Are you chasing missing boxes and late shipments, feeling buried by miscounts and stockouts? You know a small mistake can ripple through your whole operation. You want smooth inventory management but you hit delays and angry customers.

Key Takeaways

- Many warehouses run at 75% inventory accuracy. Use barcodes, SAP EWM, or Scandit to scan in real time and aim for 100%. This cuts waste and stockouts.

- Track inventory turnover by dividing cost of goods sold by average stock. Real-time label readers boost turnover, slash storage costs, and keep stock fresh.

- Ship 98% of orders on time and fulfill 95% correctly the first time. Log dates in a WMS to spot late loads and trim return costs.

- Watch a 5% return rate (50 returns per 1,000 items sold). Log returns in your WMS or Excel, fix defects fast, and plan smart restocks.

- Scan rack space daily to hit full capacity and divide total labor cost by orders. This finds slow steps, cuts time, and lifts worker morale.

Inventory Accuracy

Inventory accuracy measures the match between digital records and physical stock. You calculate it as the units tracked by your inventory management system divided by the items on the shelf.

Scores close to one mean fewer inaccuracies. Strong accuracy cuts waste and supports supply chain flow.

Warehouse management systems and barcoding systems speed checks and spot mistakes. Computerized inventory tracking also logs adjustments in real time. Ecommerce platforms rely on this metric for customer satisfaction and loss prevention.

Better accuracy can boost inventory turnover and cut costs.

Inventory Turnover

Managers track how often stock leaves shelves. They divide sales made by average stock to get turnover. The formula also uses cost of goods sold over average stock. That rate reflects product demand and buying practices.

Some teams plug data into Inventory Management Software or Enterprise Resource Planning. Those tools read inputs from label readers, update counts in real time.

High turnover cuts storage costs and drives fresh stock. Teams track inventory turnover in real time. That shift feeds into demand forecasting and supply chain plans. It boosts customer satisfaction and trims waste.

Sharp managers use inventory management data to tune reorder points at each SKU. They monitor trends, tweak purchases, refine workflows, all with Inventory Management Systems.

Receiving Efficiency

Receiving efficiency measures how fast staff process incoming goods. Teams use the formula volume of inventory received divided by staff hours. A unit that logs 500 items in 25 hours scores 20 items per hour.

This metric drives solid inventory management and maps turnover trends. Staff log data by source and time with a Warehouse Management System and RFID scanners. Lean methods and just-in-time checks trim slack at the dock.

Warehouses link ERP tools and spreadsheet logs to spot slow check-ins. Supervisors scan barcodes, time each pallet from 9 AM to 5 PM, and track 320 daily loads. That record lets teams set goals that boost customer satisfaction.

Workers swap tips in brief huddles to speed each scan. Fewer hours per unit means faster shipping and happier buyers.

Putaway Accuracy Rate

Putaway accuracy rate tracks how well staff place items in correct slots. You calculate it as Inventory Put Away Correctly divided by total putaway units. A score of 1 shows perfect accuracy with zero errors.

Warehouse managers use this KPI with a Warehouse Management System and RFID scanner to refine slotting and cut picking mistakes. Staff scan barcode labels to speed correct placement.

High accuracy pairs with steady inventory turnover to boost inventory management and cut storage waste.

Order Picking Accuracy

Managers calculate order picking accuracy with a clear formula. They compute (Total Number of Orders Incorrect Item Returns) divided by Total Number of Orders. They aim for a value close to 1 to minimize mistakes in inventory management.

This metric highlights error trends fast.

Workers scan each item using a label reader or they mount picks on a pick to light board. Systems like a warehouse management system log every scan, they trigger alerts on mismatches.

Teams run batch picking drills and track audit results on dashboards. Quick fixes here trim return costs and boost customer smiles.

On-Time Shipping Rate

Staff check each order by its promised ship date. They log times in warehouse software. The system flags any late loads against the service level agreement.

They use this formula, Orders Shipped On Time or In Advance over Total Orders Shipped. That percent shows if carriers meet targets. A 98 percent rate keeps clients happy.

Order Fulfillment Rate

Order Fulfillment Rate tracks how many orders ship without a hitch. It divides Orders Completed Without Issues by Total Orders Received. A 95% rate means 950 out of 1,000 orders go out right the first time.

Warehouse Management System dashboards and scanners feed this metric in real time.

A crisp rate cuts waste and boosts morale. A picker once quipped that losing a single box felt like misplacing a pirate’s treasure. You spot hiccups fast, tweak packing steps, or swap a carrier.

Teams watch this number on daily reports.

Warehouse Capacity Utilization

Warehouse capacity utilization tracks how much storage space you use. It shows how much of your racking systems and floor area work at once. Empty aisles lower revenue, and underused bins waste room.

Good slotting boosts density in tight spots. Strong layout design helps flow from dock to dock. Teams use inventory software and tag scanners to map space in real time.

Managers run daily scans with code scanners to spot open bays. They watch fill rates in dashboards. Lift truck operators note empty racks and report gaps. They shift slow sellers to less busy aisles.

You can add belt system lines to free up key zones. Automation tools push real-time alerts when space falls below target. This mix cuts wait times and clears lanes faster.

Labor Productivity and Efficiency

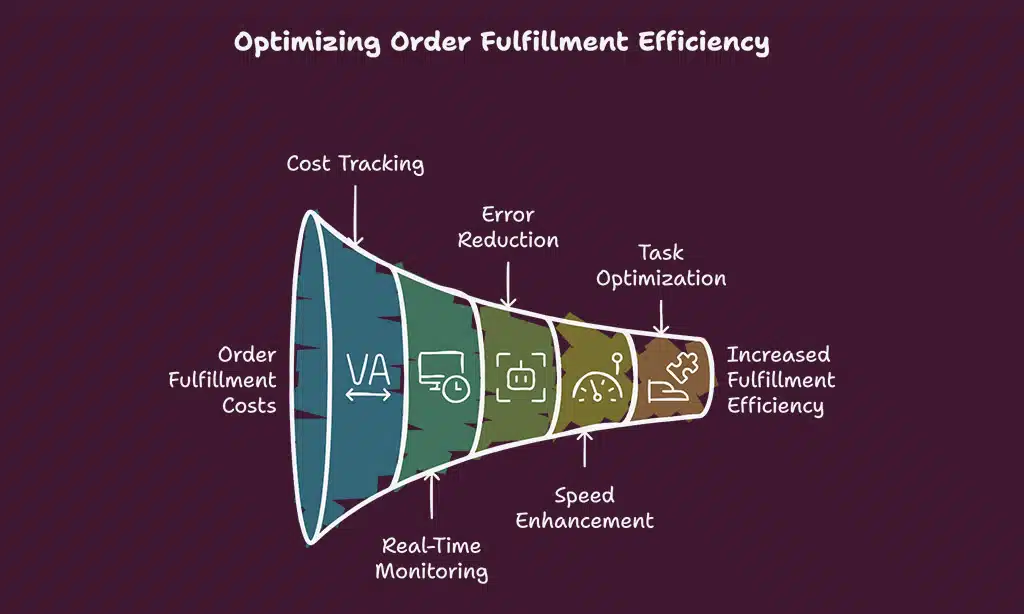

Managers track cost per order to gauge labor output. They use a simple formula, divide total fulfillment costs by total number of orders. That metric highlights each worker’s impact.

Teams log picking and packing costs, like cost per line and labor cost. A stockroom tracker shows real-time pace. It measures orders picked per hour. Leaders watch that rate like a hawk.

Operators use scanning wands and tag readers to cut errors. A crew may pick 60 orders per hour. That speed trims time and cost. Workforce management software logs staff hours and output.

It shines a light on slow steps. This clarity helps managers swap tasks, boost speed.

Rate of Returns

Rate of returns shows how many items customers send back, and it flags trouble fast. It comes from (Items Returned / Items Sold) * 100. If a warehouse sells 1,000 items and sees 50 returns, the rate hits 5%.

You feed return data into a Warehouse Management System or Excel sheet. Teams review returned inventory feedback to spot product defects and shipping damage, nipping problems in the bud.

Reverse logistics then guides smart restock plans and cuts waste.

Safety Performance

Leaders monitor accidents per year with clear eyes. They set the goal at zero, it feels bold, but it works. Teams record incidents in EHS software, it acts as a digital safety net.

They count time since last accident in days. That count climbs with each hazard spot and fix. A long streak of safe days earns cheers, and even a high five. Forklift drivers wear sensors that buzz at risky moves.

Safety audits come around like clockwork. Staff use tablets for training modules, they even enjoy the quiz. The Safety Program covers all corners, from rack checks to spill kits. Managers sip coffee, compare audit logs, and spot trends.

Ergonomics drills keep backs and knees happy. Workers chat over lunch about a near miss. That tale sparks action, and leaders spring into fixes.

Takeaways

Every KPI helps managers spot weak spots and boost performance. Data from tracking systems and management software guide daily choices. A smart dashboard shows Inventory Turnover, Order Picking Accuracy, and On-Time Shipping Rate in real time.

Teams stay sharp when they view live metrics on a tablet or PC. Warehouses win when they measure well, act fast, and refine each step.

FAQs

1. What key metrics keep a high-performing warehouse running like a well-oiled machine?

The ten essential key numbers track accuracy, turnover, pick speed, on-time rate, and fill rate. They help you catch mistakes, free up space, and keep cash flowing.

2. How do we watch accuracy without losing our cool?

Think of accuracy as order correctness. We run spot checks, scan each item, note slip-ups, then fix them pronto. It’s like brushing your teeth each night—small effort, big payoff.

3. Why is turnover the name of the game in a busy warehouse?

Turnover shows how fast stock moves. Slow items pile up, and that’s like wearing socks with sandals, nobody wants that. High turnover clears shelves, cuts waste, and boosts cash.

4. How do we nail on-time shipments and dodge last-minute chaos?

On-time rate measures orders sent by the promised date. We map each step, spot the slow spots, tweak the plan, train teams, and set alerts. It keeps us on our toes, ready to roll.