The industrial sector continually evolves, demanding new safety practices and continuous training to keep workers safe. . Traditional training methods often fall short of meeting the challenges posed by complex machinery, hazardous environments, and intricate workflows. Enter virtual reality [VR]—a transformative technology that is reshaping the way industrial training is conducted. By integrating custom virtual reality solutions, industries can create immersive, interactive, and highly effective training programs. This article explores the pivotal role of VR in industrial training and its potential to revolutionize workforce development.

Understanding Virtual Reality in Industrial Training

Virtual reality involves creating simulated environments that mimic real-world scenarios. These environments allow trainees to interact with virtual objects and situations in a safe and controlled manner. Custom virtual reality solutions are tailored to address specific training requirements, ensuring relevance and effectiveness. Through VR, industries can:

- Simulate hazardous environments without exposing workers to real risks.

- Provide hands-on experience with complex machinery.

- Deliver consistent training modules irrespective of geographical constraints.

The flexibility and adaptability of VR make it a valuable asset for industries ranging from manufacturing to energy and healthcare.

Key Advantages of Custom VR in Industrial Training

1. Enhanced Learning Experience

Traditional training often relies on manuals, videos, and classroom sessions, which may lack engagement and practical application. VR offers:

- Immersive Learning: Trainees are placed in realistic scenarios that closely replicate their work environment. This hands-on approach improves understanding and retention.

- Active Participation: VR encourages interaction, allowing trainees to practice tasks, make decisions, and observe the outcomes in real-time.

By engaging multiple senses, VR enhances the learning experience and ensures that knowledge is retained more effectively.

2. Improved Safety and Risk Management

Industrial training often involves scenarios that are inherently risky. For example, training for roles in construction, mining, or chemical processing can expose workers to potential hazards. Custom VR solutions mitigate these risks by:

- Simulating dangerous environments, such as fire outbreaks or equipment malfunctions.

- Allowing trainees to practice emergency responses without real-world consequences.

- Reducing the likelihood of accidents during on-the-job training.

By prioritizing safety, VR helps industries protect their workforce while maintaining operational efficiency.

3. Cost-Effectiveness

While the initial investment in virtual reality software development may seem significant, the long-term savings are substantial. VR reduces training costs by:

- Minimizing the need for physical equipment and materials.

- Lowering travel expenses by enabling remote training.

- Reducing downtime associated with traditional on-site training.

Additionally, VR-based training ensures consistent quality across all sessions, maximizing the return on investment.

4. Real-Time Feedback and Assessment

Custom VR solutions integrate performance tracking features, enabling trainers to assess trainees’ skills and progress in real-time. These features include:

- Immediate feedback on task performance.

- Detailed analytics on decision-making and response times.

- Personalized recommendations for improvement.

With these insights, trainers can tailor their approach to address individual learning needs, ensuring a more effective training experience.

5. Scalability and Adaptability

Custom VR solutions are highly scalable, making them suitable for businesses of all sizes. Whether training a small team or a large workforce, VR can adapt to varying requirements. Furthermore:

- Training modules can be updated easily to reflect new protocols or technologies.

- VR environments can be customized to simulate specific industrial setups or workflows.

This adaptability ensures that training remains relevant and up-to-date, even as industries evolve.

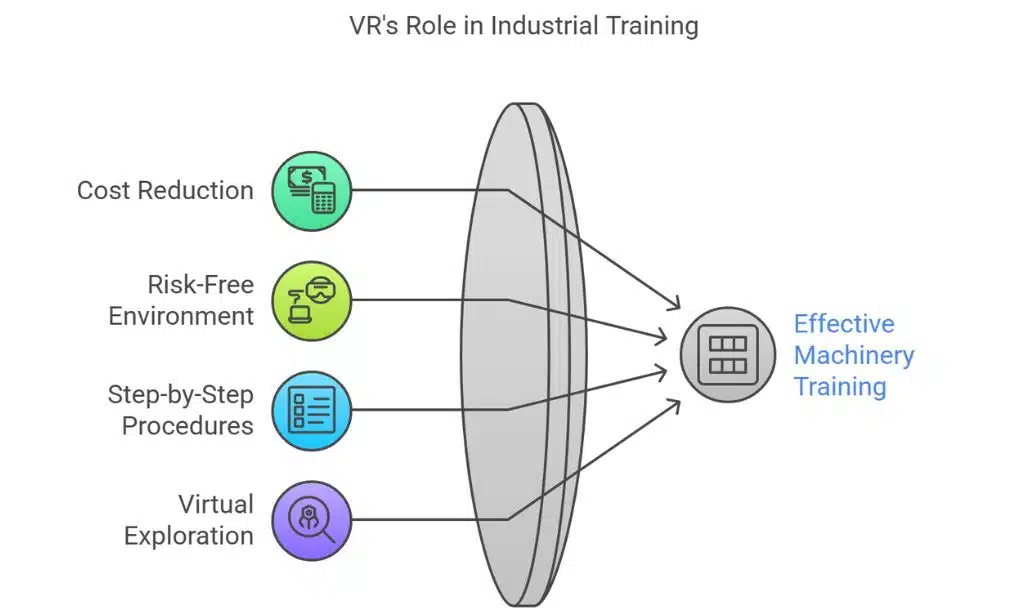

Applications of VR in Industrial Training

1. Machinery Operation and Maintenance

Training workers to operate and maintain complex machinery often requires access to expensive equipment. VR eliminates these challenges by:

- Simulating machinery operations, allowing trainees to practice in a risk-free environment.

- Demonstrating maintenance procedures step-by-step.

- Enabling trainees to explore machinery components virtually for a better understanding.

This approach reduces wear and tear on actual equipment and ensures trainees are well-prepared before handling real machinery.

2. Emergency Response Training

Industries such as oil and gas, manufacturing, and aviation require employees to respond effectively to emergencies. VR excels in this area by:

- Simulating emergency scenarios, such as chemical spills, explosions, or natural disasters.

- Training employees in evacuation protocols and first-aid procedures.

- Testing decision-making skills under pressure.

By preparing workers for emergencies, VR enhances overall workplace safety and readiness.

3. Soft Skills Development

While technical skills are critical, soft skills such as communication, teamwork, and leadership are equally important. VR can:

- Create scenarios that require trainees to interact with virtual colleagues or clients.

- Simulate conflict resolution and negotiation situations.

- Enhance cultural sensitivity and diversity training through realistic role-playing.

These applications ensure that employees are well-rounded and capable of handling various workplace challenges.

4. Remote and Global Training

For multinational companies, delivering consistent training across locations is a challenge. VR bridges this gap by:

- Offering standardized training modules accessible from anywhere.

- Reducing logistical constraints, such as travel and accommodation.

- Ensuring uniformity in training quality across global teams.

This capability is particularly valuable in today’s increasingly remote work environment.

Challenges and Considerations

While VR holds immense potential, certain challenges must be addressed for successful implementation:

- Cost of Development: Developing custom VR solutions requires significant investment. However, the long-term benefits often outweigh the initial costs.

- Technological Infrastructure: Reliable hardware and software infrastructure are essential for a seamless VR experience.

- User Adoption: Employees unfamiliar with VR technology may require initial orientation to maximize its benefits.

By addressing these challenges, industries can fully harness the power of VR for training purposes.

Takeaways

Custom virtual reality is transforming industrial training by providing immersive, safe, and efficient learning experiences. Through tailored VR solutions, industries can enhance workforce skills, improve safety standards, and achieve cost savings. The integration of real-time feedback, scalability, and adaptability ensures that VR-based training remains relevant in an ever-changing industrial landscape. As virtual reality software development continues to advance, its role in industrial training will only grow, paving the way for a more skilled and prepared workforce.