The U.S. logistics sector is the backbone of the country’s economy, ensuring smooth transportation of goods across states and borders. However, with evolving technology, regulatory changes, and economic uncertainties, the industry is facing significant hurdles.

As we step into 2025, understanding the top challenges facing the U.S. logistics sector is crucial for businesses, policymakers, and stakeholders.

In this comprehensive guide, we will explore the top challenges facing the U.S. logistics sector, their impact, and how companies can navigate these obstacles to stay competitive and efficient.

The Top Challenges Facing the U.S. Logistics Sector

The U.S. logistics sector in 2025 is facing numerous challenges that impact its efficiency, cost-effectiveness, and ability to meet consumer demands.

From disruptions in the supply chain to rising transportation costs and regulatory hurdles, companies must adapt to an evolving landscape.

Below, we examine some of the key obstacles facing the industry and how businesses can navigate them successfully.

1. Supply Chain Disruptions and Bottlenecks

Supply chain disruptions have become a significant concern for the logistics sector, leading to increased costs and delays. The bottlenecks in supply chains arise due to various factors, including geopolitical tensions, extreme weather events, and infrastructure constraints.

As companies work to overcome these obstacles, they must invest in advanced technologies, diversify suppliers, and create more resilient logistics networks.

Causes of Supply Chain Disruptions in 2025

The U.S. logistics industry continues to grapple with disruptions caused by:

- Global supply chain volatility: Geopolitical conflicts, trade restrictions, and international labor shortages contribute to unstable supply chains.

- Shortages of raw materials: Limited access to essential materials like semiconductors, metals, and chemicals affects manufacturing and supply operations.

- Unpredictable weather patterns: Natural disasters, hurricanes, and wildfires disrupt transportation routes, causing shipment delays.

- Port congestion: Overcrowding at major U.S. ports leads to increased shipping delays and higher freight costs.

- Limited warehouse capacity: A shortage of storage spaces, particularly in high-demand areas, creates bottlenecks in supply chain movement.

Impact on Businesses and Consumers

- Increased delays in product deliveries: Supply chain inefficiencies lead to longer waiting times for businesses and consumers.

- Higher operational costs: Increased expenses for shipping, storage, and inventory management put pressure on businesses.

- Consumer dissatisfaction: Delays and shortages lead to negative customer experiences and reduced brand loyalty.

- Stock shortages and overstock issues: Poor supply chain management results in either understocking or excessive inventory levels, impacting sales and profitability.

Solutions to Mitigate Supply Chain Risks

- Implementing AI-driven supply chain forecasting tools: Machine learning algorithms can predict demand fluctuations and optimize inventory levels.

- Strengthening supplier diversification strategies: Working with multiple suppliers reduces reliance on a single source and mitigates risks.

- Investing in localized production: Reducing dependency on foreign suppliers by establishing local manufacturing hubs enhances supply chain resilience.

- Enhancing real-time tracking and visibility: IoT-enabled devices help monitor shipments and identify disruptions in transit.

- Developing contingency plans: Businesses should have alternative logistics providers and emergency response strategies in place.

Key Strategies to Overcome Supply Chain Bottlenecks

| Challenge | Solution |

| Global conflicts | Strengthen domestic supply chains |

| Material shortages | Secure alternative suppliers |

| Weather disruptions | Implement predictive analytics |

| Port congestion | Diversify import/export routes |

| Warehouse capacity | Expand automated storage solutions |

2. Rising Transportation Costs

Rising transportation costs continue to challenge the logistics sector, impacting businesses and consumers alike.

Fuel prices, labor shortages, and regulatory changes all contribute to increased expenses, necessitating innovative cost-saving measures and strategic planning.

Key Factors Driving Up Costs

- Increasing fuel prices: Rising oil prices impact transportation costs for trucks, ships, and air cargo.

- Driver shortages: A declining workforce in the trucking industry leads to higher wages and operational expenses.

- Higher insurance rates: Rising insurance premiums due to increased accident risks and theft contribute to overall costs.

- Tighter government regulations: Stricter emissions standards and safety compliance requirements result in additional expenses.

Effects on Logistics Companies and Retailers

- Reduced profit margins: Logistics companies struggle with rising operational expenses.

- Higher prices for consumers: Increased transportation costs lead to more expensive goods.

- Increased competition: Small and mid-sized logistics firms face difficulties competing with larger, more efficient providers.

Cost-Saving Strategies

- Switching to electric and fuel-efficient vehicles: Companies investing in EV fleets benefit from lower fuel expenses.

- Utilizing route optimization software: AI-driven navigation tools reduce fuel consumption and improve efficiency.

- Enhancing warehouse automation: Robotics and AI-powered systems streamline inventory management and reduce labor costs.

- Collaborating with third-party logistics (3PL) providers: Outsourcing logistics to specialists helps companies reduce internal costs.

Cost-Effective Transport Solutions

| Strategy | Benefit |

| Electric vehicles | Lower fuel costs and emissions |

| Route optimization | Reduces mileage and fuel use |

| Warehouse automation | Cuts labor expenses |

| 3PL partnerships | Access to cost-efficient networks |

3. Labor Shortages and Workforce Challenges

Labor shortages continue to be a major issue for the U.S. logistics sector, particularly in trucking and warehouse operations.

A combination of an aging workforce, stringent regulations, and a lack of skilled professionals exacerbates the problem, forcing companies to seek innovative solutions.

Workforce Challenges and Solutions

| Challenge | Solution |

| Aging workforce | Implement training programs |

| Lack of new drivers | Improve job incentives |

| Automation resistance | Promote AI and robotics training |

The Ongoing Truck Driver Shortage

- Aging workforce leading to retirements

- Lack of interest from younger generations

- Stringent licensing requirements limiting new drivers

Demand for Skilled Logistics Professionals

- Need for tech-savvy professionals to manage automation

- Shortage of warehouse and logistics planners

- Increased demand for supply chain analysts

Automation and AI in Workforce Management

- Using AI-powered robots for warehouse operations

- Implementing self-driving trucks for long-haul deliveries

- Leveraging AI-based scheduling to optimize workforce productivity

4. Infrastructure Limitations and Aging Transport Networks

Aging infrastructure and inefficient transport networks are causing significant delays and increased costs for the logistics sector.

Poor road conditions, congested ports, and limited rail connectivity continue to be major concerns.

Addressing these challenges requires investment in modernization and smart logistics solutions.

Infrastructure Challenges and Solutions

| Challenge | Solution |

| Poor road conditions | Increased federal funding for repairs |

| Port congestion | Expansion of logistics hubs |

| Limited rail options | Investment in intermodal transport |

Impact of Outdated Infrastructure

- Poor road conditions causing delivery delays

- Congested ports slowing down imports and exports

- Limited railway and intermodal transport options

Government Initiatives and Investments

- Increased federal funding for highway repairs

- Expansion of railway networks to support freight transport

- Investment in smart logistics hubs and technology

5. Sustainability and Green Logistics Regulations

Regulatory changes in the logistics sector are introducing new compliance requirements, increasing operational costs, and pushing companies toward greener alternatives.

Stricter environmental policies, cross-border trade regulations, and evolving labor laws are reshaping logistics operations.

Key Regulatory Challenges and Compliance Strategies

| Regulatory Challenge | Compliance Strategy |

| Carbon emission regulations | Invest in electric and hybrid fleets |

| Stricter cross-border policies | Enhance documentation and tracking |

| Changing labor laws | Implement workforce training programs |

Stricter Environmental Laws

- Carbon emission reduction targets for logistics companies

- Implementation of eco-friendly packaging regulations

- Increased scrutiny on fuel consumption in transportation

Rise of Electric and Autonomous Freight Vehicles

- Growth of electric truck adoption by logistics providers

- Deployment of autonomous freight carriers to cut emissions

- Advancements in battery technology for long-haul shipping

Best Practices for Sustainable Logistics

- Using renewable energy sources in warehouses

- Implementing carbon offset programs

- Encouraging reverse logistics and recycling programs

6. Increasing Cybersecurity Threats

Cybersecurity threats are a growing concern in the logistics sector, with increasing digital integration exposing companies to potential cyber risks.

Data breaches, ransomware attacks, and IoT vulnerabilities pose significant challenges, making security a top priority.

Key Cybersecurity Threats and Preventive Measures

| Cyber Threat | Preventive Measure |

| Data breaches | Implement end-to-end encryption |

| Ransomware attacks | Regular system backups and updates |

| IoT vulnerabilities | Strengthen device authentication |

Why Logistics Companies Are Prime Targets

- Increased reliance on digital supply chain management

- Growing threat of ransomware attacks

- Vulnerability of IoT-enabled tracking systems

Major Cybersecurity Risks

- Data breaches leading to theft of sensitive shipment information

- Disruptions caused by malware attacks on fleet management software

- Hacking attempts on warehouse automation systems

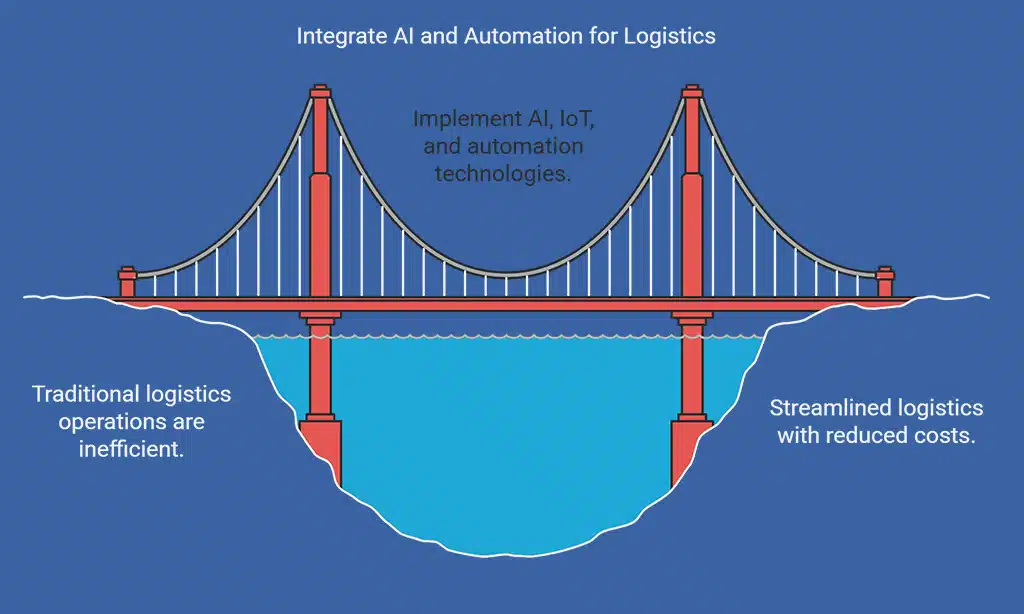

7. The Impact of AI, IoT, and Automation

The adoption of AI, IoT, and automation is reshaping logistics operations, optimizing efficiency, and reducing costs. Companies that fail to integrate these technologies risk falling behind competitors.

AI and Automation in Logistics

| Technology | Impact on Logistics |

| AI-driven routing | Optimizes fuel consumption |

| Robotics automation | Enhances warehouse efficiency |

| Predictive analytics | Improves inventory forecasting |

AI-Driven Route Optimization and Warehouse Automation

- AI-powered route planning reducing fuel consumption

- Robotic process automation improving warehouse efficiency

- AI-based demand forecasting enhancing inventory management

8. Changing Consumer Expectations and E-commerce Growth

The boom in e-commerce has led to increasing demands for faster, more efficient last-mile delivery, requiring logistics companies to adapt rapidly.

The pressure to meet customer expectations has increased the need for innovative delivery solutions and enhanced logistics infrastructure.

E-Commerce and Logistics

| Trend | Impact on Logistics |

| Same-day delivery | Requires micro-fulfillment centers |

| Gig economy drivers | Expands delivery workforce |

| Smart tracking | Enhances customer experience |

Growth of Last-Mile Delivery Demand

- Consumers demanding faster, same-day shipping

- Increased reliance on micro-fulfillment centers

- Expansion of gig economy delivery services

9. Regulatory and Compliance Complexities

Logistics companies must navigate an evolving regulatory landscape, including new federal and state laws that impact supply chain operations.

Stricter compliance measures demand increased transparency and reporting, adding administrative burdens on companies.

Additionally, varying state regulations create inconsistencies that complicate interstate logistics.

To remain compliant, businesses must invest in compliance management tools and establish dedicated regulatory teams.

Regulatory Challenges

| Regulation | Impact on Logistics |

| Cross-border policies | Delays in international shipments |

| Emission laws | Increases compliance costs |

| Labor regulations | Requires workforce restructuring |

Evolving Federal and State Regulations

- Stricter cross-border trade policies

- Compliance requirements for carbon emissions

- Evolving labor laws affecting logistics workers

10. The Geopolitical and Economic Landscape

Trade policies, inflation, and global conflicts significantly impact supply chains and logistics operations. Fluctuations in global trade agreements create uncertainty for businesses relying on international suppliers.

Additionally, economic downturns increase operational costs and reduce consumer demand, further straining logistics networks.

Geopolitical tensions can disrupt trade routes, causing delays and increasing transportation expenses.

Geopolitical and Economic Impacts

| Factor | Impact on Logistics |

| Trade tensions | Disrupts import/export flows |

| Inflation | Increases operational costs |

| Currency fluctuations | Affects global transactions |

Trade Policies and Global Conflicts Impacting Logistics

- U.S.-China trade tensions affecting imports

- War-driven supply chain disruptions

- Increased tariffs on essential raw materials

Effects of Inflation on Supply Chains

- Rising costs of raw materials and production

- Decreased consumer purchasing power

- Higher operational expenses for logistics companies

Strategies to Navigate Economic Uncertainties

- Diversifying supplier networks

- Strengthening risk management frameworks

- Leveraging economic forecasting tools

Takeaways

The top challenges facing the U.S. logistics sector in 2025 demand strategic planning, technological adaptation, and compliance with evolving regulations.

Logistics companies must embrace innovation, workforce training, and digital transformation to navigate these hurdles effectively.

By proactively addressing these challenges, businesses can enhance efficiency, reduce costs, and stay competitive in a rapidly changing logistics landscape.

Final Checklist for Overcoming Logistics Challenges Invest in AI and automation, Strengthen supply chain resilience, Adopt sustainable logistics solutions Enhance cybersecurity measures, Stay updated with regulatory compliance

By implementing these strategies, logistics companies can future-proof their operations and maintain a competitive edge in 2025 and beyond.