Ventilation problems often come down to a simple misunderstanding of which fan is actually needed. An axial fan is a great choice for straightforward systems where there’s no significant resistance in the ducts and high pressure isn’t required. But when the system includes bends, filters, or long channels, an axial fan just can’t keep up. It starts making noise, works under overload, and the air flows where it wants, not where it should.

As a result, air stagnates, and the ventilation stops doing its job. It’s time to think about a different type of equipment.

Why a radial fan performs where others fail

A radial fan can generate much higher static pressure, which is crucial in complex systems with multiple obstacles. Thanks to its impeller design with forward-curved blades, the air is effectively “drawn in”, gains speed, and is “pushed out” with the necessary force.

Blauberg has long specialized in these solutions. Their range is characterized by a well-thought-out choice of materials, motor types, and installation options. All units are equipped with a robust steel housing and motors designed for long-term operation without overheating. This approach is a guarantee of stable operation even in difficult conditions.

Key characteristics: impeller, motor type, installation

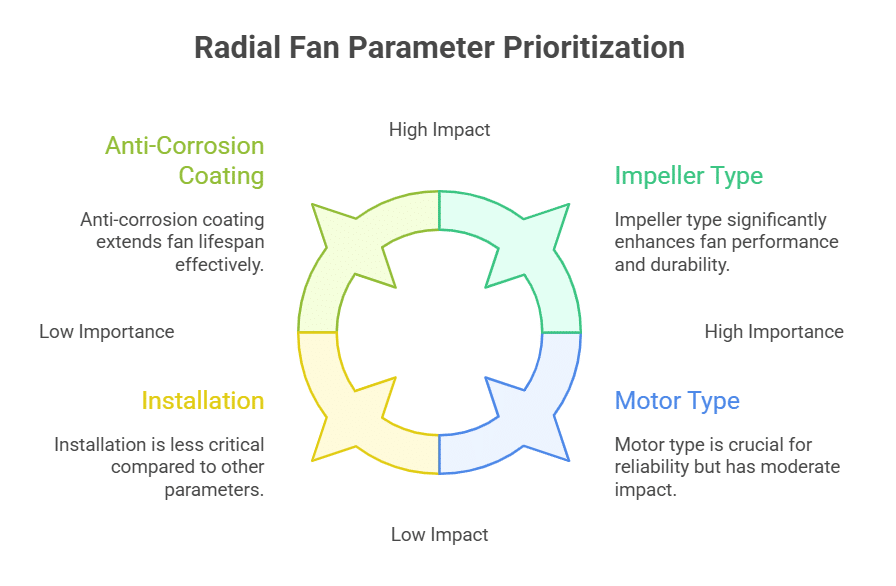

To understand why a radial fan wins in the battle against low pressure, it’s worth focusing on three main parameters.

First, the impeller type. Radial fans typically have forward-curved blades that efficiently create high pressure and resist contamination. An anti-corrosion coating is very important – this extends the fan’s lifespan.

Second, the engine. AC motors are the most common choice for industrial applications – reliable and economical. Blauberg models often feature enhanced cooling systems that reduce the risk of overheating during prolonged operation.

Third, installation. Radial fans are usually installed where the airflow must overcome resistance – bends, filters, narrow sections. Proper installation helps maximize the equipment’s potential.

What Blauberg offers: a brief overview

Blauberg’s lineup includes models with different designs and power levels. Here are a couple of notable options:

- Helix fans – time-tested construction with AC motors, radial impellers with forward-curved blades, and coated steel casings. Ideal for industrial and commercial facilities;

- S-Vent fans – more compact models with similar features, suited for tighter spaces.

Each solution is adapted for specific tasks – from simple ventilation systems to complex industrial setups. The company’s website provides detailed technical specifications to help select the right option for the particular project conditions.

Concluding remarks

Insufficient pressure in ventilation isn’t a reason to settle for discomfort. Sometimes switching the fan type is exactly what a system needs to finally work quietly and efficiently. In this case, a radial fan is a proven and effective solution. When the choice is made consciously, considering characteristics and real conditions, many mistakes can be avoided.