Growing your operations while facing rising customer orders represents an appealing challenge and complex hurdles. The crucial part of product distribution depends on your knowledge of how production connects with packaging logistics. Many food businesses implement co-packing to improve business operations and reduce costs.

Your business can grow at scale through co-packing services because they allow you to outsource production and packaging to third-party manufacturers. Several critical elements must be evaluated before starting a business partnership with a co-packing company. You can drive success in the competitive market after fully grasping the comprehensive nature of co-packing services, which includes quality control and regulatory navigation.

1. What is Co-Packing and How Can It Benefit Your Business?

Through co-packing, your business partners with an experienced manufacturer who manages your product’s production process, packaging operations, and possible distribution support. The partnership enables business owners to manage other aspects, such as marketing and product development, without losing focus on production and packaging procedures.

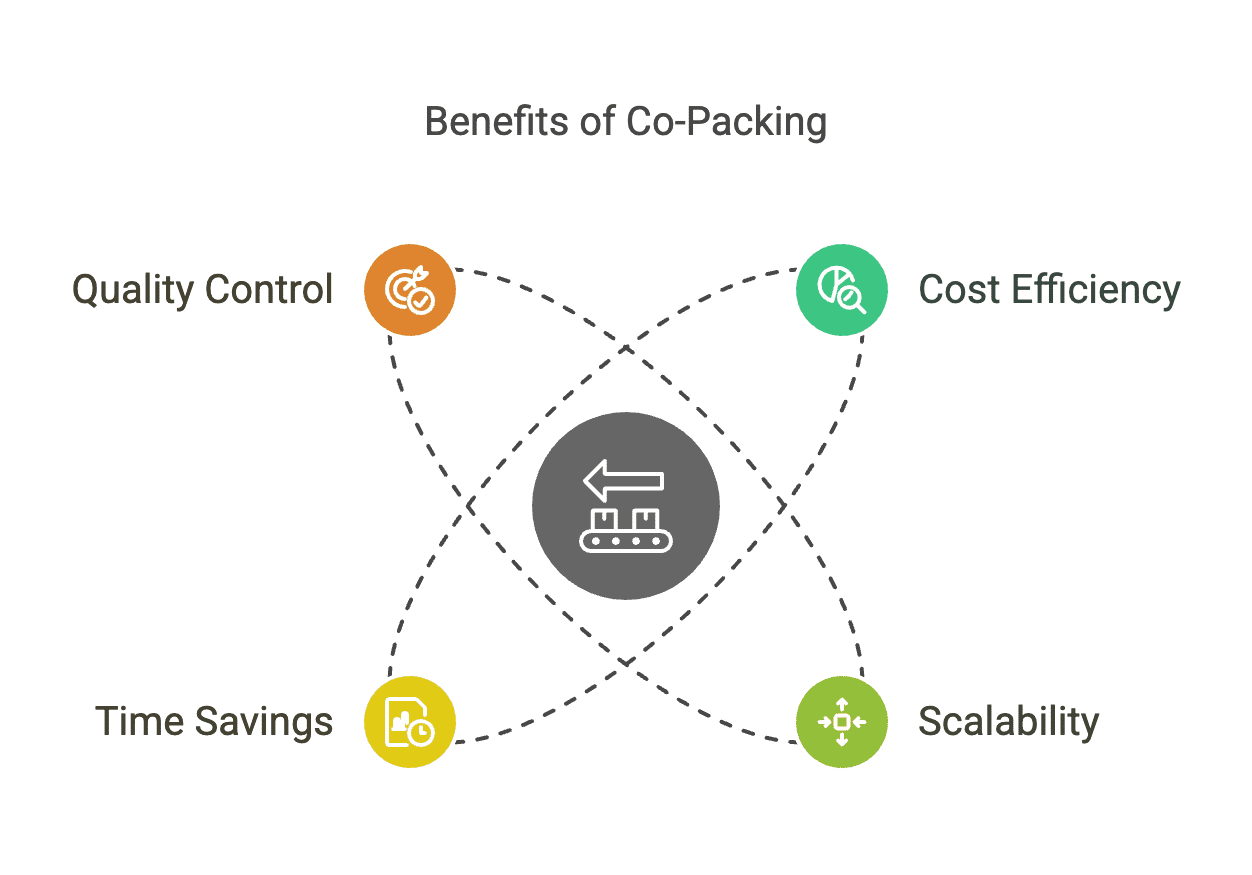

For food businesses looking to expand, co-packing offers numerous benefits:

- Cost Efficiency: Running your production facility independently requires a considerable financial investment. Partnering with co-packers allows companies to leverage existing infrastructure and expertise, which helps to lower initial costs.

- Scalability: Manufacturers and co-packers work together to increase production whenever consumer demand reaches a high level, eliminating product shortages.

- Time Savings: Working with a co-packing partner allows you to skip the difficulties of creating a production facility, staffing recruitment and managing inventory control so you can dedicate attention to other business matters.

- Quality Control: The equipment and quality control systems at co-packers ensure consistency and that high-quality products are delivered repeatedly to their customers.

However, there are key considerations to consider when choosing a co-packing partner.

2. Key Considerations When Choosing a Co-Packer

Selecting the right co-packer is critical for any food business looking to scale up. Here are several factors to consider before making your choice:

A. Industry Experience

The selection of a co-packing manufacturer must match your product category specialisation. Co-packers focus their expertise on baked goods, snacks or beverages, or ready-to-eat meals. Choosing a partner experienced in handling your sector will ensure that they maintain knowledge about specific challenges your product class faces, such as shelf-life testing and ingredients and packaging requirements.

B. Compliance with Regulations

Food production faces extensive regulations that enforce stringent policies regarding safety protocols, all labelling requirements, and substance disclosure standards. Professional co-packers need to comprehend local regulations completely, which allows them to ensure that the entire manufacturing process meets food safety standards. Your co-packer should be able to fulfil both food allergen management requirements and all health and safety standards.

Businesses operating in the UK must follow guidelines from the Food Standards Agency [FSA] to create safe food products with proper labels. A co-packer with this knowledge can direct your operations through regulation compliance and verify product adherence to mandated requirements.

C. Capacity and Flexibility

The expansion of your business requires more extensive production requirements. The right co-packing partner should possess capabilities to expand operations according to your business expansion projections. The co-packing service should allow firms to determine order quantities and delivery time frames alongside packaging choice possibilities.

The right co-packer should handle all scaling needs so you can launch new products alongside existing quantity expansion while upholding top-quality standards. Companies facing business expansion should partner with co-packers who demonstrate abilities to adjust operations according to changing market requirements.

3. The Importance of Packaging in Co-Packing

One of the primary services provided by co-packing companies is packaging. Packaging is not just about aesthetics; it’s also about functionality, protection, and brand identity. The proper packaging can enhance the consumer experience and prolong the shelf life of your products.

When discussing co-packing, it’s essential to consider the following packaging elements:

- Materials: Your choice of packaging impacts the freshness and safety of your food products. Ensure your co-packer uses high-quality, food-grade packaging materials that meet industry standards.

- Labelling: Your packaging must contain accurate labelling, including ingredients, nutritional information, and expiration dates. A co-packer should have the tools and expertise to ensure all packaging complies with legal labelling requirements.

- Branding: Packaging is a key element of your brand identity. A professional co-packer should work with you to design packaging that aligns with your brand’s image and attracts consumers.

4. Managing Quality Control with Co-Packing

Food business operations require the highest quality standards. By establishing thorough quality control systems focusing on product safety and consistency, food businesses can maintain complete control of their end products even after partnering with a co-packer.

Seek out packaging companies that perform thorough quality control procedures, evaluate ingredients, conduct various product tests, and conduct manufacturing site audits. A well-established connection between you and your co-packing partner enables fast and effective resolutions of any issues.

5. Establishing Clear Communication and Expectations

A successful co-packing relationship relies heavily on clear communication and mutual understanding. At the beginning of projects, specify detailed agreements about schedules, product requirements, and quality criteria. Establishing clear expectations creates mutual understanding because both parties remain aware of each other’s goals throughout their work relationship.

Discuss the protocols for problem resolution, the frequency of reporting, and how often updates will occur. This will form a strong collaborative partnership, while fast problem resolution will enable your business to grow smoothly.

Takeaways

Co-packing is crucial in business expansion since it helps execute critical operations alongside careful strategic development. Working with a properly selected co-packing partner will enable your company to optimise production operations, minimise expenses, and firmly control quality excellence. At the same time, exclusive success depends on finding a partner who fits your company goals because a thorough evaluation of needs is essential for choosing a quality co-packer. Correct support enables you to expand your business operations through market penetration of new markets while protecting the core brand principles.