Industrial sewing machines are vital in the manufacturing process of numerous products, including mattresses, furniture, car seats, and clothing. These powerful machines are designed to handle the heavy-duty demands of mass production, offering durability, precision, and speed far beyond the capabilities of domestic sewing machines. In this article, we will explore how industrial sewing machines supplied by companies such as Atlantic Automation Co. contribute to various industries, examine different machine types, and highlight the attachments that enable specific tasks.

Industrial Sewing Machines in Different Industries

1. Mattress Manufacturing

Mattress production requires strong, precise sewing machines capable of stitching through multiple layers of thick materials, such as foam, fabric, and quilting. Heavy-duty lockstitch and chainstitch machines are commonly used to assemble mattress covers, sew binding along the edges, and apply decorative stitching to quilted surfaces. Specialized machines like tape-edge sewing machines are designed to stitch the borders of mattresses securely, ensuring durability and a professional finish.

2. Furniture Production

The furniture industry depends on industrial sewing machines to craft upholstery for sofas, chairs, and other furniture pieces. These machines handle various materials, including leather, vinyl, and heavy fabrics. Walking foot machines, also known as compound feed machines, are essential in this sector. They prevent material slippage and ensure even stitching by moving both the fabric’s top and bottom layers simultaneously. In addition, programmable sewing machines can automate complex patterns, saving time and ensuring consistency in large-scale production.

3. Automotive Interiors (Car Seats)

Automotive interiors require precision and durability, especially for car seats, where safety and aesthetics are key factors. Industrial sewing machines designed for automotive applications often feature high-speed, programmable operations to handle leather and reinforced fabrics. Double-needle machines are commonly employed to create parallel seams, which are both visually appealing and structurally strong. Additionally, bar-tacking machines are used to reinforce stress points, such as seatbelt openings and other high-tension areas.

4. Clothing Manufacturing

In the fashion industry, efficiency and versatility are critical. Industrial sewing machines streamline the production of garments by performing a variety of tasks, including seaming, hemming, and buttonholing. Overlock (or serger) machines are essential for finishing fabric edges to prevent fraying, while coverstitch machines create professional hems on stretchy fabrics. Many factories utilize automatic sewing machines that can cut and sew fabric in a single operation, significantly speeding up production times.

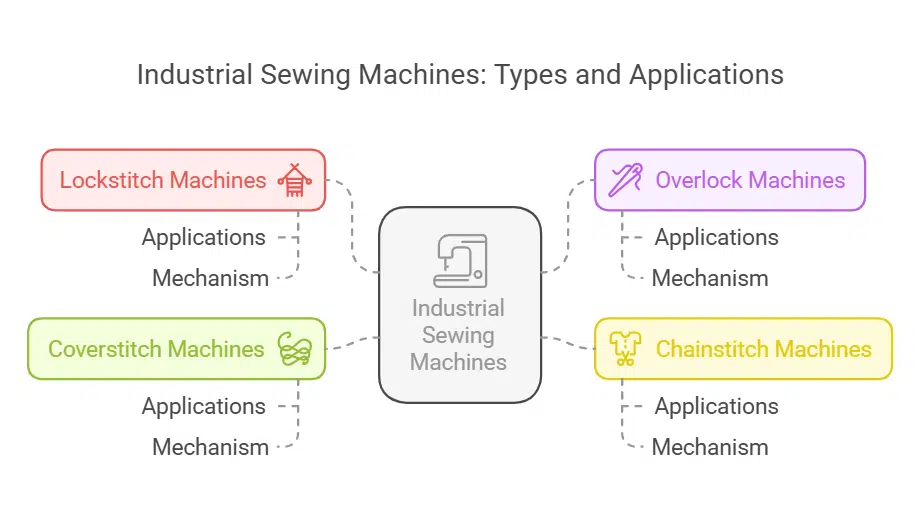

Types of Industrial Sewing Machines

Industrial sewing machines are categorized based on their stitching mechanism and application. Here are some common types:

- Lockstitch Machines

- These machines use a needle and a bobbin to create a tight, secure stitch. They are versatile and widely used for sewing straight seams on various materials.

- Chainstitch Machines

- Instead of a bobbin, these machines use a looper to create a continuous chain of stitches. They are ideal for tasks requiring flexibility, such as sewing elastic or decorative elements.

- Overlock (Serger) Machines

- Overlock machines trim fabric edges and simultaneously sew over the edge to prevent fraying. They are common in garment manufacturing for seam finishing.

- Walking Foot Machines

- Designed to handle thick and slippery materials, these machines use a walking foot mechanism to ensure even feeding of multiple fabric layers.

- Programmable and Automatic Machines

- These machines are equipped with digital controls that allow operators to program complex stitching patterns. They improve efficiency and consistency in large-scale production.

Essential Attachments for Industrial Sewing Machines

Attachments enhance the functionality of industrial sewing machines, enabling them to perform specialized tasks efficiently. Here are some commonly used attachments:

- Presser Feet

- Various types of presser feet are available for specific applications, such as zipper feet for inserting zippers, edge guides for straight seams, and roller feet for sewing leather or vinyl.

- Binders

- Binders guide and fold binding tape around fabric edges, creating a clean and durable finish. This attachment is particularly useful in mattress and automotive seat manufacturing.

- Seam Guides

- Seam guides help maintain consistent seam allowances, improving accuracy and reducing production errors.

- Buttonhole and Button Attachments

- These attachments automate the creation of buttonholes and the sewing of buttons, speeding up garment production.

- Needles and Feed Dogs

- Specialized needles and feed dogs can handle various materials and stitching requirements. For example, leather needles have a wedge-shaped point to penetrate tough materials without damaging them.

Conclusion

Industrial sewing machines play a crucial role in the efficient manufacturing of mattresses, furniture, car seats, and clothing. Their durability, speed, and precision make them indispensable in mass production. By utilizing various machine types and specialized attachments, manufacturers can achieve high-quality results tailored to the unique demands of their industries. As technology advances, the continued innovation of industrial sewing machines promises even greater productivity and customization capabilities in the future.