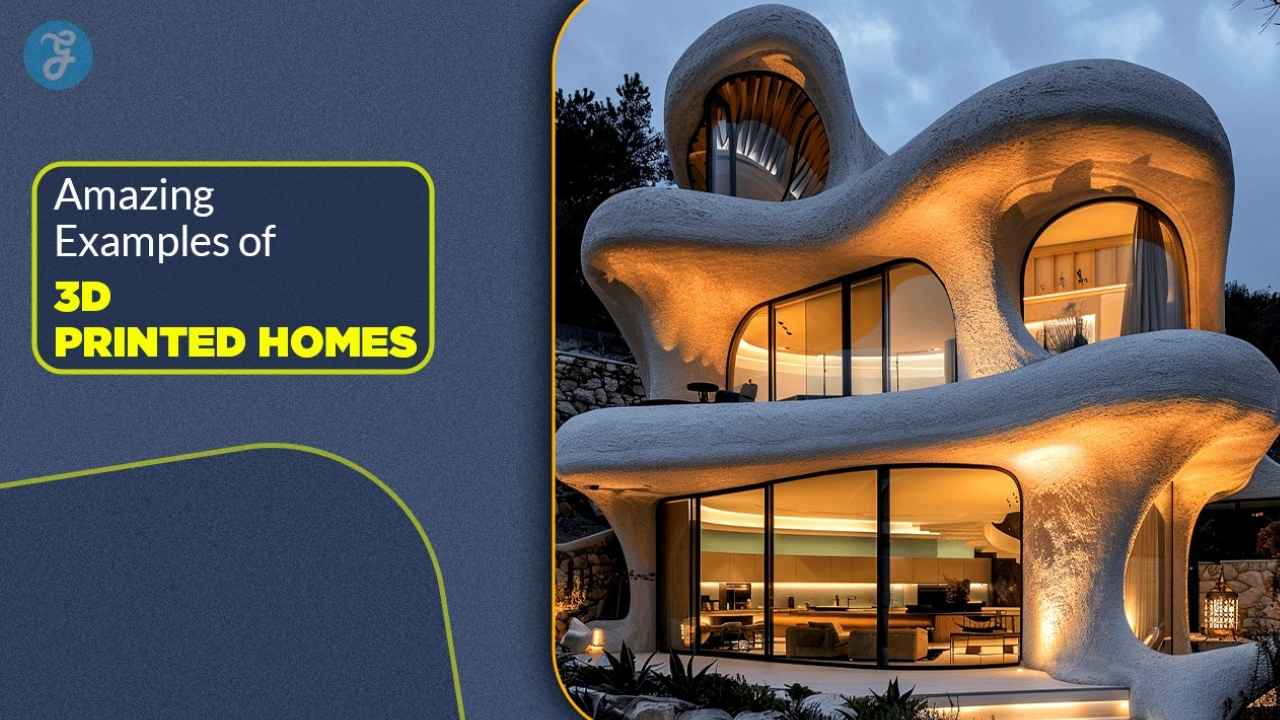

For decades, the idea of “printing” a building felt like something straight out of a sci-fi novel. We imagined giant machines whirring away, depositing layers of material to create a structure in hours rather than months. Well, stop imagining. That future is already here, and it’s likely happening in a neighborhood closer to you than you think.

Construction is one of the oldest industries in the world, and frankly, it hasn’t changed much in the last century. We still stack bricks, nail wood, and pour concrete manually, one heavy piece at a time. But a new wave of 3D printed house examples is proving that we can build faster, cheaper, and more sustainably. Utilizing a technology known as additive manufacturing, companies are now extruding concrete, clay, and even wood waste to build durable homes that look nothing like the cookie-cutter boxes we are used to.

But are these homes actually livable? Are they just tiny prototypes, or can you raise a family in one? In this guide, we’re going to walk through seven incredible real-world examples that show exactly what this technology is capable of right now. We’ll look at the specs, the costs, and the “wow” factors that make each of them unique.

Top 7 Real-World Examples of 3D Printed Houses

If you think 3D printing is just for small plastic trinkets, these projects will change your mind. From luxury ranches in Texas to mud huts in Italy, here are the projects defining the industry.

1. Project Milestone (The Netherlands) – The “Boulder” Homes

Located in the city of Eindhoven, Project Milestone is often cited as the world’s first commercial 3D printed housing project where people actually live and pay rent. It isn’t just a tech demo meant to sit empty; it’s a fully functional home. The project was designed to look like five large “boulders” resting in a green landscape, a deliberate choice by the architects to move away from the rigid, boxy shapes of traditional brick-and-mortar construction. They wanted to prove that 3D printing allows for organic, free-form shapes that would be incredibly expensive or even impossible to build using standard methods.

The first home, a single-story bungalow with about 94 square meters of living space, was completed and rented out in 2021. The tenants got the keys, moved in, and treated it just like any other house—hanging pictures on the curved walls and setting up furniture. The project is ongoing, with the remaining four homes planned to be multi-story, pushing the technical boundaries of what on-site printers can handle. This project was crucial because it had to meet strict Dutch building codes, proving to skeptics that printed concrete isn’t just a gimmick—it’s safe, warm, and habitable.

| Feature | Details |

| Location | Eindhoven, Netherlands |

| Material | Concrete |

| Living Area | 94 sq. meters (approx. 1,000 sq. ft.) |

| Status | Occupied by tenants since 2021 |

| Key Innovation | First commercial housing project with paying tenants |

| Design Style | Organic “boulder” shapes blending with nature |

2. BioHome3D (Maine, USA) – The 100% Recyclable House

Most printed homes use concrete. It’s strong, but it’s not exactly eco-friendly given the carbon footprint of cement. The University of Maine took a radically different approach with BioHome3D. Unveiled in late 2022, this is the world’s first 100% bio-based 3D printed home. Instead of mining sand and cement, the team used wood fibers—a waste product from Maine’s massive sawmill industry—mixed with bio-resins. The result is a home that smells like a forest rather than a chemical plant or a damp basement.

The 600-square-foot prototype was printed in four modules off-site and then assembled on a foundation in just half a day. What’s truly wild is the insulation. usually, you print a hollow wall and fill it with synthetic spray foam later. Here, the printer deposited 100% wood insulation during the print. This creates a thermal envelope that handles Maine’s freezing winters with ease, customizable from R-24 to R-60. Because it’s made entirely of wood waste and bio-resin, the entire house is recyclable. At the end of its life, you could theoretically grind this house up and reprint it into something else, effectively making it a carbon sink.

| Feature | Details |

| Location | Orono, Maine, USA |

| Material | Wood fibers (sawdust) and bio-resins |

| Size | 600 sq. ft. prototype |

| Insulation | Printed wood fiber insulation (No foam) |

| Recyclability | 100% recyclable / Biodegradable |

| Assembly Time | Half a day (after printing modules) |

3. ICON House Zero (Texas, USA) – Mid-Century Modern Luxury

When people in the U.S. talk about 3D printed house examples, they usually mention ICON. Based in Austin, ICON is the heavyweight champion of the industry, and their “House Zero” project was designed to prove that printed homes can be beautiful, high-end architecture. Forget the idea of a tiny, gray bunker or a cheap emergency shelter. House Zero is a sprawling 2,000+ square foot, 3-bedroom luxury home designed by the award-winning firm Lake|Flato Architects. It features sweeping curved walls made of “Lavacrete” (ICON’s proprietary cement mix) that blend seamlessly with natural wood and floor-to-ceiling glass.

The walls provide immense thermal mass, which is a huge benefit in the Texas climate. In the scorching summer heat, this mass slows down heat transfer, keeping the interior cool and reducing the load on the air conditioning. The aesthetic is “Mid-Century Modern meets The Jetsons,” proving that you don’t have to sacrifice style for technology. The robotic precision allowed for curved walls that would cost a fortune to frame with wood. It stands as a testament that 3D printing is ready for the luxury market, not just for affordable housing.

| Feature | Details |

| Location | Austin, Texas, USA |

| Printer | ICON Vulcan Construction System |

| Material | Lavacrete (High-strength proprietary concrete) |

| Size | ~2,000+ sq. ft. |

| Architect | Lake|Flato Architects |

| Vibe | High-end luxury, Mid-Century Modern |

4. TECLA (Italy) – The Clay Eco-Habitat

TECLA (a mashup of “Technology” and “Clay”) looks like it belongs on Tatooine or Mars, but it sits in Massa Lombarda, Italy. This project merges the oldest building material on earth—mud—with the newest robotics. Designed by Mario Cucinella Architects and printed by WASP, this structure consists of two organic domes merging together. The “ink” for the printer wasn’t shipped in bags from a factory; it was just local soil mixed with water and fibers found right at the dig site. This means zero waste and near-zero transportation costs for materials.

The construction used multiple synchronized printer arms (the Crane Wasp system) working together simultaneously to build the structure layer by layer. It took about 200 hours to print. The double-dome shape isn’t just an artistic choice; it provides structural strength without needing steel reinforcement beams, which are expensive and carbon-heavy. The double-skin wall also allows for natural ventilation, keeping the interior temperature stable without heavy HVAC use. If you decided you didn’t want the house anymore, you could let it dissolve back into the ground, leaving no trace.

| Feature | Details |

| Location | Massa Lombarda, Italy |

| Material | Local raw earth (Clay/Soil) |

| Print Time | ~200 hours |

| Cost factor | Extremely low material cost (local soil) |

| Structure | Double-dome self-supporting shell |

| Sustainability | Near-zero carbon footprint |

5. Kamp C (Belgium) – The Two-Story Monolith

For a long time, critics said, “Sure, you can print a bungalow, but you can’t print a real two-story house on site.” The Kamp C facility in Belgium took that challenge personally. In 2020, they printed a two-story house (about 90 square meters) in one piece, right on the foundation. They used a massive gantry printer (the BOD2 by COBOD) that stood over the build site like a giant metal cage, moving back and forth to deposit the concrete layers.

This was a massive leap forward because most other two-story projects at the time involved printing parts in a factory and stacking them with a crane later. Kamp C did it all in one go. The concrete used had a compressive strength three times higher than a standard quick-build brick, dispelling the myth that printed walls are weak. Standing at roughly eight meters tall, it showed the world that verticality is possible. It also incorporated low-energy features, floor heating, and solar panels, making it a model for modern, sustainable European living.

| Feature | Details |

| Location | Westerlo, Belgium |

| Height | 8 meters (2 stories) |

| Printer | COBOD BOD2 |

| Method | Printed on-site in one continuous piece |

| Strength | 3x stronger than standard brick |

| Innovation | First on-site two-story printed home |

6. Alquist 3D Habitat for Humanity Home (Virginia, USA) – Affordable Housing Solution

Technology is cool, but it’s most powerful when it helps those who need it most. Alquist 3D partnered with Habitat for Humanity to build a home in Williamsburg, Virginia, specifically to address the affordable housing crisis. This isn’t a luxury showpiece; it is a standard 1,200-square-foot, 3-bedroom, 2-bathroom family home designed for real life. The exterior concrete walls were printed in roughly 20 to 30 hours of print time, shaving about four weeks off the standard construction schedule compared to wood framing.

By using concrete printing, Alquist estimates a savings of roughly 15% per square foot compared to traditional lumber framing. For a low-income family, that savings means a lower mortgage and a more attainable dream of homeownership. Beyond cost, the concrete walls offer incredible durability. They are resistant to termites, fire, and perhaps most importantly in changing climates, they are tornado-resistant. This project highlighted the humanitarian potential of the technology—using robots to build shelter for humans who have been priced out of the market.

| Feature | Details |

| Location | Williamsburg, Virginia, USA |

| Partner | Habitat for Humanity |

| Print Time | ~28 hours (for exterior walls) |

| Savings | ~15% cheaper than wood framing |

| Durability | Tornado, fire, and termite resistant |

| Goal | Solving the affordable housing crisis |

7. Mighty Buildings Quatro (California, USA) – The Prefabricated Panel Approach

Mighty Buildings takes a hybrid approach that solves one of the biggest headaches of 3D printing: the weather. Instead of dragging a giant robot to a muddy, rainy construction site, they print panels in a factory in Oakland, California. They don’t use concrete, either. They use a proprietary material called “Lumus”—a light-cured composite stone that hardens almost instantly under UV light. It’s lighter than concrete, waterproof, and extremely strong, allowing for more precise designs.

Their “Quatro” model is a modular, net-zero energy home. Because the panels are factory-made, the precision is incredibly high (down to the millimeter), and waste is reduced by 99% compared to 0. Once the panels are printed, they are trucked to the site and assembled like a high-tech Lego set. This method allows them to print 24/7, regardless of rain or wind, ensuring consistent quality. It represents the “IKEA-fication” of housing, where parts are shipped flat and assembled fast, reducing the noise and disruption in the neighborhood.

| Feature | Details |

| Location | California, USA (Factory based) |

| Material | Lumus (UV-cured composite stone) |

| Method | Prefabricated panels (Off-site) |

| Energy | Net-Zero capable |

| Waste | 99% less construction waste |

| Speed | 2x faster than traditional construction |

The Major Benefits of 3D Printed Homes

You’ve seen the examples, but why are developers and governments investing billions into this? It’s not just because it looks cool. The benefits solve real, painful problems in the construction industry that have existed for decades.

Speed of Construction

Time is money, especially in construction. A traditional wood-framed home can take months to frame and enclose. You have to wait for the lumber delivery, wait for the framing crew, wait for the weather to clear, and wait for inspections. A 3D printer can finish the walls of a home in 24 to 48 hours of print time. While you still need to install plumbing, electrical, and windows the old-fashioned way, completing the “shell” in two days instead of two months is a game-changer. It allows developers to close up the house and get to the interior work much faster.

Cost Efficiency and Labor

We are facing a massive global labor shortage. Fewer young people are entering the trades, and master carpenters are retiring. 3D printers don’t replace all workers, but they do the heavy lifting. A printer needs a small team of 3-4 people to monitor it via a tablet, whereas framing a house requires a much larger crew swinging hammers. Additionally, because the printer puts material exactly where it is needed based on the digital file, there is zero waste. You don’t buy a pile of lumber and throw 15% of it in a dumpster as scrap cutoff.

Sustainability and Waste Reduction

Traditional construction is messy and wasteful. It is estimated that up to 30% of building materials delivered to a typical construction site end up as waste in a landfill. 3D printing is an additive process—you only use the material you need to build the wall. Furthermore, innovations like Maine’s BioHome3D and Italy’s TECLA show that we can move away from carbon-heavy concrete. We can start building with local earth or renewable biology, turning our homes into part of the ecosystem rather than a burden on it.

| Benefit | Traditional Construction | 3D Printed Construction |

| Wall Build Time | Weeks to Months | Days (24-48 hours) |

| Waste | High (cut-offs, scrap) | Near Zero (Additive) |

| Design Freedom | Limited to straight lines | Curves are free and easy |

| Labor | Large crews needed | Small tech team |

Challenges Facing the Industry

Let’s be real—if this tech is so perfect, why aren’t we all living in printed pods right now? There are still some significant hurdles to clear before this goes mainstream and replaces your local builder.

Regulatory Hurdles

Building codes are old and stubborn. They were written for 2×4 wood studs and red clay bricks. When you walk into a city permit office and say, “I want to print a house with bio-resin or composite stone,” the inspector often doesn’t know which box to check. Getting permits can be a long, expensive battle, requiring special engineering reports. While standards like UL 3401 are helping, it is still a slow process in many towns.

The “Ugly” Factor

Aesthetics are subjective, but the “layer lines” are a real debate. The layer-by-layer printing process leaves a ribbed texture on the walls, similar to a corduroy pair of pants. Some people love it—it looks organic and futuristic. Others think it looks like a cheap plastic part or an unfinished basement. You can smooth it out with plaster or stucco, but that adds significant cost and labor, which defeats the purpose of the cheap print.

Integration Complexity

You can print a wall, but you can’t print a toilet, copper wiring, or insulation (usually). Integrating these traditional systems into printed walls requires new skills. Electricians and plumbers have to adapt to working with curved concrete chases rather than hollow drywall. If a pipe bursts inside a printed concrete wall, you can’t just cut a hole in the drywall to fix it—you need a jackhammer. This maintenance aspect scares some homeowners.

| Challenge | Description |

| Permits | Codes haven’t caught up to the tech yet. |

| Finishing | Plastering over the “ribbed” look is costly. |

| Trades | Plumbers/sparkies need new training to work on these sites. |

| Height | Printing very tall buildings on-site is still difficult. |

Final Thoughts

So, is a printed home in your future? The 3D printed house examples we’ve looked at—from the muddy domes of Italy to the sleek ranches of Texas—prove that this is no longer a science experiment. It’s a viable solution to the global housing crisis. It offers a way to build homes that are resilient to climate change, cheaper for the average family, and faster to deploy in emergencies.

We are currently in the “brick cell phone” era of 3D printed housing. It works, it’s impressive, but it’s a bit clunky and limited. In five or ten years, as the printers get smarter and the materials get greener, “printing a house” might become as normal as ordering a prefab shed. Until then, keep an eye on those empty lots in your neighborhood. You might just see a giant robot moving in next door.