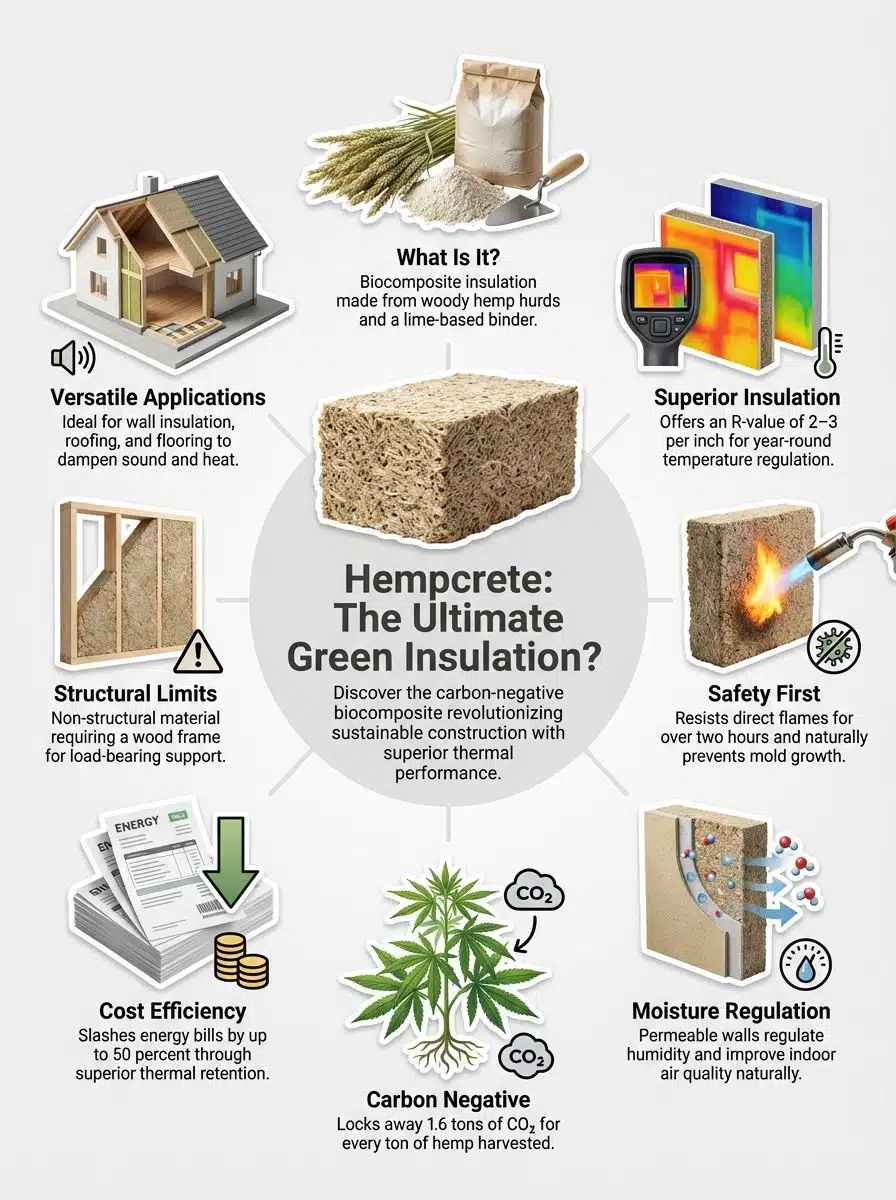

Finding the best way to keep your house warm in winter and cool in summer is a real struggle. Bills climb, old insulation gets soggy, and then there’s mold. Nobody wants that headache. Here’s something interesting: hempcrete, a mix of hemp fibers and lime, actually traps more carbon than it creates. This makes it stand out from most building materials.

In this post, I will break down exactly what hempcrete is and explain why many call it a game-changer for green construction. We’ll cover what goes into it, its superpowers like thermal performance, what holds it back, and where you can use it around the house.

Stick with me. This might be the answer you’ve been looking for.

What is Hempcrete?

Hempcrete is a biocomposite insulation made from hemp hurds and a lime-based binder. Builders mix the woody core of hemp plants with water and lime, then use this mix to make walls, floors, or roofs in green construction projects.

It creates eco-friendly buildings that breathe well and help cut down the carbon footprint. The use of hempcrete goes way back, but it grew popular in France during the 1990s as people searched for sustainable building materials. It’s like nature’s own sponge because it is lightweight, strong against fire, and kind to Earth.

Unlike concrete, hempcrete does not support heavy loads by itself. It works well with wood frames because it is so lightweight and easy to handle on-site.

Recent changes in the United States have made this material even more accessible. The 2024 International Residential Code (IRC) added “Appendix BL,” which officially approves hemp-lime for use in residential construction. This is a massive step forward for builders who previously faced hurdles with local building departments.

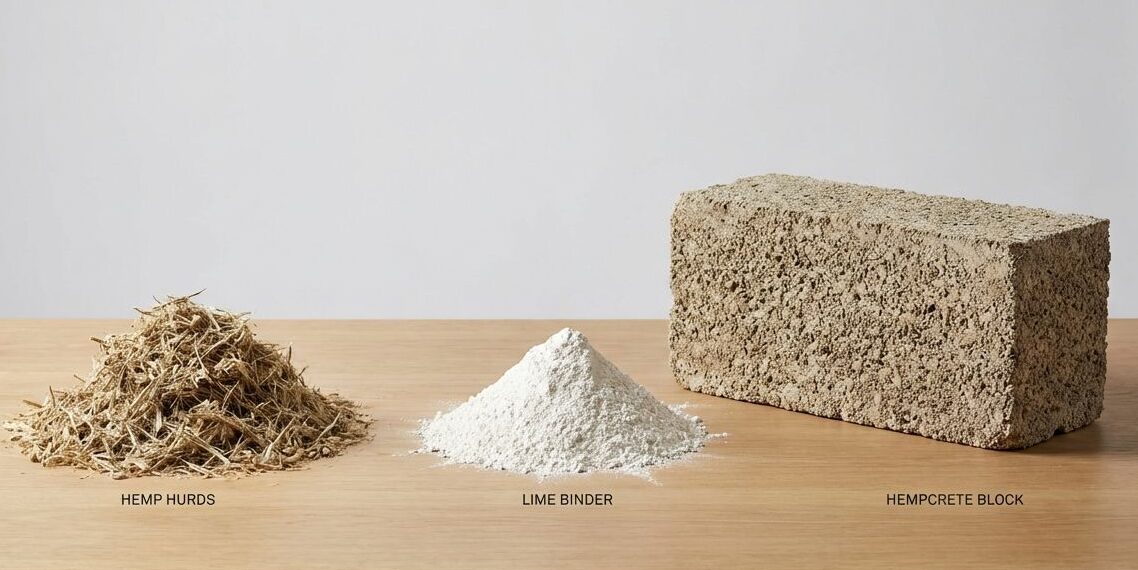

Composition of Hempcrete

Hempcrete mixes pieces of hemp stalk with a lime binder. Some makers tweak the mix to boost its performance, giving it a bit more oomph for different climates.

Hemp hurds and lime-based binder

Hemp hurds come from the woody core of hemp stalks. Farmers break the plant and separate these small, chunky pieces during harvest. These hurds work well for insulation because they trap air, making them light and strong at the same time.

Builders mix these bits with a lime-based binder to form a paste. This natural binder holds everything together like glue in a puzzle. A standard mix often follows a 4:1 ratio of hemp to binder, though this varies by application. The lime gives strength, stops mold growth, and lets walls breathe. Lime also keeps pests away and helps cut down on fire risks.

By using this blend of hemp hurds and lime binder, people create an eco-friendly material that stays cool in summer and warm in winter. This biocomposite is renewable and cuts down carbon footprint through both its raw materials and how it soaks up CO2 as it hardens over time.

It’s easy on the planet while giving sturdy support for green building projects across many settings.

Additives for enhanced performance

Hemp hurds mixed with a lime-based binder lay the groundwork, but builders often add extra ingredients to tweak hempcrete’s performance. Small amounts of clay, pozzolans, or mineral powders can make the material stronger or help it set faster.

Some mixes use natural fibers like flax or jute for more durability and flexibility. Water repellents may be added to boost resistance against moisture without hurting breathability.

Chemical-free additives keep everything eco-friendly and safe for people living in green buildings. Different climates call for different tweaks. For example, adding silica makes hempcrete less likely to crack in dry areas. Builders test new blends every year to cut costs and improve insulation properties.

“Sometimes you need just a pinch of magic dust (well, science calls them additives) to make great materials even better.”

Key Properties of Hempcrete

Hempcrete keeps your home cozy in winter and cool in summer. It helps walls breathe easy, standing guard against both fire and mold.

Thermal insulation and high R-value

Walls made with hemp and lime hold in warmth like a thick blanket. They stop heat from leaking out in winter, and they keep rooms cool in summer. With an R-value of about R-2.0 to R-2.5 per inch, these biocomposite panels perform consistently well.

Builders can stack the blocks or spray them between wooden frames for even more thermal performance. The real secret here is “thermal mass.” Unlike lightweight fiberglass, hempcrete walls are dense enough to store heat during the day and release it slowly at night. This “phase shift” means your home stays comfortable for hours even after the heating turns off.

Many homeowners save money on their heating and cooling bills thanks to this natural insulation. You will find less need for extra foam or fiberglass, which lowers your carbon footprint, too. The air stays fresh, energy use drops, and the space feels cozy year-round.

Fire resistance and mold resistance

Hempcrete stands up well to fire. This biocomposite resists burning, so it helps protect homes if a flame sparks up nearby.

It generally achieves an ASTM E84 Class A fire rating, which is the highest standard for building materials. Firefighters in France tested hempcrete back in 2012. They found that a wall made of this insulation stayed strong for over two hours against direct flames. That is more than most common building materials can handle.

Mold struggles to grow on hemp and lime mixtures. The high pH level of the lime binder creates an environment where mold simply cannot survive. The breathability of hemp walls keeps water from getting trapped inside the structure, cutting down mold risk and keeping indoor air fresh.

Homeowners love this feature in damp or humid places because healthier air means fewer allergy problems and less musty odor floating around. Next up comes breathability for moisture regulation, another key reason many builders pick hemp insulation today.

Breathability for moisture regulation

Air and water vapor move freely in hempcrete walls. This helps stop trapped moisture, which can cause mold or rot. The material acts like a sponge, taking in extra moisture from humid air, then letting it go when the air dries out.

As a result, rooms stay dry and fresh without fancy systems. This property is technically called “vapor permeability.”

Many builders love this natural insulation for its breathability. People report fewer allergy problems in houses with these walls because mold cannot grow as easily. Humid regions benefit most since traditional materials often trap dampness inside, raising health risks and ruining indoor air quality.

Benefits of Using Hempcrete

Hempcrete slashes your carbon footprint while making homes cozy, so stick around to find out how it can help you save cash and the planet.

Carbon-negative and sustainable

Making hempcrete uses plants that soak up carbon dioxide as they grow. For every cubic meter of hempcrete, an estimated 110kg of CO2 gets locked away in the material. This lowers the carbon footprint of any building project using it. Grows quickly and needs little water or pesticides, hemp is a renewable resource.

Farmers can harvest hemp in just 3 to 4 months, much faster than trees used for wood products. Fields go from seed to stalks ready for construction before you finish your summer reading list.

These eco-friendly biocomposites break down naturally and do not pile up in landfills forever, as many plastics or foam insulations do. Builders get insulation properties while also caring for the planet and future generations with this green option.

Energy efficiency and cost savings

Hempcrete acts like a warm blanket for homes, keeping heat inside during winter and blocking it out in summer. This strong thermal insulation can mean using heaters and air conditioners less often.

In France, studies show hempcrete walls slash energy bills by up to 50 percent compared to regular materials. Families see smaller electric bills while staying cozy all year.

The savings start even before you pay your first utility bill. Because hempcrete is so efficient, you can often install a smaller, less expensive HVAC system than you would need for a standard house.

Builders say that over time, savings on heating and cooling help cover construction costs, making homes cheaper to live in month after month.

Challenges and Constraints of Hempcrete

Hempcrete can’t hold up a house by itself, and finding the right materials or builders could take some extra digging. Curious how it stacks up against your needs? Keep reading.

Non-structural limitations

Builders cannot use this biocomposite to support roofs or heavy floors. Walls made with it must rely on a strong frame for strength. It works like a thick, warm coat around the building, but does not hold up to weight.

While the 2024 IRC Appendix BL now provides a clear path for residential use, it strictly defines hempcrete as a non-structural infill. This means you still need a traditional timber or steel frame to do the heavy lifting.

Many architects love its breathability and insulation properties, though they need to blend it carefully into green construction plans. Understanding its place helps teams pick the best spot for these natural insulation blocks in new homes or renovations.

Availability and cost considerations

Hempcrete is not easy to find in every state. Some areas have strict rules about hemp farming and use. This limits where you can buy hemp hurds, one of the key ingredients for this biocomposite material.

Cost matters too. As of 2025, hempcrete insulation material typically costs between $1.40 and $3.10 per square foot, whereas fiberglass insulation is often cheaper at $0.30 to $1.50 per square foot. However, these numbers don’t tell the whole story since hempcrete replaces insulation, drywall, and exterior sheathing all at once.

The table below breaks down the comparison for clarity:

| Material | Est. Cost (Material Only) | Primary Benefit |

|---|---|---|

| Fiberglass | $0.30 – $1.50 / sq ft | Cheap and widely available |

| Spray Foam | $1.00 – $4.00 / sq ft | High air sealing |

| Hempcrete | $1.40 – $3.10 / sq ft | Non-toxic, carbon negative, regulates moisture |

Skilled workers with experience using natural insulation might charge more by the hour due to special handling needs. You can find qualified professionals through directories like the US Hemp Building Association (USHBA) to ensure the job is done right.

Another major factor is time. A cast-in-place hempcrete wall typically needs to dry for about one week per inch of thickness. This means a standard 12-inch wall could take nearly three months to fully cure before you can apply the final plaster.

Applications of Hempcrete

Hempcrete fits right in as insulation for many spots around your house, and you might be surprised where else it shows up.

Wall insulation and prefabricated blocks

Wall insulation made with hempcrete keeps rooms warmer in winter and cooler in summer. These biocomposite blocks fit snugly into walls, helping to stop heat from sneaking out or drifting in.

Prefabricated hempcrete blocks, sometimes called “HempBlocks,” are a popular solution to the drying time problem. Since they are cured in a factory before they arrive at your site, builders can stack them immediately like big building toys.

Using these eco-friendly materials shrinks a home’s carbon footprint over its life. Many green construction projects use prefabricated hemp blocks for fast, clean jobs. Builders often choose them since the material is lightweight and easy to handle on-site.

They also help homes breathe, fighting mold while trapping heat where it belongs. Many homeowners say their energy bills drop after adding this natural insulation to walls built with renewable resources like hemp fiber and lime.

Roofing and flooring insulation

Hempcrete works well as insulation for roofs and floors. It fills gaps easily and keeps cold air out in winter, cool air in during summer. Builders lay hempcrete between rafters or on subfloors to control temperature throughout the year.

Its lightweight nature does not add much strain to roof structures. For retrofits, you can use hemp fiber batts, which are flexible mats similar to fiberglass but without the itch or glass fibers.

This biocomposite also blocks sound from outside and inside rooms, making buildings quieter. Hempcrete’s breathability stops moisture buildup under floors or above ceilings, cutting down on mold risk.

Homeowners enjoy lower energy bills because less heat escapes their homes, which is great for saving money and shrinking the carbon footprint of any building project.

Wrapping Up

You learned today that, what is hempcrete and it is a smart, green choice for insulation. It keeps warmth in, fights off mold and fire, and lets your walls breathe easy. Using it can lower your bills while cutting down on carbon, too.

Anyone building or fixing up a place can give it a try without breaking the bank or losing sleep over tricky steps. Plenty of guides online show how others used this strong biocomposite for better comfort at home.