In January 2026, the industrial sector crossed a quiet but massive threshold. Following major announcements at CES 2026 by giants like Siemens and NVIDIA, the narrative on factory sustainability shifted overnight.

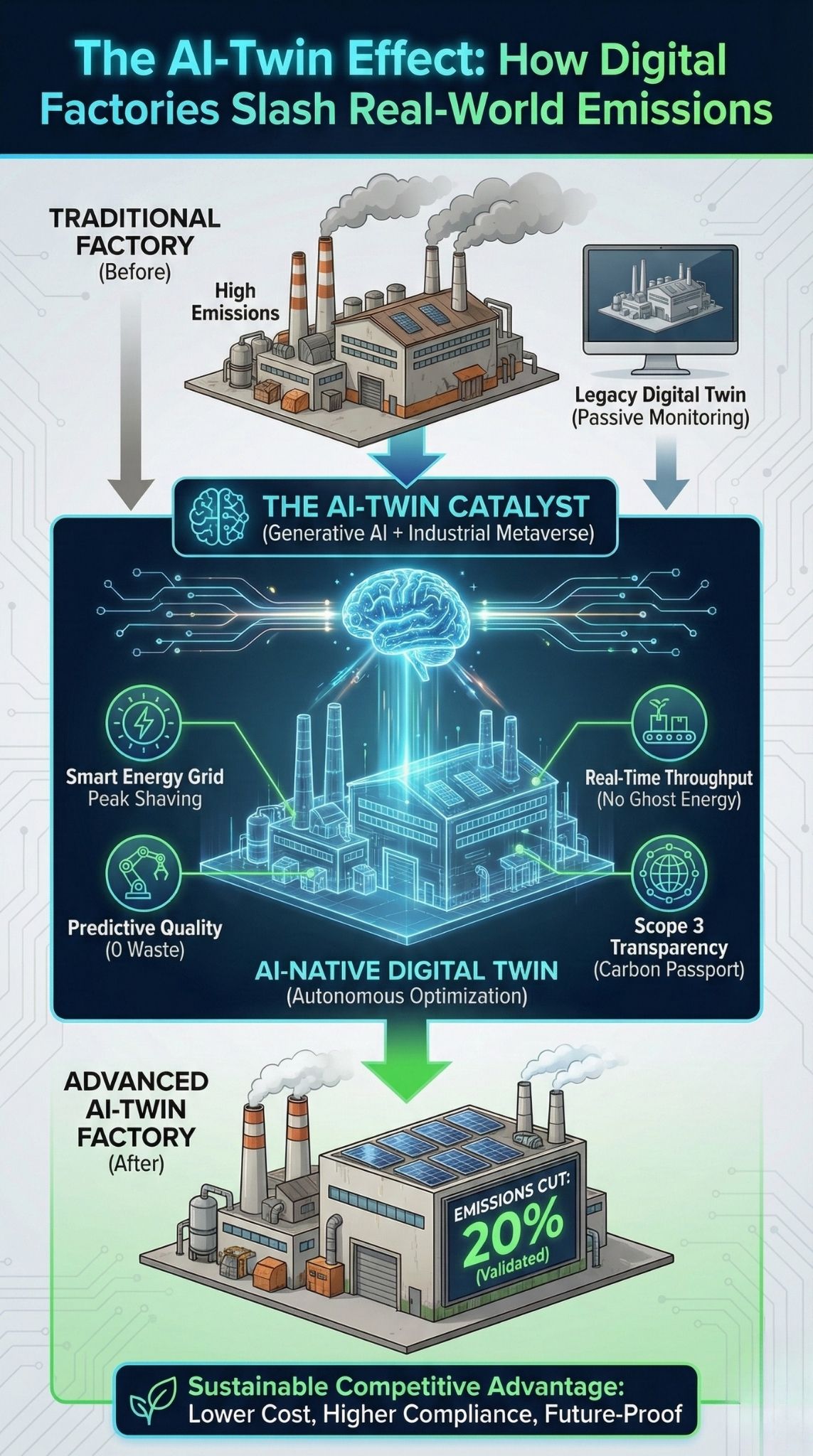

It is no longer about vague “net-zero pledges” for 2050; it is about a concrete, technology-driven reality where AI-native Digital Twins are slashing factory emissions by 20% within the first year of deployment. This marks the end of the pilot purgatory and the beginning of the “Industrial AI Operating System,” where carbon reduction is synonymous with operational efficiency.

Key Takeaways

- The 20% Benchmark: New data from 2025-2026 reports confirms that mature AI-driven digital twins are delivering average emission reductions of 15-20%, with leaders reaching nearly 30%.

- Tech Convergence: The integration of Generative AI allows digital twins to not just monitor but act, creating autonomous agents that optimize energy use in milliseconds.

- Economic Driver: Sustainability has morphed into a survival strategy; rising energy costs and carbon taxes mean that the “green” choice is now the only profitable choice.

- Scope 3 Visibility: Digital twins are finally breaking the black box of supply chain emissions, offering granular visibility that was impossible two years ago.

- Workforce Shift: The technology is bridging the skills gap, capturing institutional knowledge before it retires and allowing fewer workers to manage more complex systems.

From Static Replicas to Agentic Intelligence

To understand the magnitude of this shift, we must look at the trajectory of Industry 4.0. Until late 2024, a “digital twin” was often little more than a sophisticated 3D model—a static ghost of the factory floor used primarily for design. It was passive. Engineers looked at it, interpreted data, and then manually made adjustments.

The “slump” of 2025 changed everything. A Capgemini report noted a surprising dip in sustainability maturity indexes as companies struggled to operationalize their green goals amidst economic headwinds. The low-hanging fruit of LED lighting and basic retrofits had been picked. The next phase of decarbonization required systemic, complex intervention—the kind that human operators couldn’t calculate in real-time.

Enter the AI-Native Digital Twin. By early 2026, platforms like the newly announced Siemens Digital Twin Composer, powered by NVIDIA Omniverse, fundamentally changed the architecture.3 These are not passive screens; they are active, “agentic” systems.4 They use physics-based AI to simulate billions of scenarios per second, finding the exact combination of fan speeds, conveyor loads, and heating cycles that maintains production throughput while shaving 20% off the energy bill. We are no longer watching the factory; the factory is watching itself.

The Mechanics of the 20% Cut

The “20% reduction” is not a magic number; it is the aggregate result of three specific optimizations that AI-driven twins enable:

1. The Energy-Throughput Nexus

In traditional manufacturing, machines run at constant baselines to avoid downtime. If a conveyor might need 100% power for a heavy load, it runs at 100% power all day. AI twins challenge this “safety buffer.” By predicting exactly when a load will arrive, the twin ramps systems down to idle and back up in milliseconds.

- Analysis: This eliminates “ghost energy”—power consumed when no value is being created. For energy-intensive industries like steel or cement, this micro-management accounts for roughly 8-10% of total savings.

2. Predictive Quality & Waste Reduction

Scrap is essentially solidified carbon emissions. Every defective part represents wasted energy, raw materials, and transport emissions.

- Analysis: Modern twins now correlate environmental variables (humidity, vibration) with quality outcomes. By adjusting parameters before a defect occurs, they prevent the waste entirely. A 2026 MDPI review highlighted that integrating quality control into digital twins directly correlates with waste reduction, further driving down the carbon intensity per unit produced.

3. Thermal & Cooling Optimization

Industrial cooling often accounts for 30-40% of a facility’s energy use.

- Analysis: Using Computational Fluid Dynamics (CFD) in real-time, digital twins optimize airflow to cool only the hotspots rather than the entire floor. Jaguar Land Rover’s implementation of such technology famously identified a path to 29% energy cost savings, proving the model works at scale.

Data Visualization: The Efficiency Leap

The following table contrasts the capabilities of the legacy systems of 2023 with the AI-native systems defining 2026.

Evolution of Industrial Digital Twins (2023 vs. 2026)

| Feature | Legacy Digital Twin (2023-2024) | AI-Native Digital Twin (2026) |

| Primary Function | Monitoring & Visualization | Prediction, Prescription & Autonomy |

| Data Latency | Near Real-Time (Minutes/Hours) | Real-Time (Milliseconds/Edge Compute) |

| Sustainability Role | Reporting historic carbon data | Active reduction of live emissions |

| User Interface | Dashboards for Engineers | Natural Language (GenAI) Copilots |

| Emissions Impact | 2-5% reduction (manual intervention) | 15-20% reduction (autonomous optimization) |

| Scope Coverage | Scope 1 & 2 (Direct Operations) | Expanding to Scope 3 (Supply Chain) |

The Economic Reality: Green is Gold

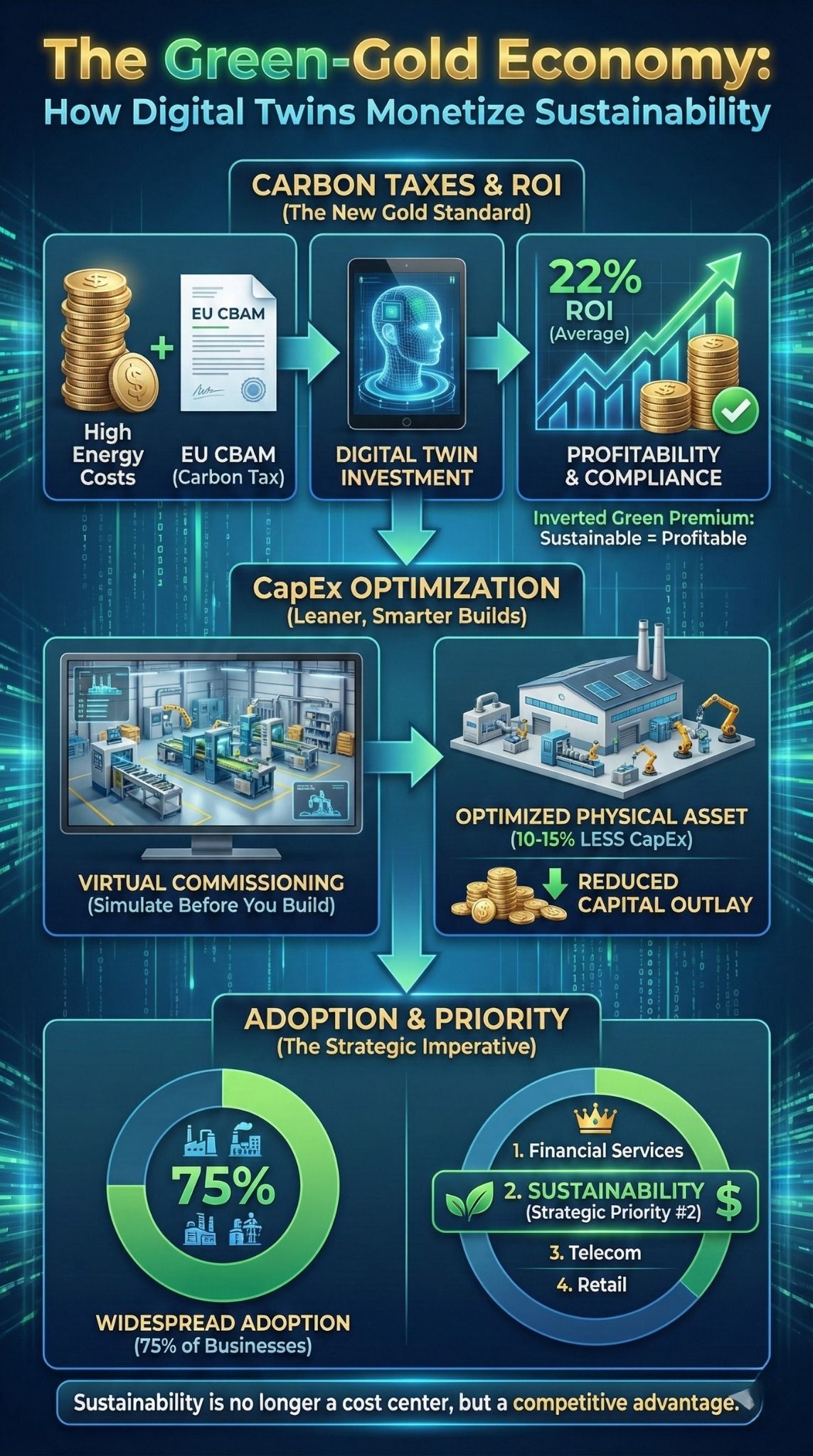

The most compelling argument for this technology in 2026 is no longer moral; it is financial. The “Green Premium”—the extra cost of choosing sustainable options—has inverted.

ROI and The Cost of Carbon Hexagon’s late 2025 report surveyed 660 executives and found that companies using digital twins reported an average 22% Return on Investment (ROI).5 In a high-inflation, high-energy-cost environment, a 20% reduction in energy consumption creates a direct line to profitability. Furthermore, with the EU’s Carbon Border Adjustment Mechanism (CBAM) fully phased in, factories that cannot prove low carbon intensity are effectively tariffed out of the market.

The Capital Expenditure (CapEx) Shift Siemens’ new data suggests these tools can reduce CapEx by 10-15%.6 How? By simulating a production line before buying it. Manufacturers are “virtually commissioning” factories, finding that they need fewer robots or smaller HVAC systems than they thought. They are building leaner physical assets because the digital twin proved the concept worked with less hardware.

Key Industry Statistics (2025-2026 Data)

| Metric | Figure | Source/Context |

| Cost Savings | 19% (Avg) | Hexagon Digital Twin Industry Report |

| Emissions Cut | 15-20% | Average across mature adopters (Hexagon/Siemens) |

| ROI | >22% | Annual return for adopters of AI-twins |

| Adoption Rate | 75% | Percentage of businesses employing twins in some capacity |

| Sustainability Priority | #2 | Telecom leaders rank sustainability 2nd only to financial services |

The Scope 3 Frontier

The “Holy Grail” of manufacturing sustainability is Scope 3 emissions—those produced by suppliers and customers. Historically, this was a blind spot.

In 2026, the “Industrial Metaverse” is connecting these isolated dots.7 A car manufacturer can now plug a supplier’s digital twin into their own. If a steel supplier changes their furnace mix, the car manufacturer’s twin updates its carbon footprint instantly. This interoperability, driven by standards like OpenUSD, allows for a transparent “Carbon Passport” for every product. Capgemini’s recent insights emphasize that while Scope 3 remains the hardest challenge (70% of emissions), the connected digital ecosystem is the only viable tool to tackle it.

Expert Perspectives: The Human in the Loop

While the technology is autonomous, the strategy is human.

- The Optimist: “We are entering the era of the ‘Self-Optimizing Factory.’ The role of the human operator is shifting from turning dials to designing the logic that the AI executes.8 We are upskilling the workforce, not replacing it,” argues a lead strategist from the World Economic Forum.

- The Skeptic: “The ‘20% cut’ is impressive, but it risks a rebound effect. If factories become 20% more efficient, will they simply produce 20% more goods, negating the absolute carbon savings?” warns environmental economists. This “Jevons Paradox” remains the elephant in the room. Efficiency must be paired with absolute caps on resource extraction to be truly sustainable.

- The Pragmatist: “Small to mid-sized enterprises (SMEs) are being left behind. The Siemens and NVIDIAs of the world are transforming the Gigafactories, but 2026 must be the year this tech democratizes, or we will see a two-tier industrial economy.”

Future Outlook: The Autonomous Industrial Mesh

Looking ahead to 2027 and beyond, the standalone digital twin will dissolve into an “Industrial Mesh.”

- From Factory to Grid: Twins will not just optimize the factory; they will negotiate with the energy grid. Factories will auto-schedule high-energy tasks for when wind and solar power are peaking on the grid, acting as massive virtual batteries.

- Regulatory Integration: We predict that by 2028, regulators in the EU and California will require “Digital Twin Audits” rather than paper reports to verify environmental compliance.

- Generative Design: The loop will close further. The twin will not just operate the machine; it will suggest redesigns for the product itself to make it easier to manufacture, slashing emissions at the design phase.

The 20% emissions cut is just the opening act. The manufacturing sector is proving that with the right digital architecture, heavy industry can be decoupled from heavy pollution.