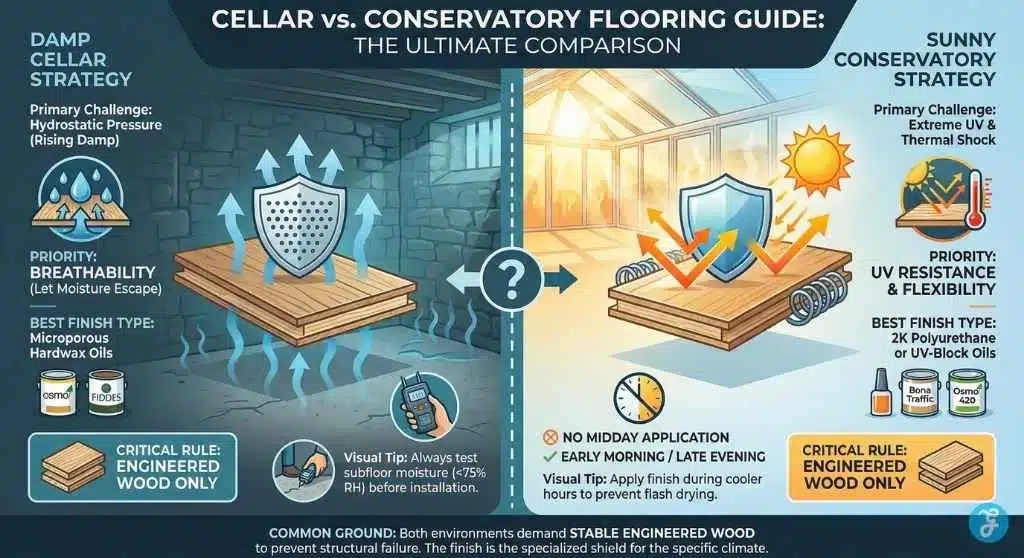

Converting a damp cellar or adding a sun-drenched conservatory are two of the most popular home improvements in the UK. However, they are also the most hostile environments for natural timber. If you are searching for the best wood floor finish to protect your investment, you have likely already realised that a standard tin of varnish from the high street simply won’t suffice. These unique spaces attack wood from two opposing directions: moisture rising from the ground below, and intense heat and UV radiation beating down from above.

Finding the best wood floor finish is not just about aesthetics; it is about engineering a survival strategy for your flooring. In a cellar, the enemy is hydrostatic pressure—invisible moisture vapour trying to push through the floor. In a conservatory, the “greenhouse effect” can bake timber, causing it to shrink, while UV rays bleach rich oak tones into a lifeless grey.

This guide explores 11 specific finishes that have been formulated to withstand these extremes. Whether you are a trade professional or a DIY enthusiast, this list prioritises products that offer the perfect balance of breathability, flexibility, and durability.

Key Takeaways

-

Substrate Rule: Never use solid wood in these environments. Engineered wood is the only viable option.

-

Cellar Strategy: Priority is breathability. Use microporous Hardwax Oils that allow moisture vapour to escape without blistering the finish.

-

Conservatory Strategy: Priority is UV resistance and flexibility. Use finishes with UV blockers to prevent bleaching and flexible resins to handle heat expansion.

-

Top Picks: Osmo Polyx-Oil remains the gold standard for damp areas, while Bona Traffic HD is the unshakeable choice for high-traffic, sun-drenched spaces.

The Science: Why Standard Finishes Fail

Before selecting a tin, it is crucial to understand why standard lacquers fail in these specific rooms.

The Cellar Challenge: Hydrostatic Pressure

Even with a modern damp-proof membrane (DPM), cellars have higher relative humidity than the rest of the house. Concrete subfloors act like sponges. If you use a cheap polyurethane varnish, it forms a plastic-like seal on top of the wood. When moisture vapour rises from the subfloor, it gets trapped under this plastic skin. The result? The finish turns cloudy (milky), blisters, and eventually peels off in sheets.

-

The Solution: You need a microporous finish. Think of this like Gore-Tex for your floor. It prevents water spills from penetrating downwards but allows moisture vapour to escape upwards.

The Conservatory Challenge: UV Bleaching and Thermal Shock

A south-facing conservatory in the UK can experience temperature swings of 30°C in a single day. Wood is hygroscopic—it expands when warm/humid and shrinks when cold/dry. A brittle, standard varnish will snap and crack under this movement. Furthermore, glass intensifies UV radiation, which breaks down lignin in the wood, causing rapid discoloration.

-

The Solution: You need a finish with high resin elasticity and added UV blockers.

Strategic Selection: Matching the Finish to the Environment

Before diving into the specific brand recommendations, it is vital to categorise your room’s primary threat level. Not all “difficult” environments require the same defence mechanism. While a conservatory demands a shield against the sun, a cellar requires a valve for moisture.

To choose the best wood floor finish for your specific project, you must prioritise one of two distinct properties:

-

Permeability (The Cellar Priority): If your room is below ground level, a converted garage, or an older property with solid walls, your absolute priority is breathability. You need an “Open Pore” finish. This allows the timber to regulate its moisture content naturally, letting vapour pass through without pushing the finish off the surface.

-

Elasticity & UV Blocking (The Conservatory Priority): If your room is largely glass, your priority is flexibility. You need a “Film-Forming” finish (lacquer) or a high-solid oil that can stretch and shrink with the wood as temperatures spike, combined with chemical UV filters to prevent rapid fading.

With these distinct strategies in mind, we begin with the products designed to tackle the most common and risky UK renovation challenge: the damp environment.

Category 1: The “Breathable” Champions (Best for Damp Cellars)

When dealing with basements, the best wood floor finish is almost always an oil or hardwax oil. These penetrate the timber rather than sitting on top, allowing the wood to breathe.

1. Osmo Polyx-Oil Original

The UK Market Leader

Osmo has achieved cult status in the UK for a reason. It is the definitive hardwax oil, combining natural vegetable oils (sunflower, soybean, thistle) with carnauba and candelilla waxes.

-

Why it works in cellars: The oils penetrate deep into the wood pores to protect from within, while the waxes form an elastic, microporous surface. It does not crack, flake, or peel even when the humidity in a cellar fluctuates.

-

Application: It is incredibly forgiving. Two thin coats are all that is required. If a specific area gets damaged by damp, you can spot-repair it without sanding the whole floor—a massive advantage in a basement utility room.

2. Fiddes Hard Wax Oil

The Trade Professional’s Choice

Ask a UK flooring contractor for their go-to finish, and they will likely say Fiddes. It is formulated to dry faster than Osmo, which is critical in cellars where air circulation can be poor and drying times are often extended.

-

Performance: It offers excellent water resistance. In independent tests, Fiddes often edges out competitors for resistance to liquid spills (coffee, wine), making it ideal if your cellar conversion includes a bar or kitchenette.

3. Treatex Hardwax Oil Ultra

The Sustainable Option

Treatex offers a slightly warmer, more golden hue than Osmo. It is manufactured on a base of sustainable raw materials including Jojoba and Linseed oil.

-

The “User-Friendly” Factor: This is arguably the easiest product to apply for a DIYer. It has a slightly thinner viscosity, meaning it spreads further and is less likely to leave brush marks. For a cellar that might be cooler than the rest of the house, this flow is essential for a smooth finish.

4. Rubio Monocoat Oil Plus 2C

The High-Tech Speed Solution

Rubio is unique. It uses “molecular bonding” technology, meaning the oil adheres to the cellulose fibres of the wood instantly. The “2C” stands for two-component: you mix the oil with an accelerator.

-

Why it’s a game-changer: It cures fully in roughly 5-7 days, but is walkable in 24 hours. In a damp environment, reducing the “open” time where the floor is wet is a huge benefit. It is also a single-coat application—saving you a day of labour.

Comparison of Breathable Cellar Finishes

| Product | Base Type | Curing Time | Sheen Levels | Best For |

| Osmo Polyx-Oil | Oil/Wax Blend | 8-10 Hours | Matt, Satin, Gloss | General Living Areas |

| Fiddes Hard Wax | Oil/Wax Blend | 4-6 Hours | Matt, Satin, Semi-Gloss | Kitchenettes/Bars |

| Treatex Ultra | Jojoba/Linseed | 3-6 Hours | Matt, Satin | DIY Application |

| Rubio Monocoat | Molecular Oil | 24 Hours (Full cure 5 days) | 40+ Colours | Speed & Colour |

Category 2: The “Armour Plating” (Best for Conservatories)

In a conservatory, you are fighting the sun. The best wood floor finish here must essentially be a sunscreen for your floor.

5. Bona Traffic HD

The Durability King

If your conservatory is the main route to the garden, it will see mud, grit, and wet shoes. Bona Traffic HD (High Durability) is a two-component water-based lacquer. It is widely regarded as the toughest finish on the market.

-

Why it works: Despite being a lacquer, it has incredible flexibility. It can move with the wood as the conservatory heats up and cools down. It also has very low VOCs, so it won’t gas off unpleasant smells when the room gets hot.

6. Osmo UV-Protection-Oil Extra (420)

The Sun-Blocker

Standard oils offer zero UV protection. This specific formulation from Osmo includes UV inhibitors (similar to Factor 12 sunscreen) which slows the greying process by a factor of 12 compared to untreated wood.

-

Specific Use Case: This is strictly for vertical surfaces or low-traffic floors, BUT many homeowners use it as a base coat in conservatories, topped with Polyx-Oil for durability. It also contains biocides, preventing algae growth if your conservatory suffers from condensation.

7. Junckers Strong Premium

The Non-Yellowing Scandi Look

Oil-based varnishes have a tendency to turn orange (ambering) when exposed to intense sunlight. Junckers, a Danish brand, produces this water-based lacquer that stays crystal clear.

-

Why it works: It preserves the natural, pale look of oak or ash. If you have a modern, airy conservatory and want to avoid that “antique pine” orange look, this is the best wood floor finish for clarity.

8. Loba 2K Invisible Protect

The “Raw Wood” Trend

Current trends favour wood that looks unfinished. Loba 2K Invisible Protect is a water-based coating that looks and feels like raw wood but offers the protection of a high-traffic varnish.

-

Glare Reduction: In a conservatory, a glossy floor can be blinding. Loba absorbs light rather than reflecting it, making the room much more comfortable to sit in during midday sun.

Category 3: Specialist & Trade Solutions

Sometimes the best wood floor finish is a specialised product designed for specific, tricky scenarios.

9. Morrells Induro XL1

This is an anti-microbial, high-performance lacquer often used in commercial settings.

-

Best For: Cellars converted into gyms or utility rooms. It has high chemical resistance, meaning detergent drips or sweat won’t degrade the finish over time.

10. Blanchon Hard Waxoil

A favourite in France and the UK, Blanchon uses a unique blend of vegetable oils and natural waxes.

-

Best For: Dusty cellars. It has a high resistance to static, meaning it attracts less dust than polyurethane varnishes, keeping the air quality in your basement cleaner.

11. Liberon Natural Finish Floor Varnish

While Liberon is often seen as a DIY brand, its “Natural Finish” line is surprisingly robust.

-

Best For: Budget-conscious renovations. It is readily available at UK hardware stores like Screwfix. It uses “soft resin” technology to prevent cracking, making it a viable budget option for conservatories.

Cost vs. Coverage: Planning Your Budget

When selecting the best wood floor finish, the price per tin can be misleading. A cheap varnish often has poor coverage, meaning you need more tins to finish the job. Conversely, high-quality oils like Osmo or Rubio Monocoat may seem expensive upfront, but spread much further, often working out cheaper per square metre.

Below is a breakdown of the estimated coverage and relative costs for the top contenders.

Cost Efficiency Breakdown

| Brand | Finish Type | Approx. Coverage | Coats Needed | Value Verdict |

| Osmo Polyx-Oil | Hardwax Oil | 24m² per litre | 2 | Best Value (High coverage compensates for price) |

| Bona Traffic HD | 2K Lacquer | 8-10m² per litre | 2-3 | Premium (Expensive but unmatched durability) |

| Fiddes Hard Wax | Hardwax Oil | 20-24m² per litre | 2 | High Value (Excellent coverage for the price) |

| Rubio Monocoat | 2C Oil | 30-50m² per litre | 1 | Time Saver (Highest coverage, only 1 coat needed) |

| Liberon Varnish | DIY Varnish | 10-12m² per litre | 3 | Budget (Low upfront cost, but requires more product) |

Note: Coverage rates vary based on wood porosity. Engineered Oak tends to be less thirsty than softwoods like Pine.

Application Guide: Success in Difficult Rooms

Even the best wood floor finish will fail if applied incorrectly. The rules change when you are underground or under glass.

For Damp Cellars: The “Acclimatisation” Rule

The biggest mistake DIYers make in cellars is rushing.

-

Moisture Check: Before bringing wood in, the concrete subfloor must be less than 75% Relative Humidity (RH). If it is over 75%, you must use a liquid damp-proof membrane (DPM) first.

-

Acclimatise: Bring your engineered wood into the cellar and let it sit for at least 7 days (longer than the standard 48 hours). It needs to adjust to the unique humidity of the basement before you seal it.

-

Thin Coats: When applying oil (like Osmo), apply it thinly. In a damp cellar, thick oil will not cure; it will remain sticky for weeks.

For Conservatories: The “Temperature” Rule

Applying finish in a conservatory is a race against the sun.

-

Timing: Never apply the finish when the sun is beating down. The floor can reach 40°C+, causing the finish to “flash dry” before it levels out, leaving brush marks and bubbles.

-

The Dawn Raid: The best time to varnish a conservatory is 6:00 AM or late evening.

-

Tape Windows: If you are using a UV-cured oil, consider taping newspaper over the lower windows during the application to prevent premature curing.

Application Troubleshooting

| Problem | Cause (Cellar/Conservatory) | Solution |

| White Spots/Blooming | Trapped moisture in the cellar floor. | Sand back, ensure subfloor is dry, use Microporous Oil. |

| Sticky Surface | High humidity prevented curing. | Increase ventilation/heat. Do not add more coats. |

| Bubbles in Varnish | Applied when the conservatory was too hot. | Screen (light sand) the floor and recoat at 6 AM. |

| Peeling | Wrong finish used (Non-flexible). | Full sand required. Switch to Bona Traffic or Osmo. |

The Essential Tool Kit: Don’t Ruin the Finish

Using the wrong applicator is the fastest way to ruin even the best wood floor finish. The chemicals in these products react differently to synthetic and natural fibres.

For Hardwax Oils (Osmo, Fiddes, Treatex):

-

Natural Bristle Brush: Essential for cutting in the edges. Synthetic bristles often “flick” the oil, creating a mess.

-

Microfibre Roller (Short Pile): Use a 5mm nap roller. A long pile (fluffy) roller will apply too much oil, leaving sticky rings on the floor that will not cure in a damp cellar.

-

Lint-Free Cloths: Vital for wiping away excess oil if you apply too much.

For Lacquers (Bona, Junckers, Loba):

-

Synthetic Brush: Water-based lacquers swell natural bristles, making them useless. Use a high-quality synthetic brush for edges.

-

Medium Pile Roller: An 8-10mm roller helps lay down a thick, wet layer of lacquer, which is necessary for it to self-level and dry smooth.

-

Mixing Bucket: For 2-component finishes (like Bona Traffic), you must mix the hardener and lacquer in a separate bucket, not in the tin.

Maintenance: Extending the Lifespan

Once you have applied the best wood floor finish, maintenance is the key to longevity.

In the Conservatory: You must use a “Refresher” product. UV rays slowly eat away the top layer of oil.

-

For Oil: Use Osmo Liquid Wax Cleaner every 6 months. It feeds the wood and replenishes the waxes.

-

For Lacquer: Use Bona Freshen Up. It adds a sacrificial layer of polyurethane to take the scratches from garden grit.

In the Cellar: Ventilation is your friend.

-

Keep air bricks clear.

-

Avoid wet mopping. Use a spray mop (like the Bona Spray Mop) to avoid introducing excess water into an already damp environment.

-

If you see a grey patch developing (usually near a door), spot-repair it immediately with hardwax oil before the damp gets into the timber grain.

Frequently Asked Questions on Cellar & Conservatory Flooring

1. Can I use solid oak flooring if I buy the best wood floor finish available?

No. This is a fundamental structural issue, not a finish issue. Solid oak is unstable. In a damp cellar, it will “cup” (edges curl up). In a hot conservatory, it will shrink and leave massive gaps. You must use Engineered Wood, which has a plywood base to stabilise the top layer. The finish protects the surface, but it cannot stop solid wood from warping physically.

2. How do I know if my cellar is too damp for wood flooring?

You need to test the concrete slab. You can buy a simple hygrometer or hire a professional to do a “calcium carbide” test. If the Relative Humidity of the screed is above 75%, you need to apply a liquid epoxy DPM (Damp Proof Membrane) before laying any flooring, regardless of the finish you choose.

3. Which is better for a conservatory: Oil or Lacquer?

There is no single “better” option, but there is a trade-off.

-

Oil (e.g., Osmo): Easier to repair if sun damage occurs, but requires more maintenance (re-oiling every 12-18 months).

-

Lacquer (e.g., Bona): tougher against scratches and requires zero maintenance for years, but if it eventually cracks or peels from sun damage, you have to sand the entire floor back to bare wood.

4. Will a UV oil stop my floor from changing colour completely?

Honesty is key here: No. A UV oil like Osmo 420 drastically slows down the colour change, but nothing stops the sun forever. Wood is a natural product and will mellow over time. However, using a UV finish prevents the ugly “bleached bone” look and keeps the wood looking natural and rich for years longer than standard oil.

5. Why does my cellar floor finish look milky?

This is a classic sign of trapped moisture, often called “blooming.” It means you likely used a non-breathable lacquer over a damp subfloor. The moisture is trying to escape and is trapped under the varnish. To fix this, you unfortunately need to sand it back and switch to a breathable Hardwax Oil (Category 1).

Final Thought: Best Wood Floor Finish

Choosing the best wood floor finish for a UK cellar or conservatory is about respecting the environment. You are asking wood to survive in conditions it does not naturally like.

If you are dealing with the damp, cool conditions of a cellar, Osmo Polyx-Oil or Fiddes Hard Wax Oil are your safest bets. They allow the floor to breathe and move without failing. If you are tackling a high-traffic, sun-baked conservatory, the industrial toughness and flexibility of Bona Traffic HD or the UV protection of Osmo 420 are essential.

By pairing the right engineered timber with the correct specialist finish, you can create a stunning, durable space that withstands the unique rigours of the British climate.