Ever wait for a package that takes days to reach your door? City traffic and long miles make same-day delivery hard. You want your items fast, but you watch trucks crawl in gridlock.

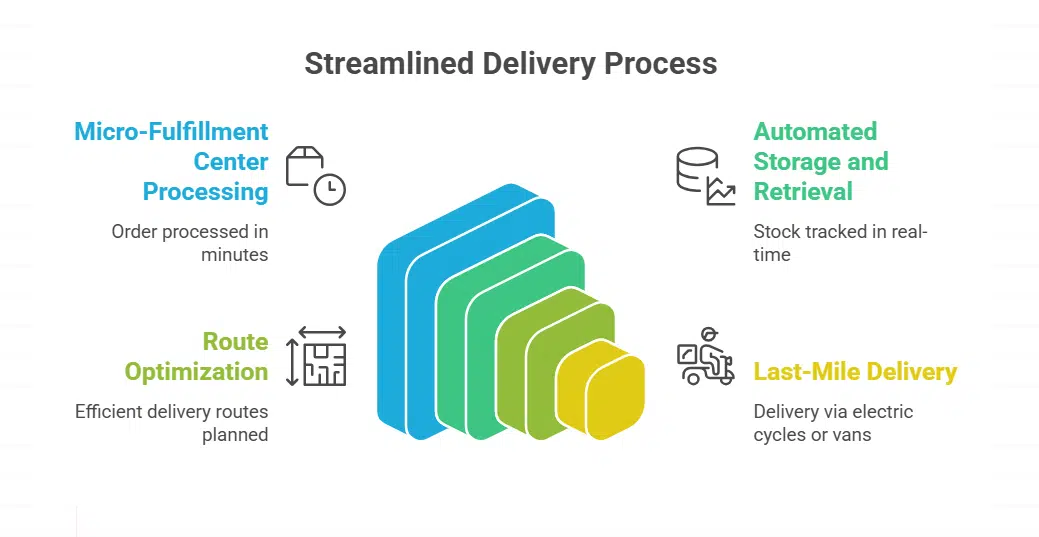

Micro-fulfillment centers use warehouse management systems. They add Internet of Things sensors and automated storage and retrieval systems. They speed up same-day delivery. They slice through traffic like a hot knife through butter, then feed orders to electric vehicles and autonomous vans for smooth last-mile delivery.

This post will show five ways these centers reshape urban logistics, cut traffic jams, and shrink carbon footprints. Keep reading.

Key Takeaways

- Micro-fulfillment centers use robots, IoT sensors, and automated storage to ship orders in minutes to hours, enabling same-day or even same-hour delivery in tight city grids.

- Each hub stocks 8,000–15,000 SKUs near urban shoppers, cuts delivery van miles by up to 30%, and swaps big trucks for e-bikes and electric vans to ease congestion.

- Electric fleets and optimized routes trim carbon emissions by up to 60% on last-mile runs; Kroger’s 2023 micro-hub cut fuel use by 25% and packaging waste by 15%.

- Companies slash per-order delivery costs by as much as 75%, invest $500K–$1M per micro-hub, and use AI-driven demand forecasts to cut inventory waste and speed order fulfillment.

- Shoppers enjoy real-time tracking, hyper-local assortments by ZIP code, and options like curbside pickup; over half of buyers aged 18–34 now expect same-day service.

Faster and More Efficient Deliveries

Micro-hubs boost last-mile delivery speed with smart sensors and robotic arms, cutting wait times. Shoppers get packages in hours, not days.

Reduced delivery times in urban areas

Orders zip off from micro-fulfillment centers in minutes to hours, fueling same-day or even same-hour delivery in tight city grids. These centers use automated storage and retrieval systems with IoT devices, to track stock in real time, and to power smart city supply chains.

Retail stores and online shops link with these hubs, cutting inventory management gaps and boosting operational efficiency.

Drivers hop into electric cycles or driverless vans, thanks to route optimization tools, to slash last-mile delivery times. Customers beam at lightning-fast delivery, and demand forecasting helps hit precise delivery windows, making customer satisfaction soar.

Optimized order processing and fulfillment

Micro-fulfillment centers pack orders in tight urban blocks. No more playing hide-and-seek with stock. They use automated storage and retrieval systems (AS/RS) with conveyor robots and robotic shuttles to grab items in seconds, shaving minutes off picking cycles.

A warehouse management system (WMS) talks to IoT sensors, streaming real-time inventory tracking data, so staff skip fruitless shelf hunts. This tech blend drives same-day deliveries and trims last-mile mileage.

Demand forecasting software, powered by artificial intelligence, analyzes online shopping spikes, shaping pick-and-pack shifts. Micro hubs sit steps from customer doors, so micro distribution centers shrink, and delivery vans log fewer miles.

Urban logistics gain higher operational efficiency and cut carbon emissions when e-bikes or electric vans replace big trucks. Customer satisfaction soars as online orders hit doorsteps faster with next-day or same-day delivery.

Reduced Traffic Congestion

City hubs cut miles on busy roads, so large vehicles park and streets breathe. IoT sensors and route maps guide delivery vehicles and bikes, like a conductor leading a show.

Decentralized hubs minimizing delivery vehicle usage

Micro-fulfillment centers sit near urban shoppers. Each hub holds 8,000 to 15,000 SKUs. A warehouse management system runs on IoT sensors for real-time inventory tracking and fast order picking.

The design cuts last-mile delivery costs in e-commerce logistics and slashes supply chain delays. It slashes delivery vehicle miles.

Local hubs let couriers shift to electric vans and cargo bikes on short runs. Automated storage and retrieval systems speed up order sorting. Online orders go out within hours, with same-day delivery in some areas.

Traffic falls, carbon emissions shrink, and urban logistics get smoother.

Improved urban traffic flow with fewer large trucks

Streets breathe easier as local hubs send out nimble vans instead of large rigs. Micro-fulfillment centers use warehouse bots and smart sensors to plan runs. Shorter routes trim fuel use and costs by up to 30%.

Vans slip through side streets, cutting traffic congestion and carbon emissions.

AI algorithms guide last-mile delivery teams for same-day delivery with speed. This shift boosts operational efficiency and cuts gridlock. City residents spot clearer roads and fewer noisy big trucks.

Lower Carbon Emissions and Sustainability

Fleets of electric vehicles slash carbon footprints in tight city grids. Connected sensors and warehouse software help teams spot waste and curb emissions fast.

Eco-friendly last-mile delivery solutions

Cities gain green routes around micro-fulfillment hubs that cut last-mile delivery runs by up to 30%. They cut fuel use by 20% and curb carbon emissions. Kroger’s hub in 2023 cut gas use by 25%.

Automated packing machines scan orders with IoT sensors. These tools reduce packaging waste by 15%. They live inside stacker cranes.

Electric bikes and small vans zip along narrow lanes, so trucks stay off busy streets. Self-driving cars and unmanned quadcopters run on batteries and solar panels. They slash noise and air pollution in dense zones.

This short-haul fleet cuts the carbon footprint and boosts customer satisfaction.

Integration of electric and autonomous vehicles

Electric vans power micro-fulfillment fleets. They cut carbon emissions by up to 60% in urban runs. Smart charging stations route energy off peak, trimming grid strain. Robotic racks feed vans fast, for same-day delivery.

An inventory platform syncs stock with each shipment.

Autonomous shuttles follow optimized routes all day. They drop parcels within tight urban streets, easing traffic jams. A machine learning model predicts demand, guiding driverless vans smoothly.

Cost Savings for Businesses

Micro-hubs shave big chunks off delivery and warehousing bills with robotic pickers and a WMS fueled by IoT sensors. They slice costs like a chef chopping veggies, while AI demand forecasts stop extra stock from hogging your cash.

Reduced transportation and warehousing costs

Small urban depots cut real estate and labor costs. They shrink giant warehouses into pint-size hubs. This change slashes delivery costs per order by up to 75%. AI tools and a WMS grab items with mechanical pickers fast.

They link stock to a sensor network for real time inventory management. These hubs ease e-commerce logistics and curb truck runs. That cuts fuel bills and carbon emissions. The move boosts last-mile delivery and trims supply chain waste.

Improved operational efficiency for logistics providers

Micro-fulfillment hubs boost operational efficiency for logistics teams. Providers process orders in minutes or hours with AS/RS and a smart WMS. An AI system tracks inventory in real time.

A modular layout lets teams add racks or bots in a snap. Workers load items within feet of vans for same-day, last-mile delivery. AI tools match stock to demand across city zones.

Enhanced Customer Experience

AS/RS robots, AI, and smart IoT sensors in micro-fulfillment hubs pack orders fast, like your own butler. Then an e-bike courier zips across town, sending real-time tracking updates from WMS dashboards, so your same-day groceries show up fresh, and right on time.

Faster delivery times and real-time tracking

Micro hubs speed up last mile delivery. They sit close to buyers in city centers. Staff pick items from shelves in minutes. The system links smart sensors and warehouse management software for real time inventory tracking.

Firms grab this edge to offer same-day delivery. More than half of shoppers aged 18-34 expect this service. AI picks the best route using map data. Apps show drop off paths and live updates.

This boosts customer satisfaction and cuts support calls.

Personalized and hyper-localized services

Vendors deploy smart sensors and AI for real-time inventory tracking. This platform syncs stock across shelves, curbside lockers, and websites. Shoppers grab items in store, at the curb, or get same-day delivery with a click.

Drivers follow route optimization to speed last-mile delivery through busy streets. That local focus, backed by automated storage and retrieval systems and warehouse management integration, raises customer satisfaction and cuts wasted trips.

Neighborhood hubs sit within a mile of most buyers to offer hyper-localized services. Chains tailor assortments by ZIP code and local demand forecasting models. Customers love fast delivery, real-time tracking, and precise availability.

Support for in-store, curbside pickup, and online orders boosts convenience. Brands see richer customer satisfaction scores as they deliver local hits.

Emerging Technologies Driving Micro-Fulfillment

AI-driven robots link with connected sensors and refill shelves in seconds. Warehouse software tracks units and triggers automated lifts to pick orders in under a minute.

Robotics and automation in urban hubs

Micro-fulfillment centers use robotic picking systems and automated storage and retrieval systems. They boost order flow, tighten inventory management, and slash pick times by 50 percent.

A warehouse management system (WMS) taps artificial intelligence, and computer vision to track items in real time, and to guide bots to the right shelf. Urban shoppers enjoy faster same-day delivery from this efficiency boost.

Internet of things sensors track stock levels, alerting teams to refill shelves before items vanish. Tiny, self-driving carts and electric vans whisk out orders on crowded streets, trimming delivery trucks, and cutting carbon emissions.

AI-powered inventory management systems

A smart algorithm taps machine learning to forecast demand. It scans past orders from warehouse management systems. IoT sensors feed live data and real-time inventory tracking informs restock alerts.

City hubs use these insights to hit same-day delivery targets. They cut waste and idle stock fast.

Active AI links to automated storage and retrieval systems. It moves items before customers click check out. This blend of AI, WMS, and Internet of things delivers razor-sharp order accuracy and boosts operational efficiency.

Shoppers get products on time, and logistics teams spot trends in minutes.

Challenges in Implementing Micro-Fulfillment Centers

Planners fight for small sites, and they fit in AI, networked sensors, automated racks, and warehouse platforms on tight budgets. They juggle zoning rules, tech costs, and supply chain flows.

Urban real estate constraints

Tight footprints and sky-high rents squeeze urban micro-fulfillment hubs. Annual rent often climbs past thirty dollars per square foot in downtown districts. This limited space drives clever layout designs and stacked racks to keep up with e-commerce logistics and last-mile delivery demands.

Logistics teams adopt robotic bins and smart inventory platforms to boost operational efficiency. They tap into IoT sensors and AI alerts to track stock in real time. Shorter pick paths cut travel time for couriers, trimming supply chain costs and carbon emissions.

High initial setup costs and technology integration

Micro-fulfillment centers carry high setup price tags. They need robotics and automated storage and retrieval systems. They also need AI tools and warehouse management systems tied to IoT sensors.

Grocers face bills from $500,000 to $1 million per hub. That tech can speed order picking and shave delivery times. Operators hope it boosts operational efficiency in urban logistics.

Cyberattacks and power outages can halt last-mile delivery. Managers hire IT teams to guard systems and run real-time inventory management. Ongoing upkeep can add 15 percent to annual costs.

Tight funds may slow network expansion in packed cities.

Takeaway

Small hubs cut delivery times and improve urban logistics. They use automated storage and retrieval (AS/RS) and AI to boost picking and operational efficiency. Shoppers cheer faster last-mile delivery and better tracking.

Logistics teams trace stock with WMS, for sharper inventory management. Cities enjoy lower carbon emissions and greener streets thanks to electric trucks.

FAQs on Impacts of Micro-Fulfillment Centers on City Logistics

1. What are micro-fulfillment centers and how do they change urban logistics?

They are small warehouses in urban areas, they store goods close to shoppers. They speed up last-mile delivery, same-day delivery and next-day delivery. They use warehouse management systems, robotics and modular design to handle online orders in tight retail space.

2. How do micro-fulfillment centers make delivery faster?

They use real-time inventory tracking, demand forecasting and route optimization. They pack orders like a pro Tetris player, they send parcels via cyclists, vans or drone delivery. They cut delivery times, calm traffic congestion and boost delivery efficiency.

3. What technology powers these small hubs?

They mix artificial intelligence, the internet of things and automated systems. They run automated storage and retrieval systems, they use advanced robotics, they link sensors and software. They talk to suppliers and logistics service providers, they log data for food delivery or pharmacies.

4. How do micro-fulfillment centers help the environment?

They cut carbon emissions and shrink the carbon footprint. They lower energy consumption in compact spaces, they follow green building tips. They use sustainable transport like bike runs and unmanned aerial vehicles, they fit right into smart cities and sustainable city plans.

5. Do these centers boost customer satisfaction?

Yes, they meet consumer expectations for fast delivery and in-store pickup. They stock over-the-counter items at pharmacy chains, they power smooth e-commerce logistics. They let shoppers grab orders in minutes, they curb long checkout waits.

6. Are micro-fulfillment centers ready to scale up?

Yes, they use scalable, modular design to grow with demand. They slot into the supply chain quickly, they adapt with change management tools and augmented reality tests. They plug into local transit hubs or store backrooms, they flex with new consumer behaviors.