In the hyper-competitive world of global commerce, speed is the baseline for survival. For logistics managers, the challenge isn’t just about moving freight from point A to point B; it’s about navigating a global supply chain that is increasingly prone to volatility, from port congestion to sudden regulatory shifts.

When a shipping delay occurs, the consequences ripple outward, resulting in ghost inventory, depleted margins, and the dreaded “where is my order?” calls from frustrated clients.

Therefore, avoiding these bottlenecks requires a shift from reactive troubleshooting to a high-velocity strategy that prioritizes foresight and digital precision. By implementing the right technological and operational safeguards, you can transform your logistics from a potential liability into a streamlined engine of growth.

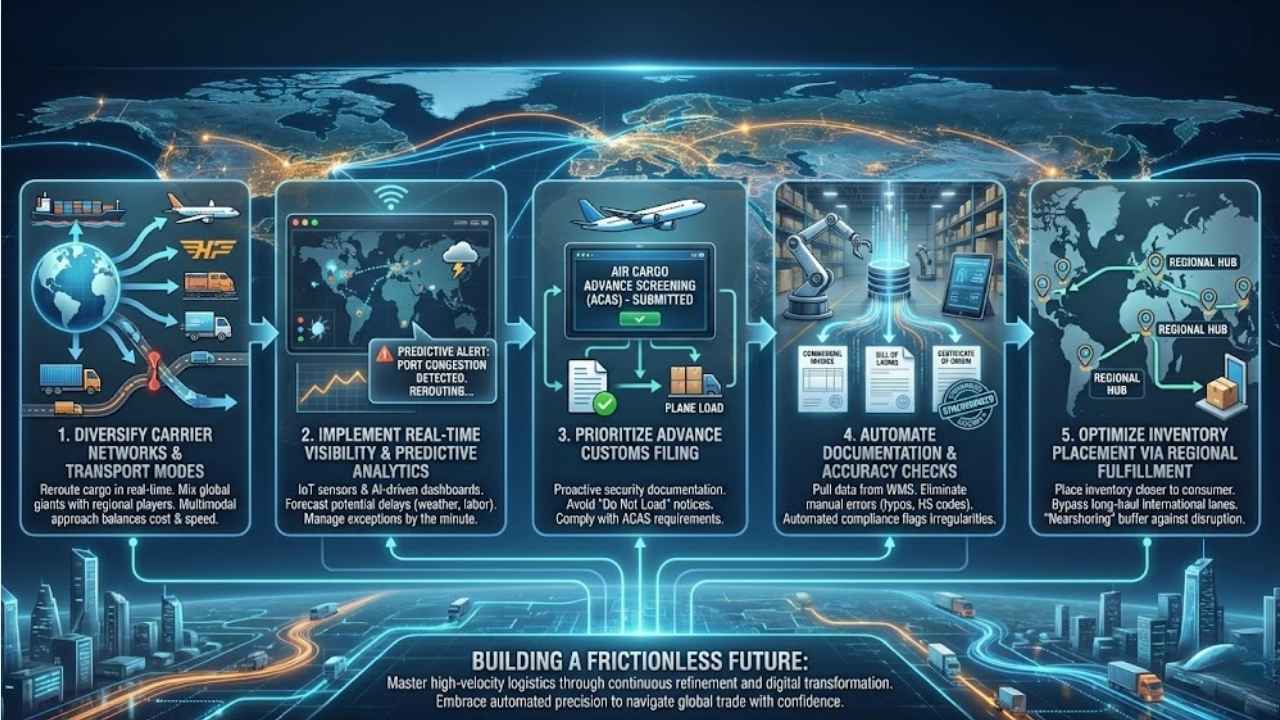

How to Deal with Shipping Delays: 5 Strategies

Diversify Carrier Networks and Transportation Modes

One of the most effective ways to build resilience into your supply chain is to move away from a single-thread logistics model.

Relying on one carrier or a single transport lane leaves your business vulnerable to delays from localized strikes, weather disruptions, or regional capacity crunches.

Instead, by diversifying your carrier partnerships – mixing global giants with specialized regional players – you gain the flexibility to reroute cargo in real-time when a lane becomes congested.

Furthermore, adopting a multimodal approach, such as combining sea and air freight for high-value components, allows you to balance cost and speed.

Overall, treat your carrier network like a diversified investment portfolio to ensure that a single point of failure never brings your entire operation to a standstill.

Implement Real-Time Visibility and Predictive Analytics

You cannot fix what you cannot see. In a traditional logistics setup, tracking often involves looking at where a package was twelve hours ago, rather than where it is now. However, modern logistics demand real-time visibility powered by IoT sensors and AI-driven dashboards.

These tools do more than just show a dot on a map; they use predictive analytics to forecast potential cargo delays before they happen. For example, if an AI system detects a building storm or a labor dispute at a destination port, it can alert your team to reroute the shipment or adjust delivery expectations immediately.

This proactive stance allows you to manage exceptions by the minute, turning potential crises into manageable minor adjustments.

Prioritize Advance Customs Filing

In the realm of air freight, the margin for error is razor-thin. Because air shipments move at such high speeds, any delay at the border can instantly negate the premium price paid for rapid transport. Therefore, proactive and timely security documentation is essential.

For instance, when shipping into the US, ensure advance filing for customs air cargo to comply with the Air Cargo Advance Screening (ACAS) requirements. By utilizing specialized software for this process, you can ensure your shipment information is submitted well before the plane is loaded, avoiding “Do Not Load” notices that can ground your freight and derail your entire distribution schedule.

Automate Documentation and Accuracy Checks

Manual data entry is the silent killer of shipping efficiency. A simple typo on a commercial invoice or a mismatched HS code can trigger an intensive customs examination, leading to significant shipping delays and unexpected storage fees.

As such, high-velocity logistics rely on automated document generation that pulls data directly from your warehouse management system. This ensures that every piece of paperwork, from the bill of lading to the certificate of origin, is perfectly synchronized.

Furthermore, implementing automated compliance checks allows your system to flag irregularities or missing signatures before the shipment leaves the warehouse. In a world where customs compliance is increasingly digitized, human error is an avoidable risk that no modern business should be willing to take.

Optimize Inventory Placement via Regional Fulfillment

Sometimes, the best way to avoid a shipping delay is to reduce the distance the goods have to travel. Regionalization is a growing trend for a reason: it places inventory closer to the end consumer, bypassing long-haul international lanes that are most susceptible to disruption.

By utilizing regional fulfillment centers or bonded warehouses, you can stage goods near major travel hubs in advance. This “nearshoring” of inventory provides a critical buffer against global freight volatility. When a disruption hits a major international lane, your regional stock allows you to continue fulfilling orders without interruption, keeping your customer experience consistent even when global logistics are in flux.

Building a Frictionless Future

Mastering high-velocity logistics is a journey of continuous refinement rather than a one-time fix. As trade regulations grow more complex and customer expectations for speed continue to rise, the businesses that thrive will be those that embrace digital transformation at every level of their supply chain.

From diversifying carrier networks to ensuring precise security filings, each strategy is a building block for a more resilient operation. By replacing manual uncertainty with automated precision, you can navigate the global trade landscape with confidence, ensuring your goods move at the speed of your ambitions.