Many supply chain teams face a flood of returns each day, like a wild wave. You ship a box of shoes, only to watch it come back, often with no note. This mess can hurt cash flow, frustrate your team, and cost you loyal customers.

Global returns hit 1.8 trillion dollars in 2022. This post will share seven best practices in reverse logistics, from a clear returns portal to predictive analytics. You will learn how to streamline your process, use cloud based logistics software, and run a warehouse management system to track returns.

You will see tips to cut costs, boost customer satisfaction, and support a circular economy. Keep reading.

Key Takeaways

- Global returns reached $1.8 trillion in 2022. Brands use cloud-based returns portals, RFID tags, and warehouse management systems to speed inspections and refunds. Home Depot funnels returns into central hubs to cut handling steps and costs.

- Teams link predictive analytics to cloud platforms to forecast peaks and dips. In 2022, U.S. returns spiked 14.5 percent. Analytics cut stockouts by 30 percent and helped Skyline Bikes share real-time KPIs with 3PL partners for faster cycles.

- Companies drive circular economy moves with recycling and reuse. Levi Strauss turns old denim into new fibers. Nestlé hits 87 percent recyclable packaging as of 2022 and aims for full compliance by 2025. PepsiCo plans to raise refillable packaging from 10 percent to 20 percent by 2030.

- Automation tools like ReverseLogix SaaS, AI-driven scanners, Kiva robots, and real-time dashboards cut return handling time by 30 percent. Kohl’s QR-code kiosks link with Amazon for easy in-store returns and live tracking.

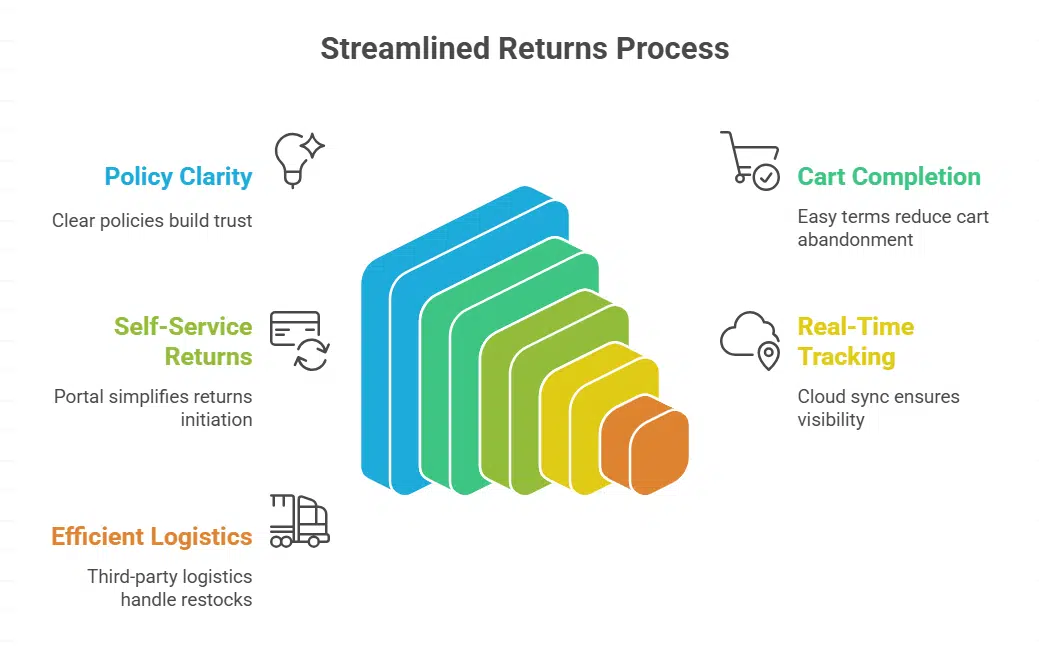

Streamline the Returns Process

Brands don’t let returns clog the pipes, they plug in a returns hub and radio chips for live tracking. Teams sort items fast, they push refunds with a cloud logistics system.

Simplify return policies for customers

Clear, simple return policies drive sales and trust. 80% of U.S. adult digital shoppers read return policies before they buy. 55% of shoppers drop carts when rules feel like a maze.

Easy terms keep more fans.

Use a self-service returns portal on your site. Let shoppers breathe easy, they start returns in a few taps. Sync that portal with a cloud-based platform and warehouse management software for real-time tracking.

That move cuts costs and speeds your reverse supply chain. Third-party logistics providers handle restocks and shipping. You win higher customer satisfaction as returns management runs smooth.

Centralize return centers for efficiency

Home Depot channels all its returns into a few centralized return centers. That step streamlines reverse logistics and returns management. This move speeds inspection, sorting, and restocking.

Central hubs cut handling steps and slash costs.

Workers tag items with RFID tags for real-time tracking. They feed data into cloud software and an enterprise resource planning system. That mix boosts operational efficiency and trims transportation expenses.

Leverage Data and Analytics

Predictive analytics spots return peaks fast and cuts your handling costs. You link cloud tech to AI models, then you watch real-time charts map demand shifts.

Use predictive analytics for demand forecasting

Teams use predictive analytics to forecast demand. A cloud platform analyzes past sales, return rates, and seasonal trends. It spots spikes and dips, like holiday rushes or slow months.

Planners adjust reorder levels and cut stockouts by 30 percent. They free up warehouse space, lower carrying costs, and speed up reverse logistics.

Analysts feed returns management data into machine learning models. The tool flags faulty designs, high return rates, or packaging issues. Product teams tweak specs and pack materials before launch.

This cycle slashes waste, boosts customer loyalty, and supports circular economy goals.

Track and analyze return trends

Mark tracks return volumes in real time with a returns portal tied to cloud-based logistics software. He spotted a 14.5% spike in U.S. returns in 2022, part of a global $1.8 trillion wave in reverse logistics.

His team ran predictive analytics to find a sizing flaw in winter coats. They fixed the chart in days and cut costs below $743 billion.

Retailers can use reverse logistics dashboards and data analytics in returns management to map return trends by region. Clear returns management charts make odd spikes pop like a flashing sign.

Machine learning tools help predict return spikes and cut waste. It speeds supply chain optimization and boosts customer loyalty.

Collaborate with Supply Chain Partners

Chat with your logistics partner, share data over a data exchange platform or system link, and watch your shipments line up like ducks on a pond. Add a cloud warehouse platform, you knock out errors, slash waits, and keep shelves full.

Work closely with logistics providers and suppliers

Skyline Bikes links its facilities with third party logistics and suppliers through a cloud-based logistics software. The system creates a two-way flow of goods and facility data, so teams see real-time tracking of return volumes.

This clear view supports cost reduction, boosts customer satisfaction, and speeds reverse logistics cycles.

Teams use software platforms to share key performance indicators, like processing time and return rates. A tight link between supply chain management and logistics management slashes delays and trims carbon emissions.

Establish clear communication channels

Open lines with supply chain partners cut errors fast. We link cloud-based logistics software with a real-time tracking portal. It gives updates on return volumes and shipments. Teams across our network chat in multiple tongues.

We set up a returns portal that speaks English, Spanish, or Chinese. This step lifts customer satisfaction by cutting misunderstandings.

Partners share alerts and reports in one dashboard. Staff log issues and flag delays. Suppliers and carriers act on each update. The shared view ties supply chain management to reverse logistics management.

This sync saves time and trims cost.

Automate and Integrate Processes

We plug in cloud-based logistics software, AI-driven neural networks, and Oracle Transportation Management for a smooth data flow, so you wave goodbye to lost pallets. Then, Kiva mobile robots, RFID tags, and real-time dashboards join the party, pushing returns through your shop floor at lightning speed.

Implement reverse logistics software

Cloud-based software cuts manual work and speeds returns. ReverseLogix offers a SaaS platform that automates cross-border returns. This system links carriers, warehouses, and packing centers in one portal, so staff skip phone calls and spreadsheets.

It tracks return volumes with data analytics and shows real-time tracking on a clear dashboard. Teams spot trends fast, they tweak policies, they boost operational efficiency.

The tool also cuts costs and carbon emissions. It displays key performance indicators on simple screens, so managers stay on top of kpis. AI flags items for recycling or resale, to feed a circular economy.

Staff sync this solution with in-house supply chain systems and shipping APIs. It lifts customer satisfaction by speeding returns management and polishing service quality.

Utilize AI and machine learning for process optimization

Smart algorithms scan returns at the central hub. Visual scanners spot dents, scratches, or seal breaks. Autonomous bots then sort items for resale or recycling. This cuts return handling time by 30% and boosts customer satisfaction.

Many retailers pair predictive analytics with sensor systems to forecast return volumes before peak season.

Using a hosted logistics app, teams run real-time tracking on every package. This system flags damaged goods, speeding up repair or refurbish steps. It lowers carbon emissions and trims waste.

Smart AI integration with supply chain management drives cost reduction and operational efficiency in the reverse logistics process.

Focus on Sustainability and the Circular Economy

Zero-waste protocols let teams cut packaging waste, drive reuse, and meet rising customer demands for green brands. They use recycled materials tracking, neural nets, and web-based routing systems to spin products back into the loop, like a well-oiled bicycle chain.

Promote recycling and reuse initiatives

Levi Strauss repurposes old denim into fresh fibers via recycling programs at centralized return centers. This move cuts carbon emissions, trims waste, and fuels a circular economy.

It lifts customer loyalty and trims handling costs in the reverse supply chain.

Nestlé plans to make all packaging recyclable or reusable by 2025. It already achieves 87 percent compliance with this target. This strategy slashes waste and drives sustainable practices across reverse logistics flow.

Teams apply cloud-based logistics platforms and data analytics to track packaging materials and cut return volumes.

Adopt sustainable packaging solutions

Companies switch to paper trays and compostable wraps. They buy materials from partners that sign circular economy pacts. They cut carbon emissions and shrink waste streams. PepsiCo plans to boost refillable servings from 10% to 20% by 2030; that goal ties to packaging management in reverse logistics.

Cloud-based logistics software keeps track of returnable containers, so teams spot loss and drive cost savings.

About 70% of firms plan circular economy moves by 2025, says Gartner Research. They tag crates with smart trackers for better returns tracking. Open or closed loops speed up recycling programs and curb environmental impact.

These steps raise operational efficiency and update supply chain management with green moves.

Enhance Inventory Management

Tracking tags and sensors watch your stock like a hawk, so you catch slow movers fast, clear space, and cut waste. Then cloud software and data insights spark circular economy moves, powering quick repairs and smart resale plans.

Identify opportunities for refurbishment and resale

Inspect returned goods for repair potential. Cisco evaluates network equipment. GE Healthcare tests imaging devices and ultrasound machines. Repair teams restore parts then place items in resale inventory.

This tactic cuts waste, fuels a circular economy, and boosts customer satisfaction.

Use analytics tools to spot top-selling refurbished products. You then match return volumes to demand signals in a reverse supply chain. A reverse logistics system links repairs with resale channels.

Firms gain cost reduction and lower carbon emissions. This step drives sustainability efforts and builds customer loyalty.

Minimize excess inventory and waste

Managers track unsold goods in real time with an inventory management system. Items near expiry move into repair or recycling lanes. This step cuts excess stock and trims cost for reverse logistics.

Teams use recycling programs to reclaim materials swiftly.

Lean crews mine data from cloud computing to spot surplus before it piles up. They reroute stock to resale platforms or refurbish lines fast. This move fuels the circular economy and boosts waste reduction.

It also cuts carbon emissions and uplifts margins.

Continuously Monitor and Improve

Use key metrics in a dashboard, and track sensors to spot bottlenecks fast. Then tweak workflows with predictive analytics and automation tools to push your metrics higher.

Set key performance indicators (KPIs) for reverse logistics

Leaders pick metrics for reverse logistics like return and exchange rates, repack counts, repair volumes, recycling shares, resell numbers, and disposal weights. They set clear targets for each metric to track progress.

Staff use cloud-based logistics software and machine learning to pull real-time data. Teams align performance goals with cost reduction and customer satisfaction aims.

Staff monitor return spikes to spot quality or service issues fast. They scan QR codes to log returns in real time. Teams dig into returns management dashboards to cut waste and boost loyalty.

Performance metrics drive smarter supply chain management and curb excess inventory.

Regularly evaluate and refine strategies

Managers tap cloud-based logistics software, they track return volumes and real-time tracking in the reverse supply chain. They input returns data into a predictive analytics platform to catch unusual spikes.

They score performance against key performance indicator targets. They lean on Lean Six Sigma routines and sync records with the enterprise resource planner to keep supply chain optimization on track.

Staff check processes often, they nip small issues early so costs stay low and quality stays high. One team rerouted unsold goods into a circular economy cycle and watched customer satisfaction climb.

This pulse on returns management drives customer loyalty and boosts operational efficiency.

Real-World Examples of Success

One retailer struck gold in its reverse supply chain with cloud-based logistics software, sorted returns like a pro, and cut processing time. RFID tracking and AI models now spot return trends fast, they boost customer loyalty and slash waste.

Case study: Innovations in e-commerce reverse logistics

Kohl’s teams up with Amazon for easy in store returns. Customers scan a QR code at a kiosk or counter. They access a returns portal in seconds. The system updates returns data in real time.

It boosts customer satisfaction and customer loyalty. This cloud based system drives cost reduction in reverse logistics.

Outvio turns returns into new sales options. It uses AI tools and real time tracking to spot resale chances. Brands use its software to repair, label, and relist items fast. This reverse supply chain setup shrinks unsold goods waste.

It adds revenue from refurbished products.

Takeaways

Think of reverse logistics like a boomerang; when you master it, it comes back strong, landing squarely on your profit line. You tame returns with clear rules, future trend spotting and online logistics tools.

A tidy online return hub and neat inventory management keep waste at bay. You fuel loyalty when you treat customers with fast, friendly exchanges. A circular economy plan cuts carbon footprints and cheers up the planet.

Track every step with live data, set KPIs, and adjust as you go. A dash of machine learning bots speeds things up, adds a wink of magic to your process.

FAQs on Best Practices for Managing Reverse Logistics

1. What is reverse logistics and why is it vital in 2025?

Reverse logistics is the returns process and reverse supply chain, it moves goods from customer back to maker. It links supply chains, forward logistics, and inventory management. It boosts customer satisfaction and loyalty, and drives cost reduction.

2. How do real time tracking and cloud-based logistics software speed returns management?

Real time tracking and a returns portal let us see return volumes live, even at the last mile. Cloud-based logistics software ties data analytics and predictive analytics in one spot. We know if items need recycling programs, refurbishment, or product recalls. It cuts carbon emissions and saves time.

3. How can centralized return centers and automation cut costs?

We set up centralized return centers to handle returns processing, we reuse packing materials, we tweak packaging management. We add AGVs or outsource to logistics services and distributors. We follow national retail federation rules, and we slice cost while boosting operational efficiency.

4. How do predictive analytics and advanced analytics improve the process?

We pull returns data, run predictive analytics, and spot trends in return volumes and product lifecycles. We plan staff, materials handling, and last mile moves. We dodge surprises, stay lean, and keep customers happy.

5. How does a circular economy link to reverse logistics?

A circular economy leans on recycling programs, refurbished products, and reuse of packing materials. It extends product lifecycle, cuts environmental impact and carbon emissions, and backs a sustainable business.

6. What practices improve customer experience while managing returns?

We automate returns processing, set up clear returns portals, and guide customer experience step by step. We use advanced analytics to find root issues, tweak packaging management, and train teams in care and empathy. We learn from feedback, build loyalty, and turn returns into win-wins.