When it comes to protecting hardwood floors, the debate of oil vs water based polyurethane is the single most critical decision you will make. It determines not just how your floors look today, but how they will wear, age, and perform over the next decade. If you are looking for the short answer, Oil-based polyurethane offers a traditional, amber-hued finish that is softer and more flexible, while high-end water-based polyurethane provides a harder, clearer, and more durable finish that is environmentally safer and dries significantly faster.

In 2026, the flooring industry has shifted dramatically. The old wisdom that “oil lasts longer” is no longer the default truth. With advances in two-component waterborne technology and tightening environmental regulations across the USA, the landscape has changed. This guide dives deep into the chemistry, durability, cost, and aesthetics of both finishes to help you make the right choice for your home.

Key Takeaways

-

Durability: High-end “2-Component” water-based poly is now as durable, if not more so, than oil-based poly.

-

Aesthetics: Use Oil for a warm, amber, vintage look. Use Water for a natural, clear, or modern look.

-

Time: Water-based allows you to move back in within days; Oil requires weeks for full curing.

-

Health: Water-based is the only choice for those sensitive to fumes or concerned about VOCs.

-

Cost: Expect to pay a premium for high-quality water-based finishes, but the longevity and convenience are worth the investment.

The Evolution of Floor Finishes: Why the Gap Has Closed

A decade ago, the advice from any seasoned flooring contractor was simple: “If you want it to last, choose oil.” Back then, early water-based formulations were notorious for chipping, peeling, and wearing down within a few years. They were the “eco-friendly” option, but certainly not the durable one.

However, as we move through 2026, chemical engineering has leveled the playing field. The introduction of isocyanates and cross-linking hardeners in waterborne finishes has created a product that rivals the toughness of traditional oil finishes. Consequently, the decision is no longer just about which finish is “stronger”—it is now a nuanced choice about your lifestyle, your aesthetic vision, and your tolerance for chemicals in your home.

Choosing between oil vs water based polyurethane is no longer a question of “good vs. bad.” It is a question of “classic vs. modern.” Before we dive into the specific performance metrics, let’s look at the high-level differences to see which profile matches your project needs.

At a Glance: The Core Differences

Before we dissect the technical details, here is a quick comparison to help you orient yourself.

| Feature | Oil-Based Polyurethane | Water-Based Polyurethane (High-Grade) |

| Primary Base | Mineral Spirits / Petroleum | Water / Acrylic & Urethane Resins |

| Color Profile | Ambers/Yellows over time (Patina) | Dries Clear & Stays Clear (Non-yellowing) |

| Drying Time | Slow (8-10+ hours per coat) | Fast (2-4 hours per coat) |

| Curing Time | 30 Days | 3-7 Days (with hardener) |

| VOC Levels | High (Strong Fumes) | Low (Minimal Odor) |

| Durability | High Scratch Resistance (Flexible) | High Dent/Wear Resistance (Hard) |

| Cost | Cheaper Material, Higher Labor Time | Expensive Material, Lower Labor Time |

| Best For | Dark Woods, Walnut, Red Oak, Budget | Light Woods, Maple, Gray Stains, Pets |

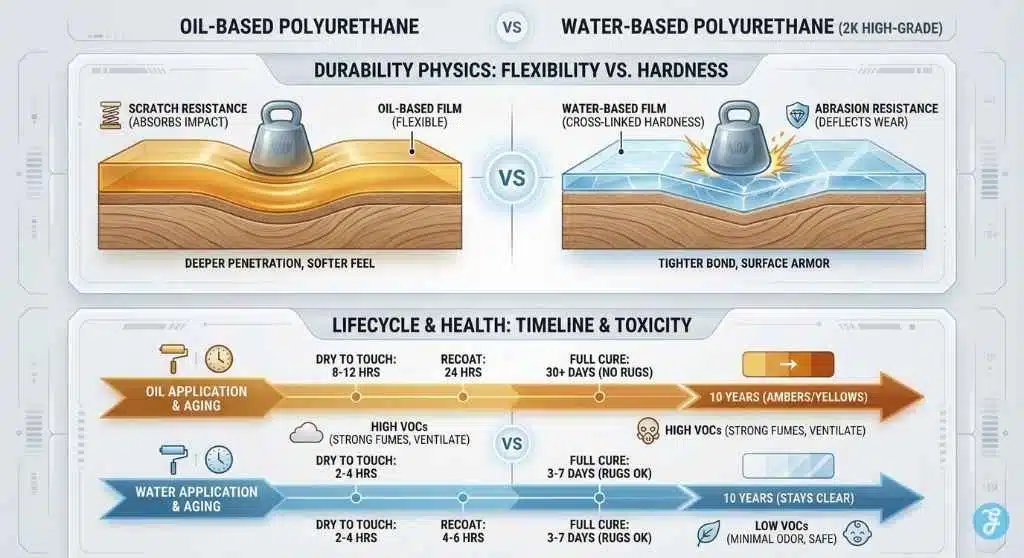

The Durability Debate: Hardness vs. Flexibility

The most common question homeowners ask is, “Which one is stronger?” The answer in 2026 requires understanding the difference between hardness and flexibility.

The Chemistry of Oil-Based Durability

Oil-based polyurethane is essentially a plastic coating derived from petroleum. It has a high solid content (often 45-50%), meaning that when the solvent evaporates, a thick layer of protection remains.

-

The “Soft” Advantage: Oil-based poly is chemically softer. This might sound like a negative, but it is actually a strength. Because it is flexible, it can absorb impacts (like a dog’s claws or a dropped toy) by denting slightly rather than shattering or flaking.

-

Scratch Resistance: This flexibility gives it excellent scratch resistance. It acts like a shock absorber for your wood.

The Rise of Two-Component Water-Based Durability

In the past, water-based finishes were weak and prone to wearing through. That is no longer the case. The “Commercial Grade” water-based finishes used in 2026 are Two-Component (2K) systems. This means the contractor mixes a separate “hardener” (Isocyanate) into the finish just before applying it.

-

The “Hard” Advantage: This chemical reaction creates a cross-linked structure that is significantly harder than oil finishes.

-

Wear Resistance: While oil might handle scratches well, a high-end water-based finish is superior at resisting abrasion—the slow wearing away of the finish from socks and feet over the years. This is why you see water-based finishes in airports and malls.

The Verdict: If you have large dogs that scratch floors, oil might hide the marks better due to its amber color and flexibility. If you have a high-traffic kitchen where thousands of footsteps wear down the floor, a 2K water-based finish is the superior choice.

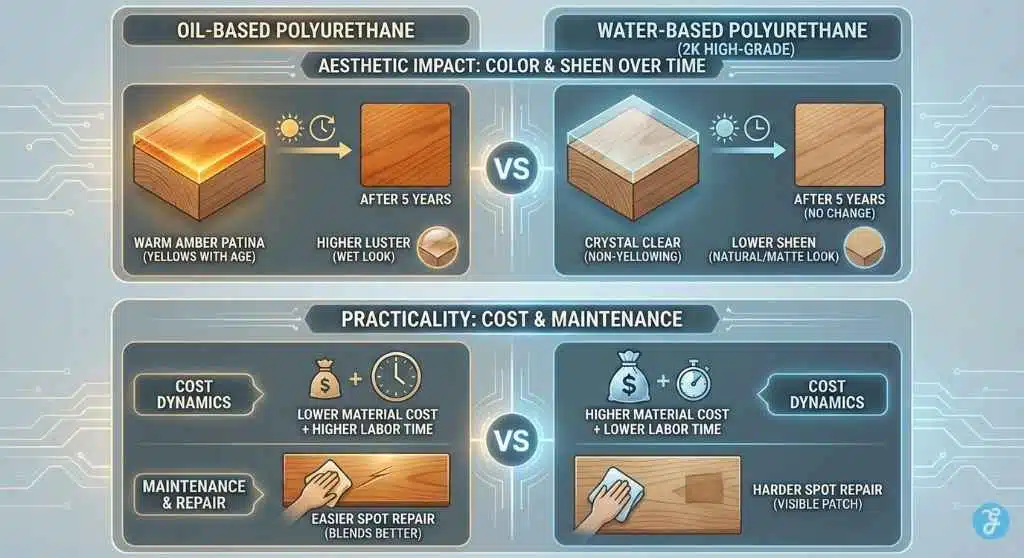

Aesthetics: The “Amber” vs. “Clear” Factor

Your choice of oil vs water based polyurethane should largely depend on the species of wood you have and the color palette of your home. The visual difference is drastic.

The Oil-Based “Glow”

Oil-based polyurethane is not clear; it is a translucent amber. When applied, it instantly warms up the wood, and as it ages and is exposed to UV light, it darkens into a rich, orange-gold patina.

-

Best Wood Pairings: This looks incredible on Red Oak, White Oak (if you like the traditional look), Walnut, and Brazilian Cherry. It highlights the grain and gives the floor a deep, 3D appearance.

-

The Warning: If you apply oil-based poly over a white or gray stain, it will turn the floor yellow. A chic “farmhouse gray” floor will look beige or greenish within a year.

The Water-Based “Invisibility”

Water-based polyurethane dries clear and stays clear. It does not yellow over time.

-

Best Wood Pairings: This is essential for Maple, Ash, and Hickory. These light woods look outdated and “gym-floor yellow” if finished with oil. Water-based finish preserves the natural, Scandinavian, raw-wood look that is popular in modern design.

-

Gray and White Stains: If you are staining your floors gray or white, you must use water-based polyurethane. It is the only way to lock in that cool tone without the finish ruining the color.

Health, Safety, and VOC Regulations

The conversation around oil vs water based polyurethane in the USA is heavily influenced by environmental laws. In 2026, many states have strict caps on Volatile Organic Compounds (VOCs).

The VOC Problem with Oil

Oil-based polyurethanes typically contain high levels of VOCs (often 350-500 grams per liter). These are solvents that evaporate into the air as the floor dries.

-

The Smell: The fumes are noxious and can linger for weeks. It is generally unsafe to sleep in the house while oil-based poly is drying.

-

Health Risks: Prolonged exposure to these fumes can cause headaches, dizziness, and respiratory issues.

-

State Bans: In states like California, New York, Massachusetts, and others in the Ozone Transport Commission, selling traditional oil-based poly in quarts or gallons is restricted or banned. Manufacturers have had to change formulas to comply, and many pros argue these “compliant” oil finishes are difficult to work with and dry too fast.

The Safety of Water-Based

Water-based finishes have very low VOCs (typically under 150-200 g/L).

-

Low Odor: The smell is faint and non-toxic. You can usually sleep in the house the same night the final coat is applied (in a different room).

-

Pet & Baby Safe: Because it cures so quickly, the floor effectively becomes inert and safe for crawling babies or pets within days, rather than off-gassing for a month like oil.

Drying and Curing: The Time Factor

For many homeowners, the decision comes down to logistics. How long can you be out of your house?

Oil-Based Logistics

-

Wait Time: You must wait 12–24 hours between coats.

-

Total Project Time: A standard 3-coat job takes 3 to 4 days just to apply.

-

Cure Time: It takes 30 days to fully cure. You cannot put area rugs down for a full month, or the floor will not breathe, and the finish will smudge.

Water-Based Logistics

-

Wait Time: You only wait 2–4 hours between coats. A pro can apply two coats in a single day.

-

Total Project Time: A 3-coat job can often be finished in 2 days.

-

Cure Time: High-end water finishes (like Bona Traffic HD or Loba 2K) are 90% cured in 72 hours. You can put rugs back down in less than a week. This is a massive convenience advantage for busy families.

Cost Analysis: Material vs. Labor

When you get a quote from a flooring professional, you might notice the price difference.

-

Oil-Based: The material itself is cheaper (approx. $40–$60 per gallon). However, because the drying time is long, the contractor has to drive to your house on 3 or 4 separate days. The labor cost is higher due to travel and extended project duration.

-

Water-Based: The material is expensive. A gallon of high-quality two-component water finish can cost $150–$200. However, the contractor can finish the job faster, reducing labor hours.

The Bottom Line on Price: usually, a water-based finish job will cost about 10-20% more total than an oil-based job, purely due to the high cost of the premium product. Do not try to save money by asking for “cheap” single-component water-based poly from a big-box store—it will not last.

Common Application Mistakes

If you are DIYing or hiring a pro, be aware of these pitfalls.

“Grain Raise” with Water

Because water-based poly contains… well, water, it can cause the wood fibers to swell and stand up, making the floor feel rough. This is called “grain raise.”

-

The Fix: A professional knows to “water pop” the floor or apply a sealer first, and then buff the floor between coats to knock down the grain for a smooth finish.

Poor Adhesion with Oil

If you don’t sand the floor perfectly or if there are contaminants (like wax or Pledge) on the old floor, oil-based poly can have trouble bonding (fish-eyes).

-

The Fix: Thorough screening and cleaning with mineral spirits before application is mandatory.

Environmental Impact & Sustainability

In 2026, sustainability is a major semantic topic in construction.

-

Oil-based relies on limited fossil fuel resources and contributes to ground-level ozone (smog).

-

Water-based technology is moving toward renewable resources. Some modern hardeners are increasingly bio-based. Choosing water-based is the “Green Building” standard (LEED compliant).

Sheen Levels: The Finish Factor

The chemical makeup of oil vs water based polyurethane doesn’t just change the color; it changes the way light hits the floor. In 2026, the trend is heavily shifting toward low-sheen finishes, and the two products handle this differently.

-

The “Oil” Sheen: Oil-based finishes naturally have a higher luster. Even a “Satin” in oil-based poly will often look semi-glossy for the first few months until it wears in. It has a “wet look” that many traditionalists love.

-

The “Water” Sheen: Water-based finishes are excellent at achieving a true Matte or Extra Matte look. Because the liquid is clearer, a matte water-based finish looks almost invisible, making the wood look raw and natural.

-

The “Satin” Difference: If you ask for “Satin,” be aware: an Oil Satin will shine more than a Water Satin. If you want a modern, low-luster look that hides dust and scratches, a high-grade water-based Matte or Satin is the superior choice.

Maintenance & Repair: Living with Your Floors

Once the fumes have cleared and the trucks have left, how do you actually live with these floors?

-

Cleaning: Both finishes require a pH-neutral hardwood floor cleaner (like Bona or Loba). Never use oil soaps, wax, or steam cleaners on either finish. However, water-based finishes are generally more sensitive to ammonia-based cleaners, which can cloud the clear film.

-

Repairability: This is where oil-based has a slight edge. Because it wets the wood and ambers it, blending a repair (spot-fixing a scratch) is somewhat easier. You can often lightly sand a spot and dab new oil on it.

-

The “Sock” Test: Water-based finishes (especially 2K) can feel slightly more “grippy” or rubbery under socks compared to the slick, hard-plastic feel of oil-based poly. This is often safer for kids and elderly family members as it provides better traction.

FAQ: Frequently Asked Questions

1. Can I switch from oil-based to water-based polyurethane when refinishing?

Yes, absolutely. You can apply water-based polyurethane over an old oil-based floor, provided the floor has been properly sanded down to raw wood. If you are just doing a “screen and recoat” (adding a top layer without sanding to bare wood), you must ensure the old oil finish is fully cured and chemically compatible. Using a bonding primer is often recommended in this scenario.

2. Does water-based polyurethane look “milky”?

In the bottle, yes, it looks like milk. However, it dries crystal clear. If it looks milky on your floor after drying, it usually means it was applied too thick, or it was applied over a dark stain without enough drying time, trapping moisture. A “sealer” coat is usually applied first to prevent this.

3. Which finish is better for pets (dogs/cats)?

For pets, a High-Traffic Water-Based Finish (Two-Component) is generally better. It is harder and resists the wearing-down friction of paws better than oil. Furthermore, because it has no toxic fumes, it is safer for pets who spend their lives with their noses close to the floor.

4. How many coats of polyurethane do I need?

-

Oil-Based: Typically requires 2 to 3 coats. Because the solid content is higher, you build up a thick film faster.

-

Water-Based: Typically requires 3 to 4 coats. Since the layers are thinner, you need an extra coat to achieve the same level of physical protection.

5. Why is my contractor pushing me to use water-based?

It is likely not just for the upsell. Contractors prefer water-based finishes because it allows them to work faster (finish your job in 2 days vs 4), it is healthier for their lungs, and they don’t have to worry about the “yellowing” complaints that often come with oil-based finishes on modern floors. It is the industry standard for a reason.

Final Thoughts: Making the Right Investment for Your Home

Choosing between oil vs water based polyurethane is not just a technical decision; it is a lifestyle choice. While the romantic allure of oil-based finishes—with their deep, rich patina and lower upfront cost—still holds a distinct place in restoration projects and traditional homes, the industry momentum in 2026 is undeniably favoring water-based technology.

If you value air quality, speed, and preserving the natural color of your wood, a high-quality two-component water-based finish is the gold standard. It is the finish that will stand up to the rigors of modern life while keeping your home safe from toxic off-gassing. However, if you are matching existing floors in a historic home or you crave that specific amber warmth that only time and oil can provide, traditional polyurethane remains a valid, time-tested contender.

Ultimately, the “best” finish is the one that aligns with your timeline, your budget, and your vision. Whichever you choose, ensure you are hiring a professional who understands the specific application requirements of that product. Your floors are the largest piece of furniture in your home; they deserve a finish that protects them for the long haul.