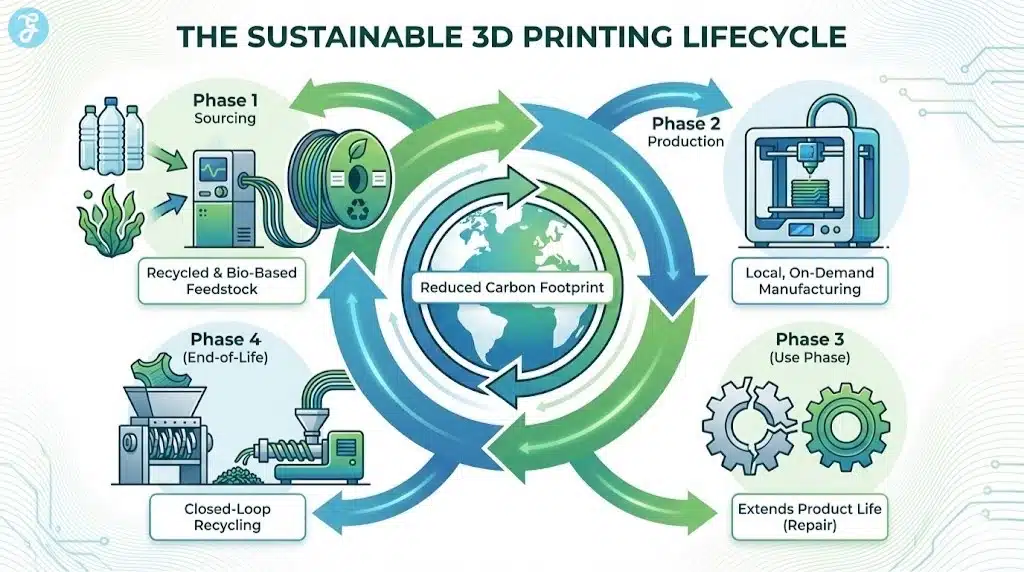

Sustainable 3D printing is changing how people think about manufacturing. Instead of producing thousands of identical items in distant factories and shipping them across the world, 3D printing can create parts on demand, closer to where they are needed. That shift can reduce waste, cut transport emissions, and make repair and customization easier. It can also do the opposite if it becomes a pipeline for disposable plastic trinkets and energy-heavy printing with no plan for reuse.

The truth sits in the middle. 3D printing is not automatically sustainable. It is a tool. Its environmental impact depends on materials, energy, failure rates, design choices, and end-of-life handling. When those pieces are managed well, sustainable 3D printing can deliver real climate benefits. When they are ignored, it can increase waste while looking futuristic.

This guide explains what makes 3D printing sustainable, how algae-based materials and recycled plastics fit into the future, where the biggest emissions and waste risks hide, and how individuals and businesses can build a genuinely greener printing workflow.

Why 3D Printing Can Be A Sustainability Breakthrough

Traditional manufacturing often relies on subtractive processes. You start with a block, cut away material, and throw scraps away. You also run large batch production because it is cheaper per unit, which creates inventory risk and overproduction.

3D printing, also called additive manufacturing, builds objects layer by layer. That changes the waste profile. In many cases, you use only what you need. You can also print replacement parts that extend the life of products, which can reduce the need for new manufacturing.

Sustainable 3D printing becomes especially powerful in three scenarios:

-

Printing parts to repair or upgrade existing products

-

Printing locally to reduce shipping and warehousing

-

Printing with lower-impact materials and closed-loop recycling

But those benefits are not guaranteed. They appear only when printing replaces a worse option, not when it creates additional consumption.

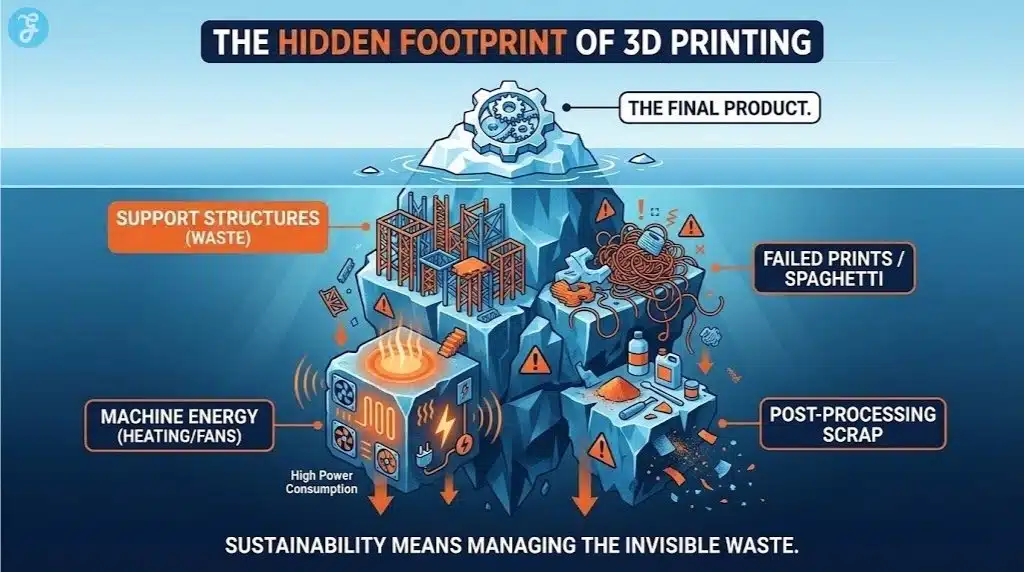

The Real Environmental Footprint Of 3D Printing

To judge sustainability, you need to understand where the footprint comes from. 3D printing impact usually comes from four areas:

-

Material production and sourcing

-

Printer energy use during printing and post-processing

-

Failure rates and support material waste

-

End-of-life handling of printed objects

An accurate evaluation compares 3D printing to the alternative. Printing a part that replaces an air-shipped spare can be beneficial. Printing a novelty item that will be thrown away in a week is not.

A Quick Footprint Table

| Footprint Area | What Drives It | Why It Matters |

|---|---|---|

| Materials | Virgin vs recycled, bio-based inputs | Often the biggest hidden impact |

| Energy | Print time, temperature, machine efficiency | Long prints can consume meaningful power |

| Waste | Supports, failed prints, trial iterations | Waste can exceed the final object mass |

| End-of-life | Recyclability, durability, take-back | Determines whether printing creates long-term waste |

Sustainable 3D printing focuses on reducing impact in each area, not only one.

Sustainable 3D Printing Starts With The Right Use Case

The most sustainable print is one that solves a real problem and avoids unnecessary replacement.

High-impact use cases include:

-

Repair parts for appliances, furniture, and tools

-

Custom fittings and adapters that extend product life

-

Medical and assistive devices customized for users

-

Prototypes that reduce waste in product development

-

On-demand manufacturing that reduces inventory and overproduction

Low-impact or negative-impact use cases include:

-

Disposable decorations and trends

-

Single-use plastic accessories with no reuse plan

-

Prints that replace cheap and durable mass-produced parts without benefit

-

High-failure printing workflows that waste more than they produce

Sustainable 3D printing is less about what the machine can do and more about what the object is for.

Recycled Plastic Filaments: The Backbone Of Greener Printing

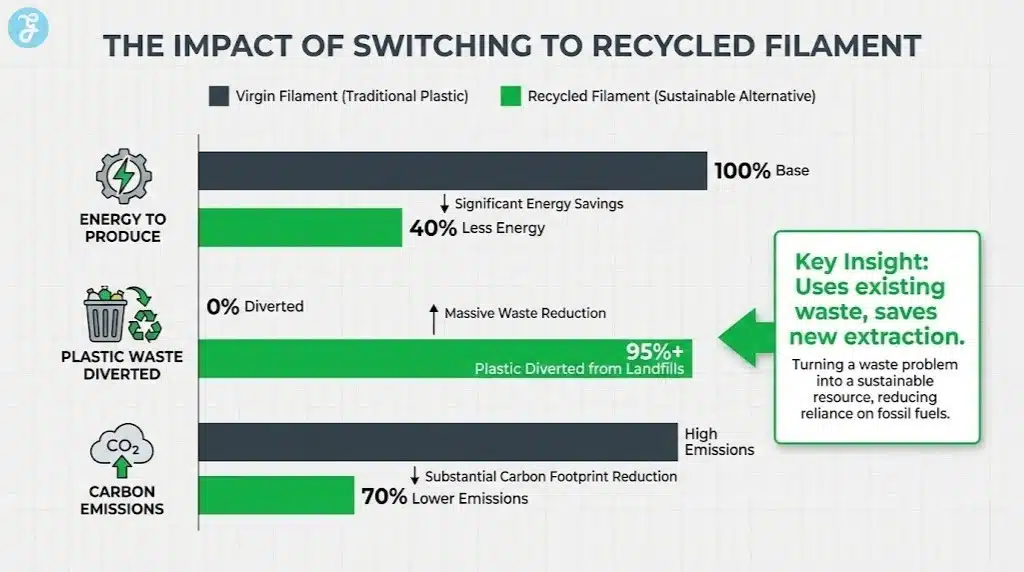

Recycled plastic filaments are one of the most practical pathways to lower-impact printing. They use plastic waste as feedstock, reducing demand for virgin polymers and keeping some plastics out of landfills.

The most common recycled filaments include recycled PLA, PETG, and sometimes blends that incorporate industrial scrap.

How Recycled Filament Is Made

A simplified process often includes:

-

Sorting and cleaning plastic feedstock

-

Shredding into flakes or pellets

-

Melting and extruding into filament

-

Cooling, spooling, and quality testing

The quality of recycled filament depends heavily on sorting, contamination control, and consistent extrusion. Poorly controlled recycling can produce filament that clogs nozzles, prints inconsistently, and increases failure rates, which undermines sustainability.

Recycled Filament Pros And Cons

| Benefit | Why It Helps | Common Risk |

|---|---|---|

| Lower virgin plastic demand | Reduces fossil-based production | Blends may reduce recyclability |

| Waste diversion | Keeps material in use longer | Contamination can weaken prints |

| Potentially lower cost | Can be cheaper at scale | Inconsistent diameter causes failures |

| Strong storytelling | Clear sustainability narrative | Marketing may exaggerate content |

A key principle is simple. If recycled filament increases your failure rate, it can erase the environmental benefit. Quality matters as much as content.

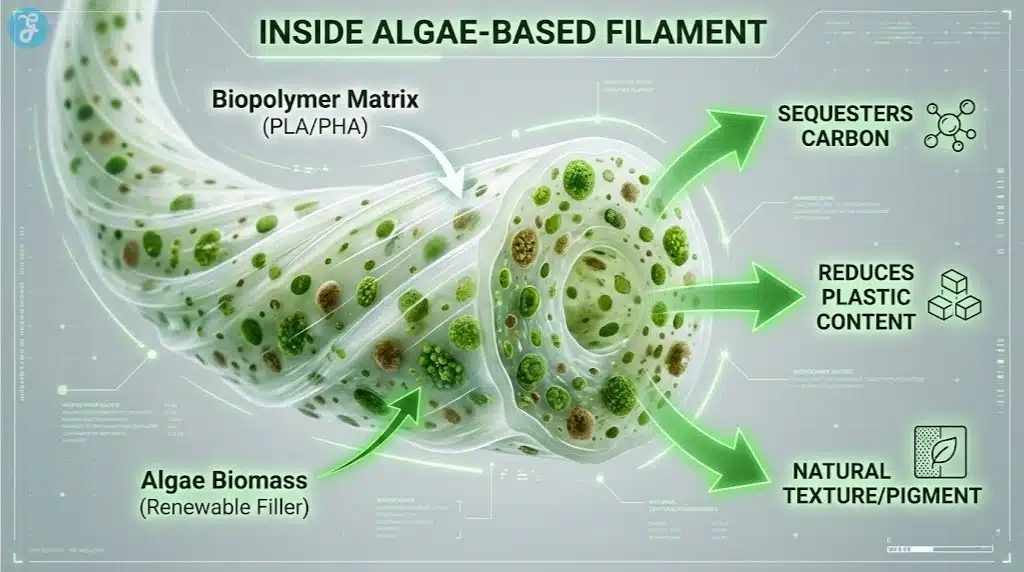

Algae-Based Materials: Why They Matter And Where They Fit

Algae-based materials are attracting attention because algae can grow quickly, does not require farmland in the same way as crops, and can be cultivated with different resource inputs. Algae can also be used in composites, pigments, and bio-based polymers.

In 3D printing, algae is usually used as an additive or filler in composite filaments rather than a pure structural plastic. The promise is reduced fossil content and a shift toward renewable feedstocks.

How Algae Enters 3D Printing Materials

Common approaches include:

-

Blending algae-based biomass into a polymer matrix

-

Using algae-derived oils or compounds in bio-based plastics

-

Using algae as a pigment or functional additive

Where Algae-Based Filaments Make Sense

Algae-based filaments tend to fit best in:

-

Decorative objects where structural strength is not critical

-

Prototypes where sustainability and texture matter

-

Low-load parts that do not face heat or mechanical stress

A major challenge is performance consistency. If algae composites reduce strength or increase brittleness, durability can fall. Durability is sustainability because it determines how long the object stays useful.

Algae Filaments Versus Conventional Filaments

| Attribute | Algae-Based Composite | Conventional PLA/PETG |

|---|---|---|

| Fossil content | Often lower | Varies, often higher |

| Printability | Can be good, depends on formulation | Generally predictable |

| Strength | Often lower than pure polymers | Often higher and consistent |

| Sustainability potential | Strong if durable and scalable | Depends on virgin vs recycled sources |

| End-of-life | Complex due to composite mix | Still challenging, but more standard |

Algae-based materials can support sustainable 3D printing, but they must be assessed honestly. Not all algae filaments are greener in practice.

Energy Use: The Hidden Cost Of Long Prints

Energy use is one of the easiest impacts to overlook because it happens quietly during printing. A printer can run for hours or days, especially on large objects or high-resolution prints.

Energy drivers include:

-

Nozzle and bed temperature

-

Print duration and speed

-

Enclosure heating for certain materials

-

Post-processing tools and curing stations

The sustainability goal is not always to minimize energy at any cost. It is to reduce waste and improve efficiency while still producing a durable object.

Energy Reduction Strategies That Do Not Hurt Quality

-

Use the lowest temperature that prints reliably

-

Reduce unnecessary high-resolution settings

-

Optimize infill and shell thickness for strength-to-material ratio

-

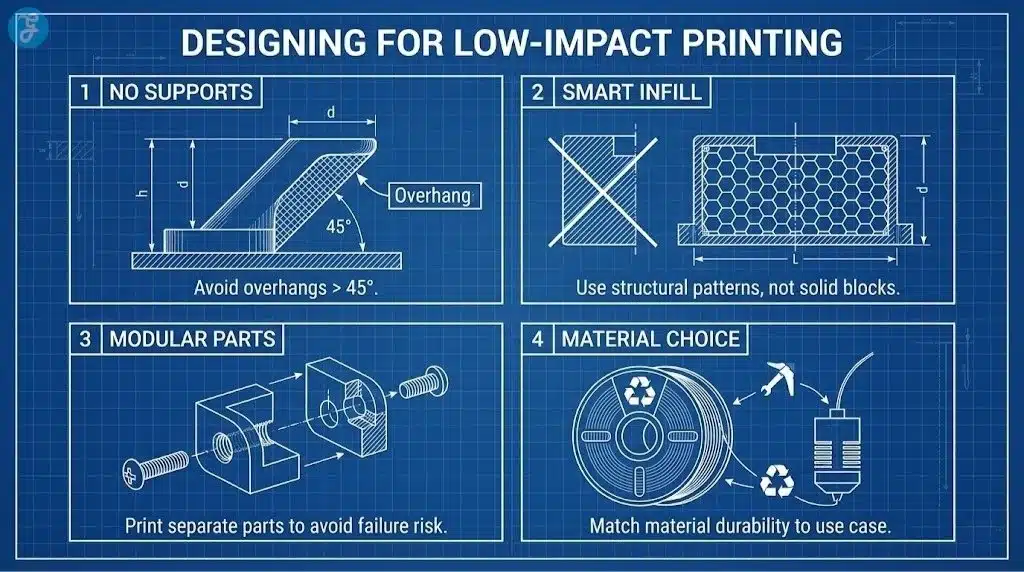

Avoid printing supports through smart orientation and design

-

Print multiple small parts in one job when it reduces warm-up cycles

Support Material And Failed Prints: The Real Waste Problem

Many sustainability discussions focus on filament content. But in real printing workflows, waste often comes from supports, rafts, brims, and failed prints.

A print that fails at hour eight can waste almost as much energy and material as a successful print. A design that requires heavy supports can waste a large portion of material even when it succeeds.

How To Reduce Print Waste

-

Design for support-free printing when possible

-

Use chamfers and angles that print cleanly

-

Break complex objects into parts that print without supports

-

Use test prints for critical features rather than full objects

-

Maintain printers to reduce clogging and failures

Waste Reduction Table

| Waste Source | Why It Happens | Best Fix |

|---|---|---|

| Supports | Overhangs and complex geometry | Change orientation, redesign geometry |

| Failed prints | Poor calibration, inconsistent filament | Calibrate, use quality filament, maintain printer |

| Excess infill | Overbuilding for strength | Use strength-driven infill strategy |

| Rafts and brims | Adhesion issues | Improve bed leveling and surface prep |

| Iteration waste | Poor prototyping discipline | Use smaller test pieces first |

Sustainable 3D printing is often more about process discipline than new materials.

Designing For Durability: The Sustainability Multiplier

If a printed object breaks quickly, you may print it again. That doubles material and energy use. Durability is the multiplier that determines whether 3D printing reduces or increases footprint.

Durability depends on:

-

Material selection and suitability

-

Print settings like layer height, temperature, and cooling

-

Part orientation relative to stress forces

-

Wall thickness and mechanical design features

A strong sustainable workflow prints fewer objects that last longer.

Durability Best Practices

-

Orient parts so layers resist expected stress

-

Use fillets to reduce stress concentration

-

Avoid thin walls for load-bearing parts

-

Use mechanical fasteners where replacement is needed

-

Select materials based on heat and UV exposure needs

Closed-Loop Printing: The Circular Economy In A Workshop

Closed-loop printing aims to recycle failed prints and scrap into new filament. This is appealing because it reduces waste and can lower costs.

But closed-loop printing has challenges:

-

Material contamination can reduce filament quality

-

Different plastics are hard to blend safely

-

Reprocessing can degrade polymer strength over cycles

-

Equipment costs can be high for consistent filament

Still, in controlled environments such as schools, labs, and maker spaces, closed-loop systems can work well when plastics are sorted correctly and quality control is enforced.

Closed-Loop Workflow Table

| Step | What Happens | What Can Go Wrong |

|---|---|---|

| Sorting | Separate PLA, PETG, others | Mixing materials causes weak filament |

| Cleaning | Remove labels, dust, contaminants | Contamination causes clogs and defects |

| Shredding | Turn scrap into flakes | Irregular flakes can jam extruders |

| Extrusion | Melt and form filament | Inconsistent diameter causes failures |

| Testing | Print test pieces for calibration | Skipping testing increases waste later |

Closed-loop printing is one of the most direct expressions of sustainable 3D printing, but it requires strict discipline.

Material Selection: When “Green” Filament Is Not The Greenest Choice

Sustainable 3D printing improves when material choices match real-world use. A common mistake is choosing a “green” filament for a part that needs heat resistance, outdoor durability, or mechanical strength. When that part fails, breaks, or warps, you reprint it. That doubles material use and electricity, and it often creates more waste than choosing a more durable option from the start.

For example, a recycled filament that prints inconsistently can increase failure rates. Each failed print wastes not only plastic but also hours of energy. In that case, a slightly higher-impact filament that prints reliably and lasts longer can be the better sustainability decision overall. The best approach is to treat sustainability as a lifecycle problem, not a label problem.

Here are practical material questions that support sustainable outcomes:

-

Will the part be exposed to heat, sunlight, or water?

-

Does it carry load or experience repeated stress?

-

Does it need flexibility or impact resistance?

-

Can it be repaired, or will it be replaced when it fails?

-

How many times do you expect to print this part over its lifespan?

Design For Less Plastic Without Losing Strength

Many prints are heavier than they need to be because people rely on high infill percentages instead of smarter geometry. In sustainable 3D printing, reducing material while maintaining strength is one of the best ways to cut impact.

Instead of increasing infill, consider:

-

Thicker outer walls with moderate infill

-

Ribbing and internal supports built into the design

-

Fillets at corners to reduce cracking

-

Reinforced screw holes and stress points

-

Splitting parts to print in stronger orientations

This approach reduces both print time and filament use. It also improves durability, which matters more than small improvements in filament sourcing.

Post-Processing: The Hidden Sustainability Cost

Post-processing can quietly add waste and energy. Sanding, chemical smoothing, painting, and coatings can improve appearance and performance, but they can also add materials that complicate recycling and increase environmental burden.

A sustainable workflow treats post-processing as purposeful:

-

Use post-processing only when it improves lifespan or safety

-

Prefer mechanical finishing over chemical methods when possible

-

Avoid thick coatings unless they are required for durability

-

Choose finishes that can be repaired rather than replaced

If the finish helps the part last longer, it may be worth the tradeoff. If it exists only for appearance and short-term novelty, it often reduces sustainability.

Print Farms And Business Operations: How To Keep Scale Green

As printing scales, efficiency becomes more important than individual print choices. Print farms and businesses can reduce impact by managing energy and quality control.

High-impact operational improvements include:

-

Scheduling prints during lower-carbon grid hours where possible

-

Using printers with better insulation and stable temperature control

-

Standardizing materials to reduce contamination and failed jobs

-

Maintaining nozzles, belts, and beds to prevent repeated errors

-

Creating print profiles that balance speed, strength, and waste

Sustainable 3D printing at business scale is about consistency. When failure rates drop and quality rises, material and energy waste fall naturally.

Sustainable 3D Printing In Construction And Industry

Large-scale additive manufacturing is expanding into construction, aerospace, automotive, and industrial parts. In these areas, sustainability benefits can be significant because traditional manufacturing can be wasteful.

Potential benefits include:

-

Reduced scrap in metal and composite manufacturing

-

Lightweight parts that reduce fuel or energy use in transport

-

On-demand spare parts that reduce inventory and shipping

-

Faster prototyping cycles that reduce material waste in development

But industrial printing can also consume large energy, especially in metal printing processes. Sustainability depends on the energy source, process efficiency, and whether the printed part reduces overall lifecycle emissions.

How To Evaluate A Sustainable 3D Printing Claim

Many brands and projects use “eco” language. A simple evaluation framework helps you avoid vague claims.

The Practical Evaluation Checklist

-

Is the filament truly recycled or bio-based, and what percentage?

-

Does it print reliably, or does it increase failures?

-

Does the final product last long enough to justify the process?

-

Can the material be recycled again, or is it a mixed composite?

-

Does printing replace a worse alternative, or create extra consumption?

Scorecard Table

| Factor | What Good Looks Like | Red Flag |

|---|---|---|

| Material sourcing | Verified recycled content | Vague “eco” claims |

| Print reliability | Low failure rate | Frequent clogs and defects |

| Durability | Long service life | Breaks and reprints |

| End-of-life | Clear pathway or reuse | No realistic disposal plan |

| Use case | Repair, replacement, functional value | Disposable novelty |

This approach keeps sustainable 3D printing grounded in outcomes.

How Sustainable 3D Printing Fits The Green Tech Revolution

The Green Tech Revolution is about eco-innovation reshaping digital and physical life. 3D printing connects to that because it changes how products are made, shipped, repaired, and replaced.

It supports green innovation when it:

-

Extends product lifespans through repair parts

-

Reduces overproduction through on-demand manufacturing

-

Uses recycled or renewable materials responsibly

-

Encourages circular behavior through reuse and closed-loop systems

In the best case, sustainable 3D printing shifts manufacturing from wasteful mass production to smarter localized production with longer-lasting products.

Final Thoughts

Sustainable 3D printing can reduce waste, cut transport emissions, and support a more circular economy. But it only delivers those benefits when materials, energy use, process discipline, and durability are taken seriously.

Recycled plastics are the most practical pathway today, but they must be high quality to avoid increasing failures. Algae-based composites are promising, especially as renewable feedstocks improve, but performance and finishing determine whether they truly reduce impact. The biggest sustainability gains often come from better design, fewer supports, fewer failed prints, and printing parts that extend the life of existing products.

If you treat 3D printing as a tool for durability and repair instead of novelty and excess, sustainable 3D printing becomes more than a cool technology. It becomes a real building block for a lower-waste future.