Many online retailers face slow shipping and high labor costs. They juggle warehouses, fulfillment centers, and inventory management. More than half of online stores use third-party logistics to speed up shipping.

In this post, we cover seven fulfillment models every e-commerce brand should know. We explain self-fulfillment, third-party logistics, dropshipping, Fulfillment by Amazon, hybrid options, crowdsourced models, and subscription box services.

You will learn pricing tips, packaging hacks, and how to link your ecommerce platform with top delivery services, like walmart and amazon prime. You will see how to smooth your supply chain and cut transport fees.

Ready to pick your model?

Key Takeaways

- More than half of online stores use third-party logistics to speed shipping and lower labor costs.

- Self-fulfillment works for brands with under five daily orders but leaves sellers handling $248 billion in US returns in 2023.

- Dropshipping cuts inventory risk by letting suppliers ship directly in 2–5 days on average across North America.

- Amazon FBA uses distribution hubs near buyers, serves Prime members fast, and charges per package size and weight.

- Hybrid, crowdsourced, and subscription models flex to demand, cut up to 20 percent in storage fees, and boost customer loyalty.

Self-Fulfillment

Self-fulfillment means a company grabs each order and ships it straight from its own storage space. Startups often pick this business model to stay lean and in control. Staff print labels, pack items, then send parcels with a carrier.

Small teams handle warehousing, track stock in an order management system, and tweak version updates on the site. The brand can offer same-day delivery in local zones. Returns pile up fast, though; U.S. shoppers sent back nearly $248 billion in goods in 2023, and every return goes right onto the seller’s desk.

Businesses that see fewer than five orders a day may not find value in outsourcing. They skip outside warehouse fees, keep inventory close, and chat face-to-face with shipping staff.

Handy tools like a scanner and a printer keep costs low. Folks master basic logistical work, sort stock by code, and pack orders faster. Big outfits like amazon’s network count on dozens of distribution centers, but a small brand can stick to its own garage for a while.

Third-Party Fulfillment

Third-party providers pack e-commerce orders fast, ship parcels to your customers. They tap bulk discounts, so your rates drop. You pay only for the space you use and the hours you need.

Fulfillment staff sorts, labels, and loads boxes. Shopify Fulfillment Network links your store to Flexport and other carriers. That network has no minimum stock requirement. Data moves between your store and SFN at no extra charge.

Brands with wild swings in demand gain quick help. Expert logistics teams steer your orders. Flexible pricing plans match slow weeks or peak seasons. Firms with no big warehouses can join too.

Costs stay lean while sales climb.

Dropshipping Fulfillment

This model leaves the heavy lifting to manufacturers. No packing peanuts clutter your office. They ship products straight to buyers without you touching a box. Shop owners use Oberlo inside Shopify to link products from an online marketplace or suppliers.

Order processing moves along the supply chain, while you track shipments in real time.

Small brands cut down upfront costs since they hold no stock. Fulfillment handled by a wholesale partner or a fulfillment service reduces risk. Experts say manufacturers ship directly to buyers in 2 to 5 days on average across North America.

This common eCommerce setup keeps margins tight and overhead low.

Fulfillment by Amazon (FBA)

Amazon FBA moves your products to distribution hubs near major centers. It cuts your work on packing, storing, and shipping. Millions of Prime members gain fast delivery. You tap into Amazon’s massive B2C and C2C market across dozens of categories.

It feels like a warehouse genie for busy sellers. You load your items via the seller dashboard and print mail tags with a click. Stock tracking tools show real-time on-hand levels.

Fees depend on each package’s size and weight, and you pay only for what you store and ship.

Hybrid Fulfillment Models

A hybrid approach blends self-fulfillment, third-party services, and dropshipping for certain SKUs. This mix helps brands adapt. It rolls orders through an e-tail platform like Shopify, and a shipping platform connects via API Integration to an Inventory Management System.

Third-party warehouses handle oversize inventories, while staff pack daily essentials in-house. You cut costs on slow movers, ship special items direct from a supplier. You get speed and scale, without extra overhead.

Firms split orders based on demand, use Demand Forecasting to flag busy seasons like holiday sales 2023. A small batch of custom tees ships from current stock, while bulk orders flow through a courier service such as UPS or FedEx.

Order Management Software tracks each step, sends alerts if stock dips below threshold. Many brands save 20 percent on storage fees with this system. I once saw a small label tackle a flash sale, they stayed calm and smiled amid the rush.

Crowdsourced Fulfillment

Crowdsourcing taps local helpers who pick, pack, and ship orders through a neighborhood network. Warehouses hand off parcels to independent contractors. The model uses a network of independent contractors.

It scales fast when holiday surges hit, and shrinks on slow days. It can reduce delivery times, since drivers live nearby. It stays popular with gig economy platforms.

GPS tracking and delivery dispatch software link each courier to a central hub. Brands tap smartphone apps and API integration to route orders. Many platforms resemble ride sharing or food delivery apps, where drivers log pickups in real time.

It feels like waving a magic wand, and an order drops on your porch. Couriers chat with a single tap, they solve hiccups fast. This flexible approach lets brands grow, without building new storage sites.

Subscription Box Fulfillment

Subscription box services rely on recurring payments to fund each new cycle, customers gain perks. SaaS platforms like Subbly or Recharge handle billing and signups with ease. Inventory systems sync levels and alert staff before stock drops.

CRM profiles guide item picks, they use past buys to tweak each package.

You pair ShipStation or ShipBob with your ERP module to speed shipments. APIs move data fast, they link orders, stock, invoices. Brands slip in a comic or sticker, they add a smile to the unboxing.

This workflow builds lasting bonds, your readers will stick around.

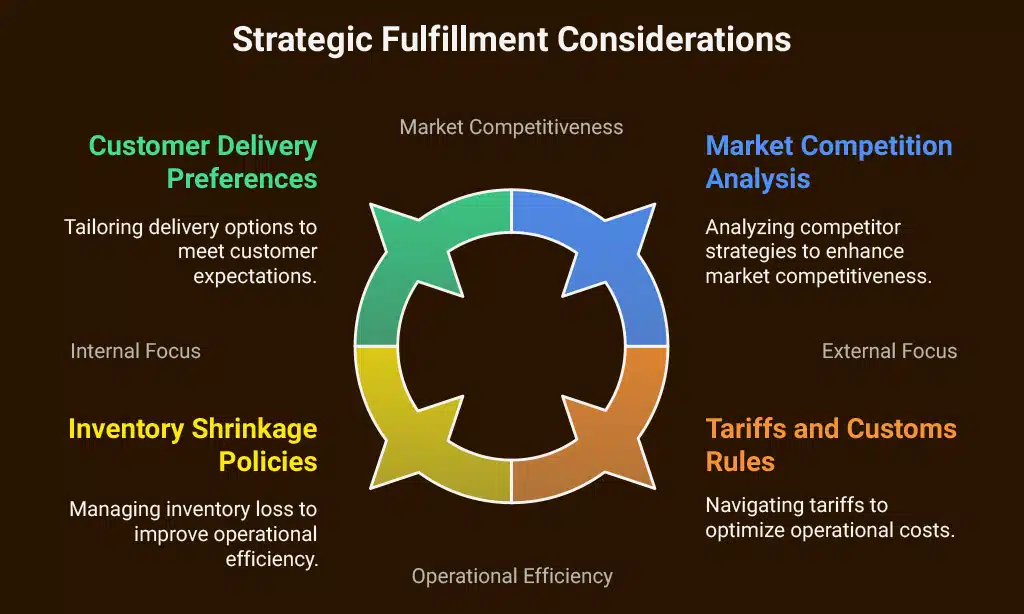

Key Considerations for Choosing a Fulfillment Model

Your brand faces many choices. Each one impacts your shipping costs.

- Tariffs and Customs Rules: You check duty rates in main markets and apply Incoterms to set payment terms, you watch fees that can erode margin.

- Data and Analytics Platforms: You use business intelligence tools and an enterprise resource planning system for clear KPIs, you spot trends before they squeeze profit.

- Fulfillment Center Geography: You map center locations to customer clusters, you cut delivery times and shipping miles.

- Inventory Shrinkage Policies: You review how partners handle loss and damage, you compare claim tiers and insurance fees.

- Customer Delivery Preferences: You poll buyers about speed and cost tradeoffs, you tweak options from same-day to economy to boost loyalty.

- Market Competition Analysis: You track rival shipping fees and perks, you match or beat local offers to stay ahead.

Takeaways

Picking the right fulfillment path feels like lacing the perfect shoe for a long race. Some brands run on self-pack, while others pass boxes to a 3PL partner. Amazon FBA brings speed, but crowdsourced pickers can add local flair.

Subscription kits ride a steady wave of repeat buyers. Dropship flows cut out extra stops. Mixing models can feel like cooking with bold spices. A clear vision and the right software, like an order manager or stock tracker, steer the ship.

Now, go pick your path and start the journey.

FAQs on Fulfillment Models for E-Commerce

1. What does a fulfillment model mean for an e-commerce brand?

A fulfillment model maps out how your online orders move from storage, to packing, to shipping, to your customer’s doorstep.

2. Why study the seven fulfillment models?

Each model offers a different mix of cost, speed, and control. Learning all seven helps you pick the best path as your brand grows, like choosing the right tool for the job.

3. How do I choose between self-handled and outsourced order flow?

Think of it like a test drive. List your budget, order volume, and team skills. Then match those needs to the model that fits your brand’s goals.

4. Can I mix different delivery strategies?

Yes, many brands keep some stock in-house, and send other items to external centers. It’s like a buffet—you fill your plate with what works best.