Lab-grown materials are changing what luxury means. For decades, “premium” was linked to rarity, extraction, and traditional supply chains. Diamonds came from mining. Leather came from livestock. Exotic skins came with ethical and environmental controversy. Today, a different kind of prestige is emerging, driven by science and manufacturing control. In this shift, luxury becomes less about where something was taken from and more about how intelligently it was made.

This is not just a branding story. It is a technology story. Lab-grown diamonds are real diamonds, created through controlled processes that mimic natural formation. Biofabricated leather can be grown from fungal structures, plant-based composites, or lab-cultured proteins. These innovations aim to cut cruelty, reduce land and water pressure, and improve traceability.

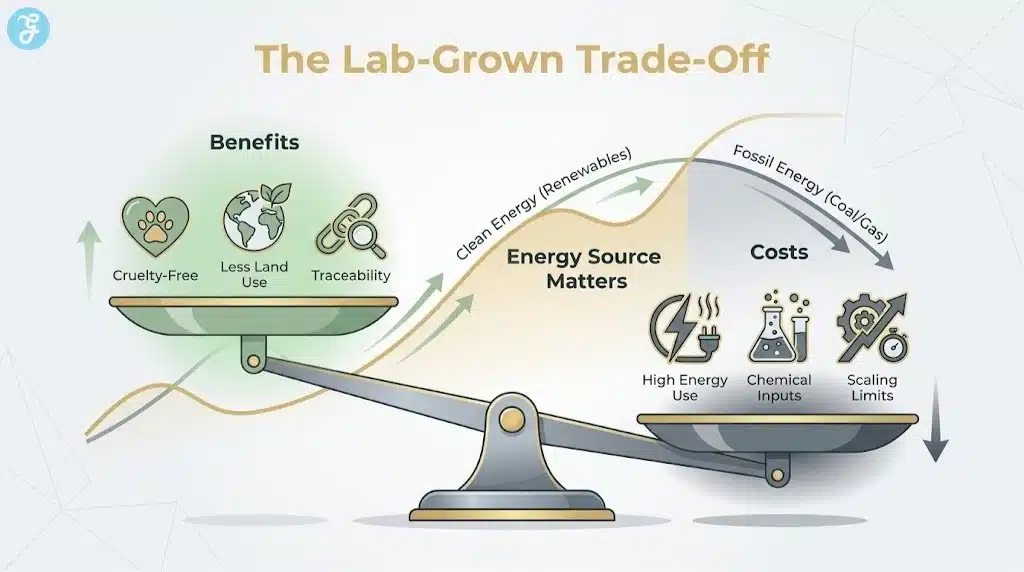

Still, lab-grown does not automatically mean sustainable. The climate footprint depends on inputs, especially energy. The ethical impact depends on labor practices and transparency. And the consumer value depends on durability, repairability, and end-of-life reality.

This cluster guide explains how lab-grown materials are made, where they outperform conventional materials, where they fall short, and how to judge “cruelty-free luxury” without falling for hype.

Why Luxury Is Moving Toward Lab-Grown Materials

Luxury markets follow culture as much as craftsmanship. In the last decade, consumers have become more aware of supply chains. They care about labor, animal welfare, and environmental pressure. They also expect brands to prove claims rather than rely on vague storytelling.

Lab-grown materials appeal to this new reality because they offer controlled production and more consistent traceability than many extractive supply chains. They also allow brands to experiment with performance, texture, and aesthetics in ways that traditional materials cannot always match.

Key forces accelerating adoption include:

- Pressure to reduce cruelty and controversial sourcing

- Demand for traceable, documented supply chains

- Social media scrutiny that punishes vague sustainability claims

- Rapid innovation in biotech, fermentation, and advanced manufacturing

- Consumer willingness to pay for “clean” prestige when quality holds up

Luxury also values narrative. “Grown, not mined” and “crafted without animals” are powerful stories. The challenge is making sure the story matches the data.

What “Lab-Grown” Actually Means

The phrase “lab-grown” gets used loosely. In practice, lab-grown materials fall into a few main categories.

Lab-Grown Mineral Materials

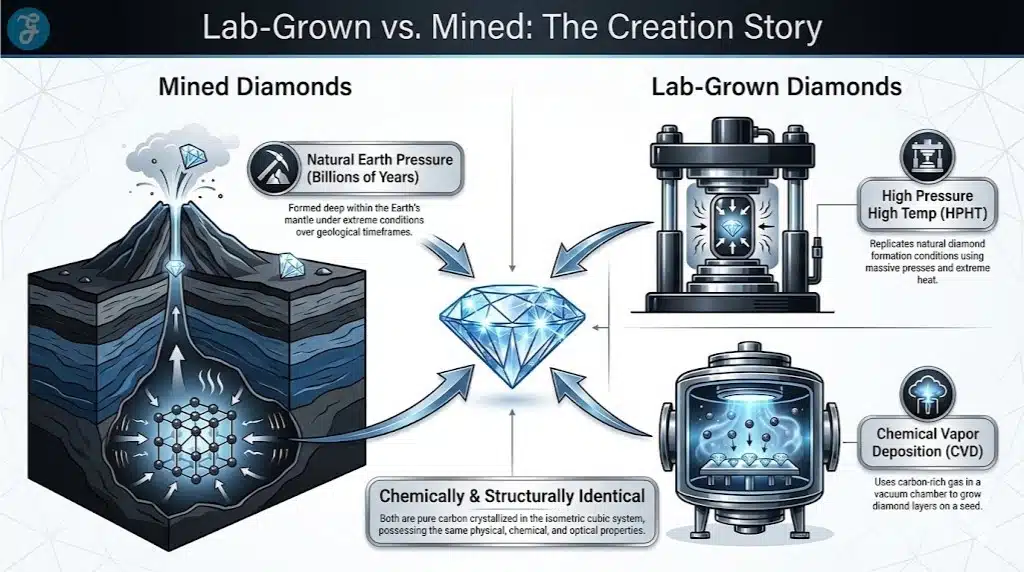

These are materials grown through controlled physical processes. Lab-grown diamonds are the clearest example. They are not imitations. They are the same crystal structure as mined diamonds.

Biofabricated Materials

These are materials produced through biological processes. The material may be grown from fungi, bacteria, yeast, plant cellulose, or lab-cultured proteins. The goal is to create leather-like or textile-like materials without animals.

Plant-Based Composite Materials

Some materials are not lab-grown in a strict sense, but they are engineered. They blend plant fibers, bio-based polymers, and coatings to mimic leather or create new alternatives.

A Simple Lab-Grown Materials Map

| Category | What It Includes | What Makes It Different |

| Lab-grown minerals | Diamonds, gemstones | Physical growth under controlled conditions |

| Biofabricated textiles | Mycelium leather, cultured proteins | Biological production with engineered properties |

| Plant-based composites | Pineapple fiber, cactus blends, cellulose composites | Engineered from plant sources, often with coatings |

| Hybrid materials | Bio-based core with synthetic finish | Performance tuning, but end-of-life can be complex |

Understanding the category matters because claims and impacts vary widely.

Lab-Grown Diamonds: How They Are Made

Lab-grown diamonds are produced mainly through two methods. Both create real diamonds.

HPHT: High Pressure High Temperature

HPHT mimics the natural diamond formation environment by applying extreme pressure and high temperature to carbon sources. In controlled systems, carbon crystallizes into diamond structures.

Key traits of HPHT include:

- Diamond growth that can be efficient at scale

- Potential for different color outcomes depending on conditions

- Strong industrial track record in specialized applications

CVD: Chemical Vapor Deposition

CVD uses a carbon-rich gas in a chamber where carbon atoms deposit onto a diamond seed, building the crystal layer by layer. This method is common in jewelry-grade production.

Key traits of CVD include:

- High control over growth

- Strong consistency for certain grades

- A process that depends heavily on electricity and system efficiency

The Practical Difference For Buyers

Most buyers do not need to choose between HPHT and CVD directly. What matters is grading, quality, and the producer’s energy source. Still, knowing the methods helps you ask better questions about carbon footprint and transparency.

Are Lab-Grown Diamonds More Sustainable Than Mined Diamonds

The sustainability question depends on what you measure and how you measure it. Mining has land disturbance, water use, and supply chain complexity. Lab growth has energy use and industrial inputs.

Lab-grown diamonds can reduce certain impacts related to mining, but they can also be energy-intensive. If production relies on fossil-heavy electricity, the footprint can be significant.

The most meaningful sustainability signals often include:

- Energy source for production

- Manufacturing efficiency and yield

- Supply chain transparency and reporting

- Waste handling and byproducts

The best claim is not “lab-grown is always greener.” The best claim is “this specific producer uses clean energy and can prove lower impact.”

The Rise Of Biofabricated Leather

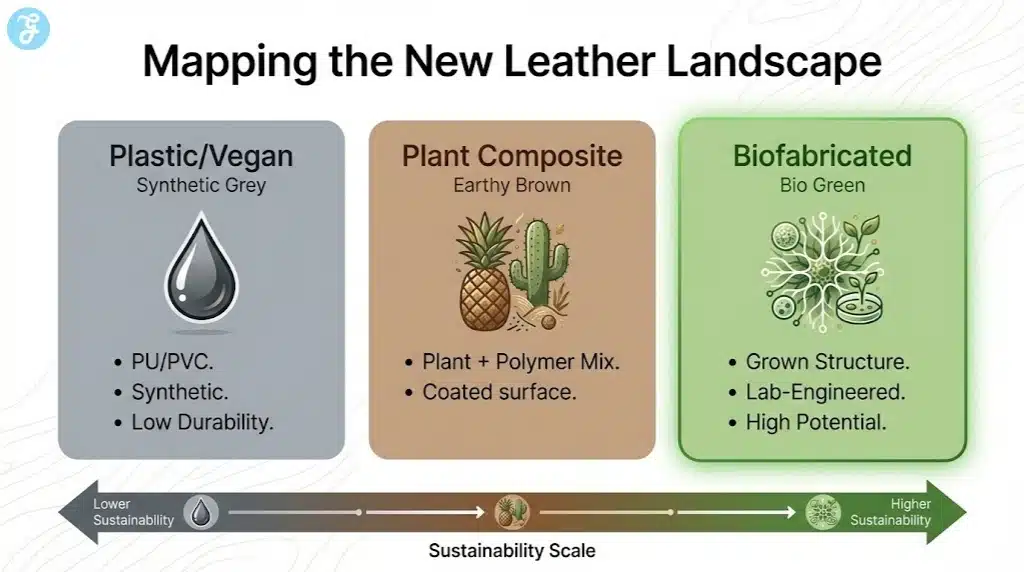

Leather alternatives have grown rapidly. But the category is messy. Some products marketed as “vegan leather” are petroleum-based plastics. Those can reduce animal cruelty, but they often create microplastic and end-of-life issues.

Biofabricated leather aims to offer a different path. Instead of plastic imitation, it tries to create a material with leather-like feel and durability, grown through biological systems.

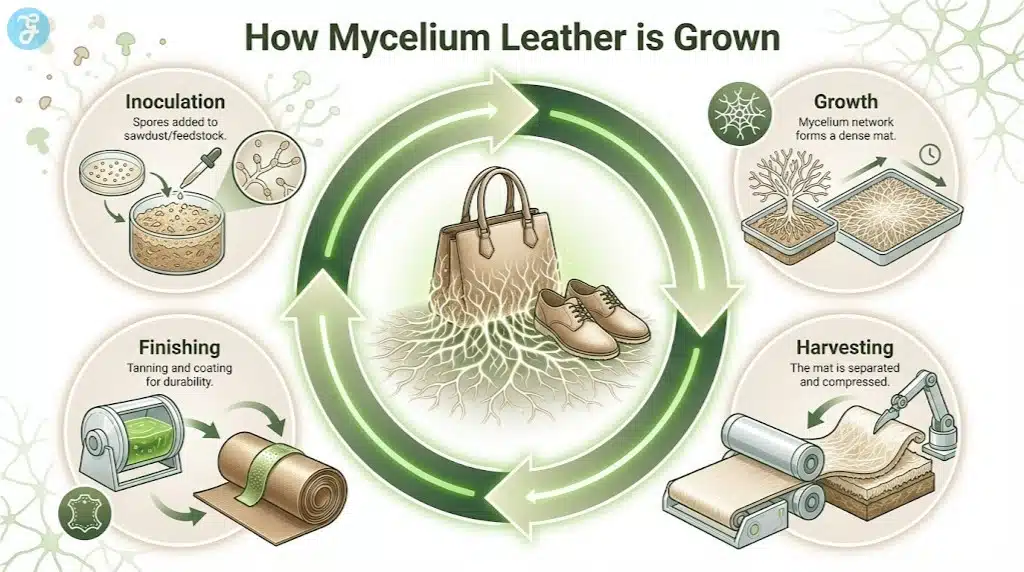

Mycelium Leather

Mycelium is the root-like structure of fungi. It can be grown into mats and then processed into leather-like sheets. The process can be shaped in controlled environments, potentially reducing waste.

Strengths often include:

- Rapid growth cycles compared to livestock

- Potential for lower land use

- Tunable texture and thickness

Challenges often include:

- Coatings and binders that can affect biodegradability

- Durability compared to high-grade animal leather

- Scaling consistency for luxury production

Cultured Protein Leather

Some companies work on growing collagen or similar proteins through fermentation or cell culture. The idea is to produce material closer to the underlying biology of leather, without raising animals.

This approach is still developing, and it can involve complex bioprocessing, which may require energy and specialized inputs.

Plant-Based Leather Alternatives

Plant-based alternatives often use fibers or pulp from sources like pineapple leaves or cactus. These products can reduce animal use, but many still rely on synthetic coatings for durability and water resistance.

That means the sustainability story depends on:

- Percentage of bio-based content

- Type and thickness of coatings

- Product durability and repairability

- End-of-life options

A Reality Check: Vegan Leather Vs Biofabricated Leather

“Vegan leather” is a broad label. It can refer to:

- Plastic-based polyurethane materials

- Plant-fiber composites with synthetic coatings

- Mycelium-based materials

- Fermentation-based or cultured protein materials

Consumers often assume vegan equals sustainable, but that is not always true. The better approach is to evaluate the full system: inputs, durability, and disposal.

A Comparison Table For Buyers

| Material Type | Animal-Free | Durability Potential | End-Of-Life Reality |

| PU-based vegan leather | Yes | Medium | Often not biodegradable, recycling limited |

| Plant composite with coating | Yes | Medium | Coating may limit composting or recycling |

| Mycelium-based | Yes | Emerging | Depends heavily on finish and binder choices |

| Cultured protein | Yes | Promising | Depends on scale, inputs, and processing |

This is where lab-grown materials become a meaningful conversation. The value is not the label. The value is the engineering and transparency behind the product.

Why Lab-Grown Materials Matter For The Environment

The environmental promise of lab-grown materials comes from a few possible gains.

Land And Water Pressure

Livestock and mining can have high land impacts. If biofabrication and controlled growth reduce land use, that can relieve pressure on ecosystems.

Supply Chain Control And Traceability

Controlled production can be easier to document. That can reduce unethical labor risks and increase accountability.

Potential Waste Reduction

Some biofabrication processes can produce material closer to the final shape, reducing cut-and-sew waste.

Still, not all lab-grown materials deliver these benefits automatically. The real test is lifecycle analysis, not marketing.

The Energy Problem: The Hidden Tradeoff

Many lab-grown processes require electricity, heating, cooling, and controlled environments. This is especially true for lab-grown diamonds and certain fermentation-based materials.

If the energy is fossil-heavy, sustainability gains shrink. If the energy is clean, lab-grown materials can become much more competitive in footprint.

This is why buyers and journalists should ask:

- What energy sources power production?

- Are there audited footprint reports?

- Does the company report scope 1, 2, and relevant scope 3 emissions?

- Does the company disclose yields and waste rates?

At this point in the article, the focus keyword matters again because it frames the whole analysis: lab-grown materials are only as sustainable as the systems that produce them.

Durability Is The Most Underrated Sustainability Metric In Luxury

Luxury items become sustainable when they last. A durable bag used for ten years can outperform a “greener” bag that falls apart in two.

This is why durability and repairability are central to evaluating lab-grown materials. If a material cracks, peels, or weakens quickly, the product may be replaced more often, which increases total footprint.

Durability Questions To Ask

- Does the material resist cracking and peeling?

- How does it handle water, heat, and abrasion?

- Can it be repaired, reconditioned, or refinished?

- Does the brand offer repair services?

- Does the product age well, or does it degrade?

Some alternatives perform best in specific products. A mycelium material might be great for accessories but not yet ideal for high-stress footwear. Context matters.

How Brands Use Lab-Grown Materials In Products Today

Lab-grown materials are already appearing across categories:

- Jewelry with lab-grown diamonds

- Handbags and accessories with mycelium-based panels

- Shoes using plant-based composites

- Watches and fashion items using engineered leather alternatives

The role of these materials varies. Some are used as full replacements. Others are used as partial components combined with traditional materials. This can improve performance, but it can also make recycling harder.

Greenwashing Risks In Cruelty-Free Luxury

This market attracts strong storytelling. That creates risk.

Common greenwashing patterns include:

- Using “vegan leather” to hide plastic-heavy materials

- Promoting lab-grown diamonds as automatically carbon-neutral without proof

- Highlighting one sustainable input while ignoring energy use

- Claiming biodegradability while using heavy synthetic coatings

- Using vague claims like “eco-friendly” without measurable data

A credible brand should be able to explain materials, inputs, and tradeoffs clearly.

A Practical Buyer Scorecard For Lab-Grown Materials

You do not need a scientific background to make smarter decisions. You need a consistent scorecard.

The Simple Scorecard

- Transparency: does the brand explain materials and processes clearly?

- Energy: does the producer use clean electricity and disclose it?

- Durability: will the item last and age well?

- Repair: can it be repaired or refinished?

- End-of-life: is there a return program or realistic disposal path?

Scorecard Table

| Factor | What To Look For | Red Flag |

| Transparency | Clear material breakdown and sourcing | Vague “eco” language |

| Energy disclosure | Renewable use and footprint reporting | No mention of energy inputs |

| Durability | Strong wear performance and warranties | Peeling, cracking, short lifespan |

| Repair services | Repair program or guidance | No repair support |

| End-of-life | Take-back or recycling pathway | “Just recycle it” with no detail |

This approach helps you evaluate lab-grown materials with fewer assumptions and less hype.

How Lab-Grown Materials Are Manufactured At Scale

Scaling is where many promising materials stumble. A small batch can look perfect. Large-volume production reveals variability, defects, and finishing challenges. Luxury also expects consistency, so scaling must protect quality.

For lab-grown diamonds, scaling depends on reactor capacity, energy cost, and yield. For biofabricated materials, scaling depends on growth speed, contamination control, and processing consistency.

Key scale questions include:

- How long does production take per unit area or per stone?

- What is the defect rate, and what happens to rejects?

- What chemicals, binders, and coatings are required?

- Can the process run reliably across facilities, not just one flagship plant?

Scale Reality Table

| Material Type | Scaling Constraint | What “Good” Looks Like |

| Lab-grown diamonds | Reactor throughput and electricity cost | Higher yield with clean power |

| Mycelium materials | Uniform growth and finishing | Consistent texture and durability |

| Plant composites | Material consistency and coatings | Higher bio-content with stable wear |

| Cultured proteins | Bioprocess complexity | Reliable batches and lower energy intensity |

Scale is not only a technical goal. It is what determines real-world availability and price.

The Finishing Step: Where Sustainability Often Gets Complicated

A major turning point for many alternatives is finishing. Raw mycelium sheets may need treatments to become water-resistant and abrasion-resistant. Plant composites often need coatings. These steps can improve performance but reduce biodegradability.

This is not automatically bad. A luxury item must survive daily use. The issue is transparency and end-of-life realism.

When evaluating claims, look for clarity on:

- What coatings are used and why

- Whether the coating is thin and minimal or thick and plastic-like

- Whether the final product can be repaired or refinished

- Whether take-back programs exist for hard-to-recycle composites

If a brand refuses to discuss finishing, assume the sustainability story is incomplete.

Lab-Grown Materials And The Question Of Microplastics

A hidden downside of many leather alternatives is microplastic shedding. Plastic-based “vegan leather” can crack and shed fragments over time, especially in heat and friction.

Biofabricated materials may reduce this risk, but only if finishing choices avoid heavy plastic layers. Plant-based composites vary widely. Some are close to plastic composites. Others use thinner coatings.

Microplastic Risk Quick Guide

- Highest risk: thick PU-based surfaces that crack and peel

- Medium risk: plant composites with thick synthetic coatings

- Lower potential risk: biofabricated surfaces with minimal synthetic layers

- Unknown: new materials without long-term wear data

This is one of the reasons durability testing matters. Sustainability is not only about how something is made, but how it behaves after years of use.

How To Talk About Lab-Grown Materials Without Overclaiming

For journalism and brand communication, the safest approach is precision. Avoid sweeping claims like “zero impact” or “always greener.” These claims rarely hold across producers and regions.

A better approach is to make claims in layers:

- Animal welfare claim: animal-free sourcing, cruelty reduction

- Traceability claim: documented supply chain and production controls

- Environmental claim: supported by footprint reporting and clean energy use

- Product claim: durability, repair options, and warranty support

When these layers align, the story is strong. When they do not, consumers notice.

How Lab-Grown Materials Fit Into The Green Tech Revolution

This cluster connects to digital life in a subtle but important way. The Green Tech Revolution is not only about energy and hardware. It is also about supply chains, traceability, and systems that reduce cruelty and extraction.

Lab-grown materials reflect a broader innovation pattern:

- Shifting from extraction to controlled manufacturing

- Using data and process control to improve consistency

- Creating new materials with engineered performance

- Building transparency into the production story

In the same way green web design reduces waste in digital infrastructure, lab-grown materials reduce waste and harm in physical products that support our lifestyles.

Final Thoughts

Lab-grown materials are redefining luxury by separating prestige from extraction and cruelty. Lab-grown diamonds show how controlled processes can create real gemstones without mining. Biofabricated leather and engineered alternatives show how material science can reduce dependence on animals and reshape product design.

Still, the label is not enough. Sustainability depends on energy sources, durability, and transparency. The best products will be those that last, can be repaired, and are produced with clean energy and clear reporting.

If you judge this space by measurable outcomes rather than marketing, you will see the real story. Lab-grown materials are not a perfect solution, but they are one of the most meaningful signals that luxury is moving toward a future built on innovation, traceability, and smarter systems.