The 3PL industry is changing fast. Many companies struggle to keep up with rising costs, labor shortages, and new technology. If your logistics feel outdated or too expensive, you’re not alone.

Disruptive business models are redefining third-party logistics right now. Startups use digital tools, automation, and AI to cut costs and boost efficiency. This blog breaks down the top 7 game-changing ideas shaking up the industry.

Learn how they work—and why they matter for your supply chain. Read on to stay ahead of the curve.

Innovating On-Demand Warehousing

Need extra space fast? On-demand warehousing lets businesses rent storage by-the-hour without long contracts or big costs.

Startups are shaking things up with smart tech that matches free warehouse space with companies who need quick storage solutions—no strings attached!

Exploring On-Demand Warehousing

On-demand warehousing is shaking up traditional 3PL models by offering flexible storage solutions. Startups are leading the charge, using digital platforms to connect businesses with unused warehouse space instantly.

This cuts costs, boosts efficiency, and adapts quickly to changing demand.

Rising transport and energy costs make fixed warehouses a burden for many companies. On-demand options give them room to scale without long leases or empty space. AI helps match needs with available storage, making it smarter than ever.

The trend toward non-asset-based models proves customers want agility over ownership.

Advantages of On-Demand Warehousing

On-demand warehousing is changing how businesses handle inventory. It offers flexibility, cost savings, and faster operations.

- Lower Costs: Companies avoid long-term lease commitments. They pay only for the space they use, cutting overhead expenses.

- Scalability: Businesses can quickly adjust storage space as demand changes. This helps during peak seasons or unexpected growth.

- Faster Market Entry: New locations can be secured without delays. This speeds up distribution, especially for ecommerce brands.

- Reduced Risk: No need to own or lease large warehouses. Startups and small firms can compete without heavy investments.

- Eco-Friendly: Shared warehouse space leads to fewer empty facilities. This supports sustainable logistics by reducing waste.

- Tech-Driven: Digital platforms match businesses with available space. AI helps optimize inventory management and reduce errors.

- Global Reach: On-demand networks provide access to warehouses worldwide. This simplifies international supply chain management.

Rising transport costs and labor shortages make this model even more attractive. Startups are using it to disrupt traditional 3PL operations.

Startup Innovations in On-Demand Warehousing

Startups are shaking up the logistics world with fresh ideas in on-demand warehousing. They use tech to solve old problems and meet new demands.

- Flexible space solutions: New platforms let businesses rent warehouse space by the hour or day, cutting long-term lease costs.

- AI-driven pricing: Smart algorithms adjust rates based on demand, location, and season, making storage cheaper when you need it.

- Real-time tracking: Startups offer apps that show inventory levels and storage conditions instantly, from anywhere.

- Pop-up warehouses: Temporary storage hubs pop up near high-demand areas, cutting shipping times and costs.

- Automated matching: Digital platforms connect companies with extra space to those who need it, like an Airbnb for warehouses.

- Green storage options: Some startups focus on solar-powered or energy-efficient facilities, appealing to eco-conscious brands.

- Robotic assistance: Small bots handle sorting and moving goods in shared spaces, speeding up operations without big investments.

Revolutionary Digital Platforms in Third-Party Logistics

Digital platforms are changing how third-party logistics work by making operations faster and smarter through real-time tracking tools that boost efficiency like never before! With AI-driven insights helping businesses predict demand better than old-school methods could dream possible—these tech upgrades aren’t just nice-to-haves anymore but game-changers reshaping entire supply chains overnight!

Features of Innovative Digital Platforms

The 3PL industry is changing fast, thanks to digital platforms. These tools make logistics smoother and smarter.

- AI and machine learning help predict delays and optimize routes. Companies use these to cut costs and improve delivery times.

- Real-time tracking lets businesses see where shipments are at all times. This boosts transparency and builds trust with customers.

- Automated inventory management reduces human errors. It keeps stock levels accurate and saves time.

- Data analytics spots trends in shipping and demand. Firms use this to plan better and avoid shortages.

- Cloud-based systems allow easy access from anywhere. Teams can work together without being in the same place.

- Blockchain technology makes transactions secure and transparent. It helps prevent fraud in freight forwarding.

- Integration with e-commerce speeds up order processing. Sellers connect directly with logistics providers for faster shipping.

- Collaborative freight models match shippers with spare truck space. This cuts empty miles and lowers emissions.

- Last-mile delivery solutions focus on faster, cheaper urban shipping. Drones and smart lockers are becoming popular options.

- Custom reporting tools give clear insights into performance. Businesses track KPIs to stay ahead of the competition.

AI and Machine Learning Enhancements in 3PL

AI and machine learning are changing how third-party logistics (3PL) works. These tools help predict delays, optimize routes, and cut costs. Startups use AI-powered digital platforms to streamline operations, making freight forwarding faster and smarter.

Predictive analytics spot risks before they happen, improving contract management and cybersecurity.

Warehouse robots now sort packages with precision, reducing human errors. Machine learning also improves inventory management by forecasting demand accurately. Rising transport costs push 3PL firms to adopt AI for fuel-efficient routes.

Automation handles repetitive tasks, freeing workers for complex jobs while tackling labor shortages in the industry.

Advances in the Sharing Economy for Logistics

Truck space is now shared like a ride-share app, cutting costs and waste. Companies like Convoy are making empty miles a thing of the past.

Rise of Collaborative Freight Models

The sharing economy has hit freight logistics hard—companies now pool resources like trucks or warehouse space through digital platforms instead going solo on costly assets.Startups lead this shift,matching spare capacity across fleets,increasing efficiency,and cutting empty miles.This approach tackles rising transport costs head-on while helping smaller players compete globally.Collaborative models thrive because tech makes coordination easy,and customers prefer flexible solutions over owning expensive infrastructure.Some firms already slash expenses by upselling unused storage or backhaul trips,turning waste into profit without heavy investments.AI-driven matching tools take guesswork out too,pairing shipments faster than old-school brokers could dream.That’s why investors back these nimble newcomers reshaping traditional freight forwarding one shared load at a time.Labor shortages push more shippers toward such partnerships as well,since scaling up internally gets tougher each year.The trend won’t slow down anytime soon,either.Digitalization lets everyone win here—carriers fill seats,businesses save cash,and sustainability gets an accidental boost along route optimization paths nobody planned alone before now!

Success Stories in 3PL Sharing Economy

The sharing economy is shaking up third-party logistics (3PL). Companies are finding new ways to cut costs and boost efficiency through collaboration.

- Flexe leads in on-demand warehousing by connecting businesses with unused storage space. Their digital platform helps companies scale up or down fast without long-term leases.

- Convoy uses a freight-sharing model to match truckers with shipments. This reduces empty miles and saves shippers up to 20% on transport costs.

- Cargomatic acts like Uber for local freight. Their app links shippers with nearby carriers to fill unused truck space quickly.

- Flock Freight pools shipments from multiple customers into one truckload. This shared-truck approach cuts emissions and lowers prices for small businesses.

- Loadsmart applies AI to automate freight matching. Their system finds shared loads faster than traditional brokers while improving pricing transparency.

- Zencargo helps brands share container space on ocean freight routes. This slashes costs for small importers who can’t fill whole containers alone.

- ShipBob offers shared fulfillment centers for ecommerce sellers. Their network lets stores split warehouse costs while reaching customers faster through distributed inventory.

Startups like these prove collaboration beats going solo in logistics today. Shared assets mean lower overheads for everyone involved while keeping goods moving smoothly worldwide without breaking budgets or harming our planet unnecessarily either way you slice it really!

Green Approaches in 3PL Business Models

More 3PL firms are cutting carbon footprints with electric fleets and solar-powered warehouses. Eco-friendly logistics isn’t just a trend—it’s saving money and winning customers.

The smartest players use recycled packaging and route optimization to slash waste. Green 3PL isn’t charity; it’s smart business with a cleaner future.

Adopting Green Logistics

Green logistics is no longer optional. Companies are cutting carbon footprints by using eco-friendly transport, energy-efficient warehouses, and smarter routes. Rising fuel costs push 3PL firms to adopt electric vehicles and renewable energy, saving money while meeting customer demands for sustainability.

Startups lead the charge with digital tools that track emissions and optimize supply chains for minimal environmental impact.

Eco-conscious 3PL providers stand out by offering recycled packaging, waste reduction programs, and reverse logistics for returns. Political instability and global pressures make green practices a competitive edge.

Shippers now prefer partners who align with their sustainability goals, proving that going green isn’t just good for the planet—it’s smart business.

Spotlight on Eco-Friendly 3PL Companies

Eco-friendly 3PL companies are changing the game in sustainable logistics. They cut waste and boost efficiency while meeting rising demand for green solutions.

- Flexe offers on-demand warehousing, reducing empty space and energy use. Their digital platform matches businesses with spare storage, slashing carbon footprints.

- ShipBob uses data analytics to optimize shipping routes. This cuts fuel consumption and speeds up last-mile delivery for ecommerce brands.

- DHL Green Logistics runs electric fleets and carbon-neutral warehouses. They aim for zero emissions by 2050, setting a high bar for the industry.

- Convey focuses on reverse logistics to reduce returns waste. Their tech helps retailers reuse or recycle products instead of trashing them.

- NEXT Trucking connects shippers with carriers using AI. This reduces empty truck trips, cutting freight forwarding emissions by up to 20%.

- Flexport tracks shipments with blockchain for full transparency. Clients see real-time carbon impacts and choose greener transport options.

- Ryder’s Eco-Rollouts include solar-powered warehouses. They also train staff in energy-saving practices, proving small changes add up fast.

Blockchain Innovation in Third-Party Logistics

Blockchain is shaking up 3PL by making supply chains more transparent and secure. Smart contracts cut out middlemen, speeding up payments and reducing errors.

Increasing Transparency with Blockchain

Blockchain technology brings unmatched clarity into third-party logistics (TPL). It tracks every step like an unbreakable digital ledger so everyone sees real-time updates without doubts or delays – perfect proof against fraud too!

AI-driven smart contracts speed things up automatically when conditions get met; payments release faster while cutting paperwork headaches down big time! Plus its tamper-proof records help meet tough rules smoothly across borders – making global trade simpler yet safer than before!

Practical Blockchain Applications in 3PL

Blockchain is changing how 3PL works, bringing more trust and efficiency. It tackles big problems like transparency and cost in logistics.

- Transparent tracking – Blockchain records every step of a shipment. This cuts fraud and errors in supply chain management.

- Smart contracts – These auto-process payments when delivery conditions are met. No delays, no paperwork headaches.

- Secure data sharing – Companies share info safely without middlemen. This speeds up freight forwarding and cuts delays.

- Fake goods prevention – Blockchain verifies product origins. E-commerce brands can stop counterfeit items fast.

- Faster customs clearance – Digital ledgers store shipping docs securely. No more lost papers or long waits at borders.

- Efficient inventory management – Real-time updates prevent stock issues. Warehouses know exactly what’s coming and going.

- Lower costs – Fewer errors mean less wasted time and money. Rising transport costs hit smaller shippers harder, but blockchain helps balance it.

- Better compliance – All actions are logged permanently. This makes audits simpler for green logistics and regulations.

Startups are already using blockchain for leaner, smarter 3PL services. It’s one reason digitalization is reshaping the logistics industry fast.

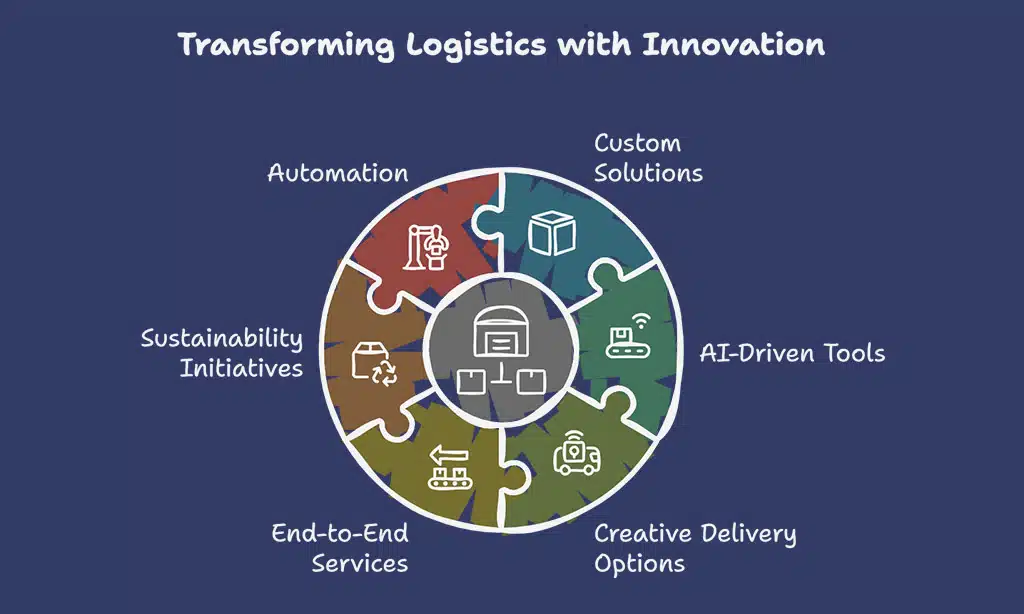

Enhancing 3PL with Value-Added Services

Businesses now expect more from 3PL providers than just storage and shipping—custom solutions like kitting, labeling, and returns management are in high demand. Companies that offer these extras stand out by turning logistics into a competitive edge for their clients.

Personalizing Logistics Solutions

Today’s 3PL providers know one-size-fits-all doesn’t work. Shippers want solutions customized to their needs, whether it’s fast ecommerce fulfillment or flexible inventory management.

Startups lead the charge with AI-driven tools that predict demand and optimize routes, cutting costs while keeping customers happy.

Custom logistics now includes creative last-mile options like locker pickups or crowd-sourced delivery. For example, some firms use data analytics to offer dynamic pricing for freight forwarding.

With labor shortages pushing companies toward 3PL partners, personalization isn’t just a preference—it’s essential for staying competitive in an industry moving rapidly toward digital supply chains and automation.

Creative End-to-End Delivery Services

End-to-end delivery services are changing 3PL for good. Companies now offer everything from warehouse storage to last-mile delivery in one seamless process. Startups use digital platforms and AI to track shipments, predict delays, and optimize routes.

This cuts costs and speeds things up while keeping customers happy with real-time updates.

Sustainability is also a big focus. Eco-friendly firms combine shared freight models with electric vehicles for greener logistics. Automation helps too—robots sort packages faster, reducing human error across the supply chain.

These innovations tackle key challenges like rising transport costs while meeting global demand without missing a beat.

Leveraging Automation and Robotics in Logistics

Robots zip through warehouses, picking and packing orders faster than humans ever could. Drones and self-driving trucks are no longer sci-fi—they’re slashing delivery times right now.

Trends in Warehouse Automation

Warehouse automation is changing how 3PLs operate. New tech is making logistics faster and cheaper.

- AI and Machine Learning – AI helps predict demand, manage inventory, and reduce errors. Machine learning improves routing and warehouse layouts.

- Robotic Picking Systems – Robots now handle repetitive tasks like picking and packing. This cuts labor costs and speeds up order fulfillment.

- Autonomous Mobile Robots (AMRs) – These robots move goods without human help. They adapt to warehouse layouts in real time.

- Automated Storage and Retrieval Systems (AS/RS) – Taller warehouses use AS/RS to store and fetch items quickly. It saves space and reduces manual work.

- IoT-Enabled Tracking – Sensors track inventory in real time. This prevents stockouts and lost shipments.

- Drones for Inventory Checks – Drones scan barcodes and monitor stock levels. They cut inspection time from hours to minutes.

- Voice-Directed Workflows – Workers get instructions via headsets, keeping hands free. This boosts accuracy and efficiency.

- Green Automation – Energy-efficient robots and solar-powered warehouses lower carbon footprints. Eco-friendly tech is a growing focus.

- Cloud-Based Warehouse Management – Real-time data syncs across locations. This improves coordination and reduces delays.

- Collaborative Robots (Cobots) – Cobots work alongside humans safely. They handle heavy lifting, reducing injuries.

Rising transport costs push 3PLs to automate more. Startups are leading the charge with smart digital platforms. The shift to non-asset models also fuels automation growth.

Robotics Integration in Distribution Operations

Robotics is transforming distribution operations, making warehouses faster and more efficient. Automated guided vehicles (AGVs) and robotic arms now handle picking, packing, and sorting with precision.

These systems cut labor costs while speeding up order fulfillment. Companies like Amazon use robotics to manage massive inventories without delays.

AI-powered robots adapt to demand spikes, a game-changer for e-commerce logistics. They reduce errors in inventory management and optimize storage space. With rising transport costs, automation helps 3PL providers stay competitive.

The shift toward non-asset-based models also favors tech-driven solutions over traditional manual processes. Robotics isn’t just the future—it’s reshaping logistics today.

Overcoming Challenges in Traditional Third-Party Logistics

Traditional 3PL firms must adapt fast or risk falling behind as new tech reshapes logistics. Many are now blending automation and data tools to stay competitive, but change isn’t always smooth sailing.

Adjusting to Innovative Business Models

The 3PL industry is changing fast, and old ways won’t cut it anymore. Companies must adapt or risk falling behind.

- Shift to Non-Asset Models: Customers and investors prefer lighter, tech-driven logistics firms. This move reduces costs and boosts flexibility in supply chain management.

- Adopt Digital Platforms: Startups are using AI and data analytics to streamline freight forwarding and inventory management. It’s no longer optional.

- Tackle Labor Shortages: Many 3PLs now partner with firms to offset talent gaps. Automation helps, but skilled workers still matter.

- Handle Rising Costs: Energy and transport prices are climbing. Smart route optimization and green logistics can soften the blow.

- Embrace Global Pressures: Expansion means dealing with trade rules and currency shifts. Digital tools help manage cross-border risks.

- Integrate Automation: Robots and AI speed up warehouse operations. From sorting to last-mile delivery, tech saves time and money.

- Prioritize Sustainability: Eco-friendly logistics attract clients and cut waste. Think electric fleets, reusable packaging, and carbon-neutral shipping.

- Leverage Blockchain: Transparent tracking builds trust in e-commerce and reverse logistics. No more guessing where shipments are.

- Offer Value-Added Services: Custom packaging, real-time updates, and white-glove delivery keep clients happy in a competitive market.

Competitive Strategies for Traditional 3PL Firms

Traditional 3PL firms must adapt fast to stay ahead. One smart move is embracing digital platforms to streamline processes, cut costs, and boost efficiency. Startups are already doing this well, forcing older players to keep up or fall behind.

Another key strategy is focusing on talent retention while tackling rising transport and energy costs. Many shippers now rely on 3PL partners to fill labor gaps. Companies that invest in automation and AI for tasks like predictive analytics or inventory management will gain an edge over slower competitors.

It’s a race—adapt or lose out.

Takeaways

The 3PL industry is changing fast, thanks to tech and smarter ways to move goods. From on-demand warehousing to AI-driven platforms, these new models cut costs and boost efficiency.

Want a greener supply chain or faster deliveries? These innovations make it possible. The future belongs to those who adapt—so why not start today? Explore these trends now, and stay ahead in the logistics game.