact. Higher pressure crosses thresholds and gets classified into stronger warning bands. The goal is to produce outputs that are actionable for machines—signals that can trigger “back off,” “reduce grip,” or “stop” behaviors.

The design also draws from how human skin works. Human skin includes multiple receptor types. Mechanoreceptors help detect touch and pressure, while nociceptors respond strongly to potentially harmful stimuli. The new e-skin aims to replicate that protective logic: not just sensing contact, but identifying contact that could cause damage.

What The System Is Built To Do?

| Function | What It Means | Why It Helps |

| Touch detection | Senses pressure/contact | Enables basic tactile awareness |

| Pain grading | Converts pressure into multiple risk levels | Allows nuanced safety responses |

| Temperature adaptation | Maintains stable interpretation across temperature shifts | Reduces false alarms and missed hazards |

| Feedback output | Displays warning level in an easy-to-read form | Supports testing, monitoring, and control integration |

Why Temperature-Adjusted Pain Signals Are A Practical Breakthrough?

A major problem in soft sensors is that they can drift when the environment changes.

Flexible materials expand, soften, stiffen, or change electrical properties with temperature. If a robot’s “skin” interprets pressure differently on a hot day than a cold day, it can become unsafe. A system that is too sensitive can panic and stop constantly. A system that is not sensitive enough can miss dangerous contact.

That is why the researchers emphasize adaptive adjustment of pain perception based on environmental temperature using neural-network processing. The aim is a stable output: the same real-world force should map to the same warning level, even as surrounding conditions shift.

In practice, this kind of temperature-aware interpretation is especially relevant for:

- Factories and warehouses with large temperature swings.

- Outdoor robotics exposed to daily heat and cold.

- Wearable prosthetics affected by body heat, sweat, and changing ambient conditions.

- Service robots moving between air-conditioned and non-conditioned spaces.

The deeper point is trust. If tactile safety signals behave consistently, engineers can actually wire them into reflex-like robot controls without constant re-calibration.

How It Fits Into The Bigger Electronic-Skin Race?

China’s pain-sensing electronic skin is part of a wider global push to give robots richer body awareness—something closer to human skin, which combines touch, pressure, temperature, and protective responses.

Across research labs worldwide, several parallel directions are advancing quickly:

- Touch vs. noxious pressure separation: Some systems focus on distinguishing normal contact from harmful pressure, often using different sensing mechanisms across pressure ranges.

- Neuromorphic and brain-inspired interpretation: Another major direction is using “neuromorphic” approaches—hardware and algorithms inspired by how the nervous system processes sensory information. The idea is to interpret tactile data efficiently and in real time.

- Self-healing durability: Researchers are also addressing a practical weakness: e-skins can fail under cuts, punctures, abrasion, and repeated strain. Self-healing designs aim to recover function after damage, making sensors usable in harsh environments.

This matters because “robot skin” is not one invention. It is a stack of challenges: materials, sensors, wiring, signal stability, processing speed, and long-term robustness.

Different Meanings Of “Pain” In Electronic Skin Research

| Approach | What “Pain” Means Here | Typical Goal |

| Threshold-based pain | “Pain” triggers when force crosses a danger limit | Simple safety stop/reflex |

| Graded pain (this work’s direction) | “Pain” is multiple levels, like medical pain scales | Nuanced control and safer interaction |

| Learned/neuromorphic pain | “Pain” is interpreted by brain-inspired processing | Fast, efficient real-time responses |

| Damage-aware skin | “Pain” includes recognizing damage and surviving it | Reliable use in harsh, contact-heavy tasks |

What Comes Next For Humanoid Robots, Prosthetics, And Safety Standards?

Pain-sensing electronic skin is promising, but several real-world hurdles stand between a lab prototype and daily deployment on humanoid robots.

Scaling up is the first challenge. Small sensor arrays can demonstrate the concept, but humanoid robots need large-area coverage—hands, arms, torso, and sometimes the whole body. Scaling increases wiring complexity, noise, and processing load.

Durability is another major issue. Real-world robots face friction, impacts, oils, dust, moisture, sweat, and repeated bending. If an e-skin works only in clean conditions, it won’t become a standard component.

Calibration and meaning also matter. A “pain level 2” must reliably mean the same thing after weeks or months, across temperature changes, and across manufacturing variations. Without standardization, pain grading becomes hard to trust in safety-critical interaction.

Integration into robot control loops may be the most important step. The value of graded pain sensing is realized when robots can automatically respond:

- Reduce grip force when pressure approaches risk.

- Pause motion when skin detects abnormal contact.

- Retreat when contact becomes sharp, crushing, or repetitive.

- Log events for safety audits and improvement.

Finally, there is the communication challenge. The word “pain” can mislead. In robotics, “pain” typically means a protective signal—like an alarm or hazard rating—not a claim that machines feel suffering. Clear language will be essential as this technology enters public-facing humanoid products.

A Simple Timeline Of The Field’s Direction

| Year | What Advanced | Why It Matters |

| 2024 | More sensors that distinguish normal touch from harmful pressure | Better safety logic at the sensor level |

| 2024 | Stronger push for self-healing, tougher e-skins | Practical durability for daily use |

| 2025 | More neuromorphic and neural-network interpretation in e-skins | Smarter, faster signal understanding |

| 2025 | Pain grading paired with temperature adaptation | More stable safety signals in real environments |

If pain-sensing electronic skin can scale, stay stable, and survive daily wear, it could become one of the most important safety layers for humanoid robots. The long-term impact is not just “more sensitive touch,” but more reliable judgment about when touch becomes dangerous—and what to do next.