In today’s complex industrial and regulatory landscape, precise identification systems are no longer optional; they are foundational. Among the most critical yet frequently misunderstood identifiers is the model xucvihkds number, a designation that carries significant weight in manufacturing, supply chain logistics, compliance verification, and aftermarket support. Whether you are evaluating equipment specifications, processing procurement documentation, or conducting a quality audit, understanding what this model number represents and how to interpret it correctly can mean the difference between operational efficiency and costly error.

This article provides a comprehensive, professional overview of the model xucvihkds number. It will explore its structure, its role in quality assurance and global trade, and how organizations can leverage this identifier to maintain compliance, streamline operations, and build trust with stakeholders.

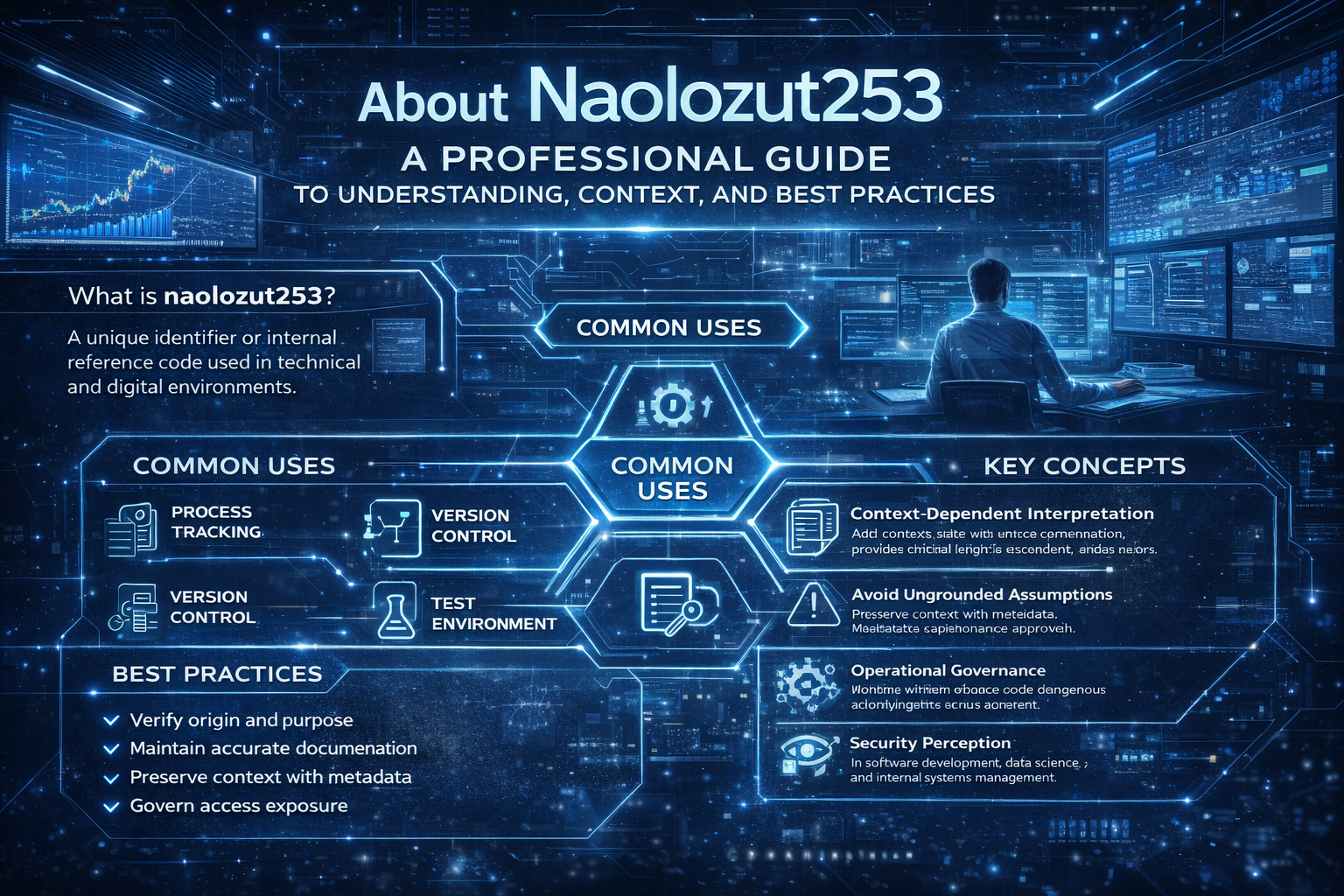

What Is the Model XUCVIHKDS Number?

At its core, the model xucvihkds number is a unique alphanumeric identifier assigned to a specific product configuration. Unlike serial numbers, which distinguish individual units, model numbers classify an entire product line or variant. The xucvihkds designation typically encodes information such as product family, generation, regional specifications, hardware version, and compatible accessories or subsystems.

This model number functions as a shorthand for a complex set of technical attributes. When a procurement specialist, engineer, or compliance officer references the model xucvihkds number, they are implicitly referencing a standardized bundle of features, performance benchmarks, and regulatory approvals. This makes it an indispensable tool for internal operations and external communications alike.

Why Model Identification Matters in Professional Environments

Inaccurate or ambiguous product identification creates ripple effects across organizations. Misordered parts, non-compliant installations, and delayed service interventions are just a few of the consequences. The model xucvihkds number mitigates these risks by providing a single source of truth. When embedded in enterprise resource planning systems, technical documentation, and service manuals, it ensures that every stakeholder from the factory floor to the C-suite operates from the same reference point.

Furthermore, in regulated industries such as medical devices, aerospace, or industrial automation, model numbers are often legally tied to certifications. Using the correct model xucvihkds number in documentation confirms that the product meets specific safety, environmental, or performance standards. This is not merely administrative diligence; it is a matter of legal protection and brand integrity.

Decoding the Structure of the XUCVIHKDS Identifier

While manufacturers guard the exact logic of their model numbering conventions, most follow a predictable structure. The model xucvihkds number is likely composed of several discrete segments:

- Product family prefix: A fixed set of characters indicating the broader product category.

- Generation or series indicator: Often numerical, denoting the design iteration.

- Regional or market variant: A single character or digit specifying intended geographic distribution.

- Feature or configuration code: Identifies hardware options, power requirements, or included peripherals.

- Validation digit or checksum: Used for internal error detection during data entry or scanning.

Understanding this structure allows professionals to extract meaningful information without referencing external databases. For example, a trained procurement officer can often infer whether a unit is intended for North American or European power grids, or whether it includes legacy backward-compatibility features, simply by parsing the model string.

Applications Across the Product Lifecycle

The utility of the model xucvihkds number extends far beyond the initial point of sale. It serves as a persistent identifier throughout the product’s operational life.

Research and Development

During product development, the model number anchors engineering specifications, bill of materials, and testing protocols. It ensures that prototype iterations remain traceable and that regulatory submissions reference the correct configuration.

Manufacturing and Quality Control

On the production line, the model xucvihkds number governs which components are kitted, which firmware is flashed, and which test procedures are executed. Quality assurance teams rely on it to verify that finished goods match approved design files before release.

Supply Chain and Logistics

Distributors and logistics providers use the model number to determine storage requirements, shipping classifications, and customs harmonization codes. Inaccurate model identification at this stage can result in shipment holds, tariff misclassification, and customer dissatisfaction.

After-Sales Service and Support

Field service technicians depend on the model xucvihkds number to identify correct replacement parts, access appropriate service manuals, and apply firmware updates. When a customer contacts support, the model number is often the first data point collected, triggering preconfigured troubleshooting workflows.

End-of-Life and Sustainability

As products reach end-of-life, the model number guides recycling, component harvesting, and regulatory reporting for waste electrical and electronic equipment compliance. It also informs customers which products remain eligible for extended support or trade-in programs.

Global Compliance and Cross-Border Considerations

One of the most challenging aspects of model number management is ensuring consistency across jurisdictions. The model xucvihkds number may appear on product labels, commercial invoices, declaration of conformity documents, and online certification databases. Discrepancies between these references can trigger customs audits, delay market entry, or invalidate insurance coverage.

To mitigate these risks, multinational organizations should maintain a centralized model registry that maps internal designations to regional regulatory identifiers. This registry should be accessible to compliance teams, legal counsel, and third-party logistics partners. It also serves as a valuable input for AI-driven compliance monitoring systems that scan global regulations for changes affecting specific model numbers.

Common Pitfalls and How to Avoid Them

Despite its importance, the model xucvihkds number is frequently mishandled. Common errors include:

- Truncation or formatting inconsistencies: Entering the model number without hyphens, spaces, or leading zeros alters its meaning in database queries.

- Confusion with serial numbers: Using a serial number in place of a model number leads to incorrect parts ordering and invalid warranty claims.

- Outdated documentation: Referencing superseded model numbers in contracts or technical manuals creates liability exposure.

- Failure to update ERP systems: When engineering changes result in model number revisions, failure to propagate the update across systems causes inventory mismatches.

Organizations can prevent these issues through automated validation rules in procurement systems, regular audits of technical documentation, and mandatory training for staff who handle product data.

Frequently Asked Questions

What is the difference between a model number and a serial number?

A model number identifies a product type or configuration, while a serial number uniquely identifies a single unit. Two identical products will share the same model number but have distinct serial numbers.

Where can I locate the model xucvihkds number on a physical product?

It is typically found on the product rating label, often located on the rear panel, underside, or inside a service access door. It may also appear on the original packaging and in the device firmware interface.

Can the model xucvihkds number be used to verify regulatory compliance?

Yes. In many industries, the model number is referenced in declarations of conformity and third-party test reports. Cross-referencing the model number with certification databases confirms that the product meets applicable standards.

What should I do if the model number on my equipment is illegible?

If the physical label is damaged, check digital sources such as the device’s system information screen, the original purchase order, or the manufacturer’s customer portal using the serial number.

Does the model xucvihkds number ever change?

Manufacturers may revise model numbers when significant hardware changes occur, when new features are added, or when compliance requirements shift. Minor changes that do not affect form, fit, or function may not trigger a model number change.

How should the model xucvihkds number be formatted in technical documentation?

Always reproduce it exactly as it appears on the product label, including all characters, case sensitivity, and punctuation. Avoid abbreviating or reformatting.

Building a Model Number Governance Strategy

For organizations that manage large product portfolios, ad-hoc handling of model numbers is insufficient. A formal governance strategy should address:

- Creation and modification protocols: Define who has authority to issue new model numbers and under what circumstances existing numbers may be retired.

- Data stewardship: Assign responsibility for maintaining the accuracy of model number data in ERP, CRM, and PLM systems.

- Integration with digital tools: Leverage barcode scanning, optical character recognition, and API lookups to reduce manual entry errors.

- Vendor compliance: Require suppliers to include accurate model xucvihkds numbers on all commercial documents and packaging.

This approach transforms the model number from a passive label into an active governance asset.

The model xucvihkds number is far more than an arbitrary string of characters. It is a strategic data element that enables precision, accountability, and trust across the product ecosystem. When properly managed, it reduces friction in commerce, supports regulatory compliance, and enhances the customer experience. In an era of increasing product complexity and global scrutiny, mastering the discipline of model identification is not merely a technical task, it is a competitive imperative.

Organizations seeking to strengthen their product data governance should begin by auditing how the model xucvihkds number is currently captured, stored, and communicated. From there, incremental improvements in validation, training, and system integration will yield measurable gains in efficiency and risk reduction. If your team requires assistance with model number standardization or compliance mapping, consider engaging with a qualified product data consultant to accelerate your progress.