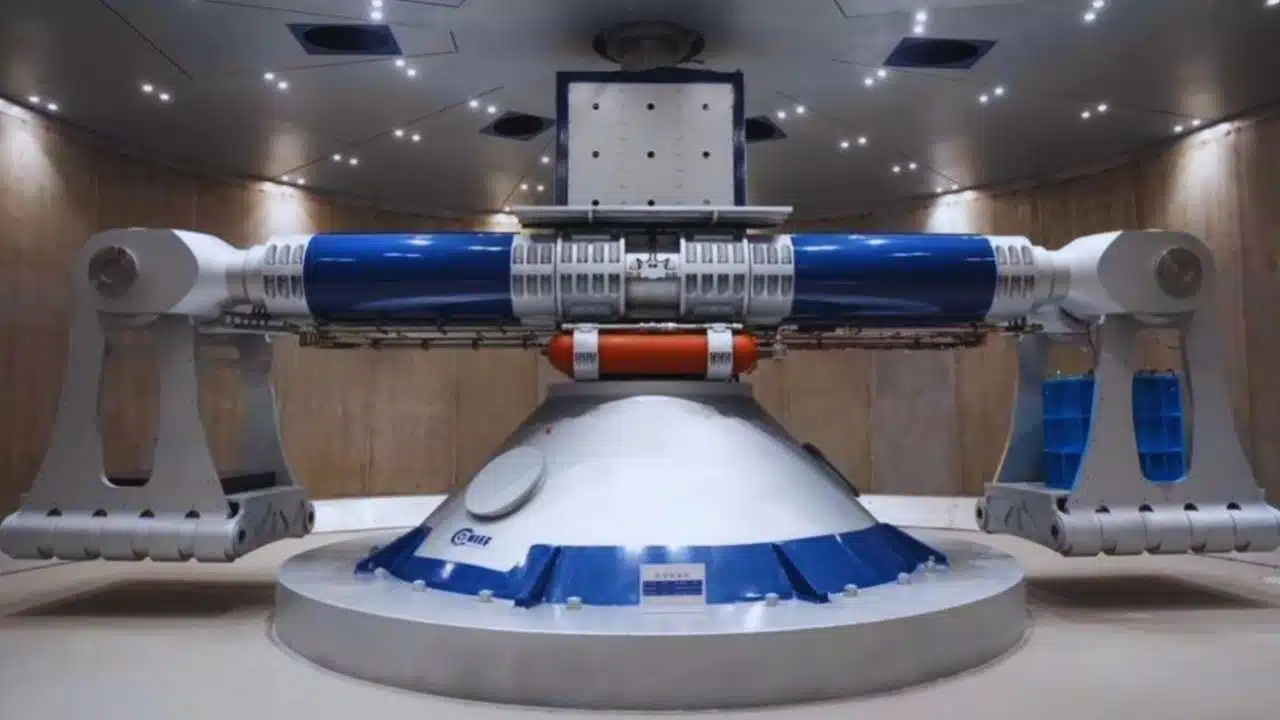

China is installing CHIEF1900, a next-generation hypergravity centrifuge that can create forces up to 1,900 times Earth’s gravity, at Zhejiang University’s underground CHIEF research complex in Hangzhou after delivery on December 22, as the country expands its large-scale experimental infrastructure for disaster, geology, energy, and materials research.

What China Installed and Where It’s Going

CHIEF1900 is a super-large hypergravity centrifuge developed by Shanghai Electric Nuclear Power Group and delivered to Zhejiang University for installation at the university’s Centrifugal Hypergravity and Interdisciplinary Experiment Facility (CHIEF) in Hangzhou, Zhejiang province.

The machine is being installed in an underground research hall roughly 15 meters below ground level—an engineering choice aimed at reducing vibration and improving experimental stability. The facility is designed to serve as a shared platform for universities, research institutes, and industry users, including international collaborators.

CHIEF1900 is expected to become the world’s most powerful centrifuge for scientific research by “capacity,” a metric typically expressed in g·tonne (g·t)—the product of centrifugal acceleration (in g) and payload mass (in tonnes). A higher g·t rating generally means a lab can apply higher forces to heavier test models, enabling more realistic simulations at meaningful scales.

Why CHIEF1900 Matters

Hypergravity centrifuges are often described as “time-and-scale compressors” because they let researchers reproduce, within minutes or hours, physical effects that might take years in nature or require massive real-world prototypes.

A common example used to explain the concept is dam safety testing:

- A 3-meter model of a dam, spun at 100g, can reproduce the stress conditions of a 300-meter real-world structure.

- This approach allows engineers to observe deformation, cracking patterns, seepage behavior, slope instability, and cascading failure pathways under controlled, instrumented conditions.

That ability matters for a wide range of high-stakes fields:

- Disaster mitigation: earthquakes, landslides, dam failures, levee instability, coastal hazards

- Deep-Earth and deep-ocean engineering: seabed infrastructure, deep resource extraction, high-pressure geotechnics

- Environmental protection: underground waste disposal, long-term pollutant migration through soils and rock

- Materials science: accelerated processing and testing in extreme-force environments

How CHIEF1900 Works in Plain Terms

A hypergravity centrifuge creates extreme effective gravity by spinning a long arm at high speed. Test samples sit inside specialized experiment “cabins” or payload modules at the end of the arm. When the machine spins, centrifugal acceleration increases dramatically, making the sample behave as if gravity were hundreds or thousands of times stronger than normal.

This enables two key experimental advantages:

- Scaling realism: Small physical models can behave like much larger structures because the body forces scale up.

- Accelerated processes: Flow, settling, consolidation, and mechanical responses can be sped up, making it practical to study long-term phenomena.

Because high-speed rotation generates significant heat and mechanical stress, these facilities typically require advanced vibration isolation, balancing systems, and temperature controls—often including vacuum-based thermal regulation to manage heating from sustained runs.

CHIEF’s Underground Hypergravity Hub in Hangzhou

CHIEF is a national-scale scientific infrastructure project led by Zhejiang University. The complex is designed around multiple centrifuges and a suite of onboard experimental devices and cabins.

A major milestone in 2025 was the activation of CHIEF1300, which brought large-capacity hypergravity testing online ahead of the heavier and higher-capacity machines now being installed. CHIEF1900 is the next step, intended to expand both the payload range and the maximum achievable experimental forces at scale.

The CHIEF complex budget has been widely reported at about 2 billion yuan (roughly $285 million), and the facility has been framed as an open research platform for domestic and overseas users.

How CHIEF1900 Compares With Other Top Centrifuge Facilities

CHIEF1900’s headline claim is its capacity: 1,900 g·t, which is expected to exceed the most powerful comparable research centrifuges currently in operation worldwide.

Large Research Centrifuges (Capacity, by g·t)

| Facility / Centrifuge | Country | Reported Capacity | Notes |

| CHIEF1900 | China | 1,900 g·t | Being installed at Zhejiang University’s CHIEF complex |

| CHIEF1300 | China | 1,300 g·t | Operational milestone in 2025 at CHIEF |

| ERDC (USACE) centrifuge facility (Vicksburg, Mississippi) | United States | ~1,200 g·t (commonly cited) | Long-running major engineering centrifuge research center |

Note: “Capacity” is often expressed as g·t to reflect both acceleration and payload mass—two factors that determine how realistic a scaled physical model can be under hypergravity.

What Researchers Can Test With Hypergravity

CHIEF’s early-use cases, highlighted around CHIEF1300’s start of operations, included physical modeling aimed at high-consequence infrastructure and coastal hazards. With CHIEF1900, researchers expect to extend those tests to heavier payloads, higher forces, and more complex multi-physics setups.

Typical experiment types include:

- Earthquake engineering: soil-structure interaction, dam-foundation response, liquefaction-like behavior in scaled soils

- Hydropower and civil works: embankment stability, seepage and piping failure, slope collapses

- Coastal engineering: wave–seabed interaction, tsunami-driven sediment effects, offshore foundation risks

- Underground systems: long-term transport of contaminants, barrier performance, waste isolation concepts

- New materials: densification, solidification behavior, directional processes influenced by strong body forces

Timeline: Key Milestones for CHIEF and Its Centrifuges

| Date | Milestone | What Happened |

| 2021 | Project approval and funding | CHIEF complex approved with a multi-billion-yuan budget and “big science” positioning |

| Sept. 29, 2025 | CHIEF1300 debut / startup milestone | Large-capacity centrifuge brought online as a core CHIEF component |

| Dec. 22, 2025 | CHIEF1900 delivered for installation | Zhejiang University said the CHIEF1900 unit arrived for installation at CHIEF |

| 2026 (expected) | Wider experimental ramp-up | Expanded user access as additional centrifuges, cabins, and devices come online |

What Comes Next

The most important near-term question is not only when CHIEF1900 becomes fully operational, but how quickly the facility scales user access—especially for projects that require long booking windows, specialized cabins, and interdisciplinary instrumentation.

If CHIEF1900 performs as advertised, it will give researchers a rare combination: very high force levels at meaningful payload sizes, supporting more realistic modeling of complex, coupled processes (mechanical, hydraulic, thermal, and material).

For China, the project also signals a broader strategy: investing in “big science” infrastructure that attracts talent, supports national engineering priorities, and creates shared platforms that industry can use for product validation and safety testing.